Corrosion resistant and high wear resistant sink roll

A sunken roll, anti-corrosion technology, applied in coating, metal material coating process, hot dip plating process and other directions, can solve the problems of large sliding surface damage of sunken roll, poor wear resistance of sunken roll, increased production cost, etc. The effect of solving the nodule problem, good corrosion resistance and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the present invention will be further explained based on the drawings and the embodiments.

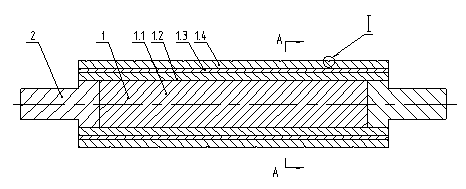

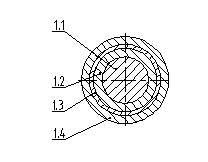

[0017] The anti-corrosion and high wear-resistant submerged roller shown in the figure includes a cylindrical roller body 1, a roller shaft 2 connected to the two ends of the roller body 1; the roller body 1 includes alloy sleeves 1.2, which are distributed radially from the inside to the outside. The cermet sleeve 1.3, the sealing agent layer 1.4; the alloy sleeve 1.2 is provided with a lead core 1.1.

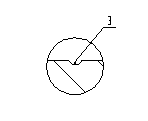

[0018] In this embodiment, the surface of the roller body 1 is provided with spiral grooves 3 to solve the problem of nodules on the surface of the roller and improve the quality of the product.

[0019] In order to achieve a better conveying effect, the bottom of the spiral groove 3 is arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com