Highway pavement structure taking building rubbish as aggregate

A technology for pavement structure and construction waste, which is applied to cohesive pavement, buildings, roads and other directions paved on site, which can solve the problems of poor strength, stiffness and stability that cannot meet the pavement structure requirements of grade roads, and achieve good strength , Improve the degree of compactness and save the cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

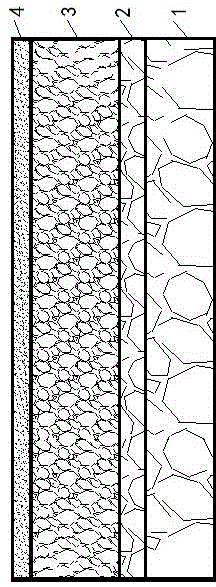

[0036] As a preferred embodiment of the present invention, it includes a base layer, a base layer, a base layer and a surface layer laid in sequence from bottom to top; the materials of the base layer and the base layer are waste concrete, and the waste concrete used for the base layer is The particle size is 50-150mm; the base layer is waste concrete with a particle size of 9.5-26.5mm; the base layer is aggregate with a particle size of 4.75-40mm; the surface layer is a surface layer with a particle size of 2.36-20mm aggregate.

Embodiment 2

[0038]As the best implementation mode of the present invention, the present invention is a "large-small-medium-thin" road structure, which is respectively from bottom to top: foundation treatment adopts large blocks of construction slag with a main particle size of 100 mm; Gradation of small pieces of building slag with a particle size of 10-20mm; middle block of building slag with a particle size of 4.75-40mm (including a certain proportion of crushed stones) for the base layer; building slag and crushed stones of 2.36-20mm for the surface layer.

[0039] In the present invention, the roadbed pavement structure layer design is as follows: figure 1 Shown:

[0040] In the structural layer 1 mentioned in the figure, the composition of the material: large pieces of waste concrete.

[0041] In the structural layer 2 mentioned in the figure, the composition of the material: broken waste concrete blocks.

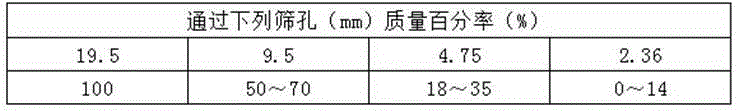

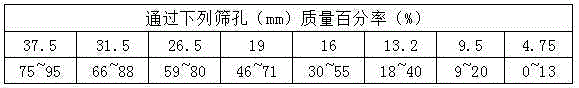

[0042] In the structure layer 3 shown in the figure, there are four options...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com