Air-controlled pneumatic synchronous wiper for locomotive

An air-controlled, locomotive technology, applied in the field of air-controlled synchronous pneumatic wiper devices for locomotives, can solve the problems of high manufacturing and maintenance costs, complex structure of wipers, inability to adapt to synchronous wipers, etc., and achieves low production cost, installation Safe and reliable connection, good scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

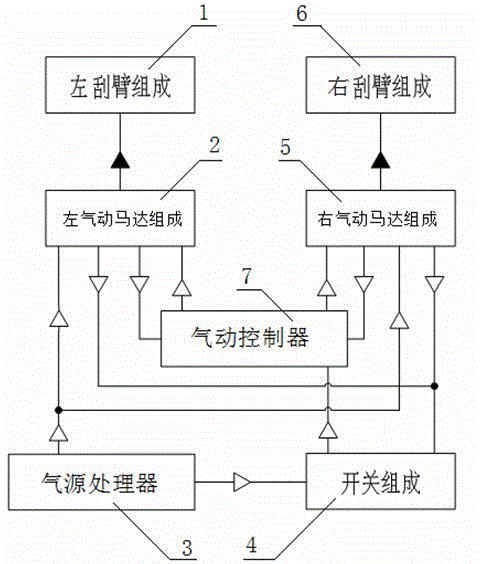

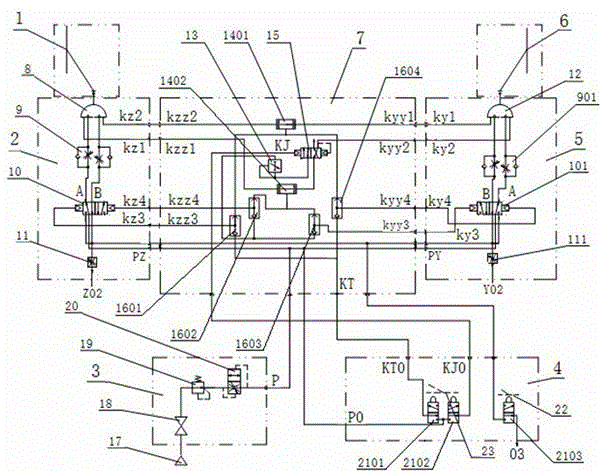

[0022] The air-controlled synchronous pneumatic wiper device for locomotives of the present invention comprises a left scraping arm composition 1, a left air motor composition 2, an air source processor 3, a switch composition 4, a right air motor composition 5, a right scraping arm composition 6 and a pneumatic control Device 7, left air motor composition 2, gas source processor 3, switch composition 4, right air motor composition 5 and pneumatic controller 7 are connected by connecting air pipe.

[0023] The left air motor forms 2, which is composed of a left swing cylinder 8, a left one-way throttle valve 9, and a left two-position five-way valve 10, which are connected by connecting air pipes successively. The discharge port of the left two-position five-way valve 10 is connected with a left speed-regulating throttle valve 11, and the outlet of the left speed-regulating throttle valve 11 is connected with a left discharge port Z02 which communicates with the atmosphere. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com