Road semi-rigid base waste recycled concrete and preparation method thereof

A semi-rigid base and recycled concrete technology, which is applied in the field of civil engineering materials, can solve the problems of serious environmental damage effects, high power consumption, and mountain damage, and achieve the effects of saving manpower and material resources, reducing raw material costs, and reducing pollution and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

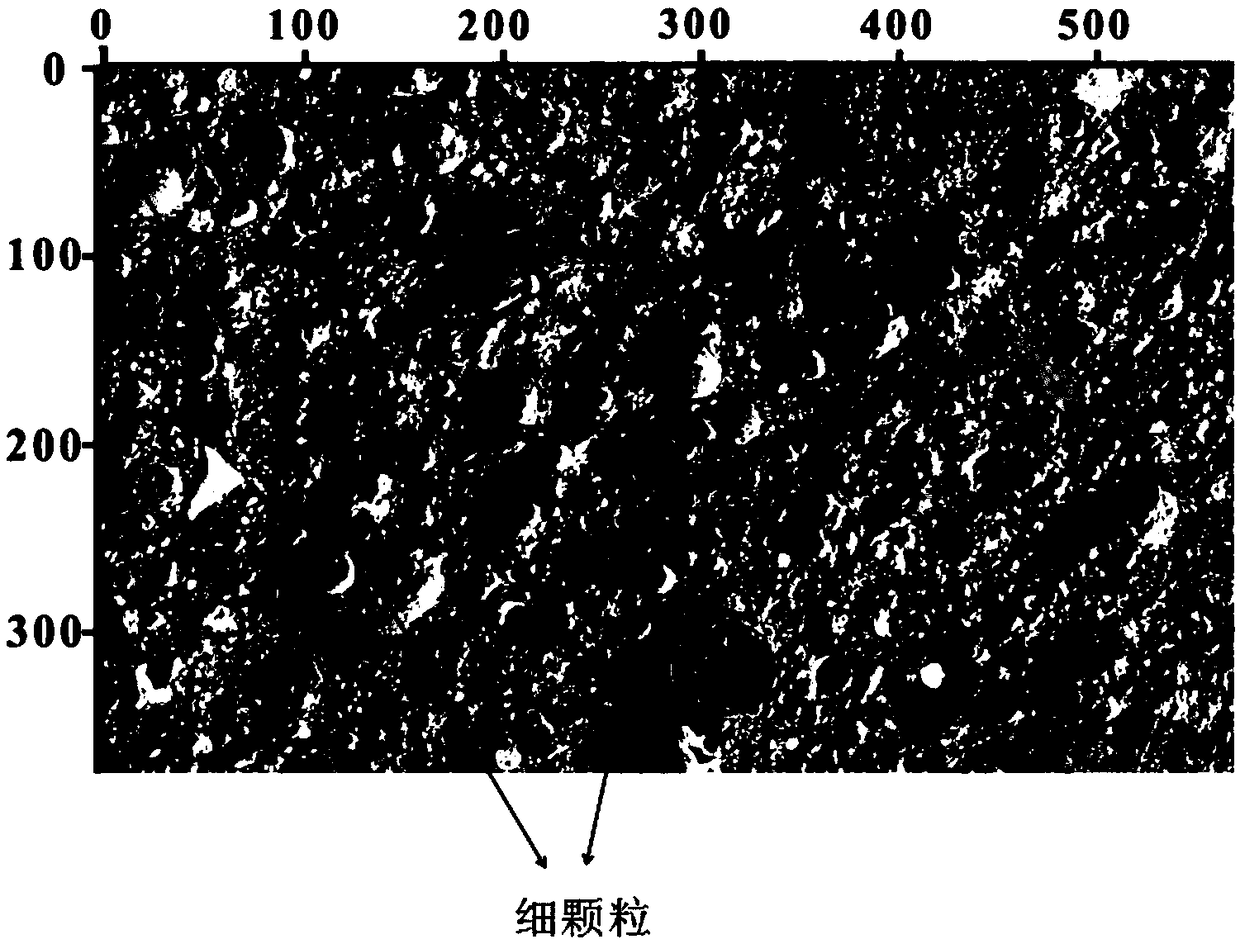

Embodiment 1

[0036] The pavement semi-rigid base waste regenerated concrete of this embodiment is made of the following components by mass: 1500 parts of semi-rigid base waste, 450 parts of 42.5 ordinary Portland cement, 270 parts of Class I fly ash, and 210 parts of silica fume. 30 parts of quicklime powder, 10 parts of iron powder, 100 parts of iron-containing polypropylene fiber, 41 parts of concrete regeneration agent, and 311 parts of water; the semi-rigid grassroots waste is first milled and then crushed until the particle size does not exceed 0.6mm The primary material; the silica fume is amorphous spherical particles, SiO in silica fume 2 The mass content of not less than 83%, SiO 2 The specific surface area is not less than 15m 2 / g; the main components of the concrete regeneration agent are: isoprenyl polyoxyethylene ether, hydrogen peroxide, vinyltriethoxysilane, sodium hydroxide, ferrous sulfate, acrylic acid, methallyl Polyethylene glycol macromonomer, acrylic acid, ammonium...

Embodiment 2

[0043] The pavement semi-rigid base waste regenerated concrete of this embodiment is made of the following components by mass: 780 parts of semi-rigid base waste, 500 parts of 42.5 ordinary Portland cement, 57 parts of Class I fly ash, and 30 parts of silica fume. 100 parts, 100 parts of iron-containing polypropylene fiber, 36 parts of concrete regeneration agent, 255 parts of water; the semi-rigid base waste material is milled and then crushed to a particle size of no more than 0.6mm primary material; the silica fume is Shaped spherical particles, SiO in silica fume 2 The mass content of not less than 83%, SiO 2 The specific surface area is not less than 15m 2 / g; the main components of the concrete regeneration agent are: isoprenyl polyoxyethylene ether, hydrogen peroxide, vinyltriethoxysilane, sodium hydroxide, ferrous sulfate, acrylic acid, methallyl Polyethylene glycol macromonomer, acrylic acid, ammonium persulfate, mercaptoacetic acid, branched active macromonomer and ...

Embodiment 3

[0049] The pavement semi-rigid base waste regenerated concrete of this embodiment is made of the following components by mass: 1900 parts of semi-rigid base waste, 400 parts of 42.5 ordinary Portland cement, 400 parts of Class I fly ash, and 240 parts of silica fume. 100 parts, 100 parts of iron-containing polypropylene fiber, 80 parts of concrete regeneration agent, and 230 parts of water; the semi-rigid base waste material is milled and then crushed to a particle size of no more than 0.6mm; the silica fume is Shaped spherical particles, SiO in silica fume 2 The mass content of not less than 83%, SiO 2 The specific surface area is not less than 15m 2 / g; the main components of the concrete regeneration agent are: isoprenyl polyoxyethylene ether, hydrogen peroxide, vinyltriethoxysilane, sodium hydroxide, ferrous sulfate, acrylic acid, methallyl Polyethylene glycol macromonomer, acrylic acid, ammonium persulfate, mercaptoacetic acid, branched active macromonomer and sodium bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com