A method of weakening the bridge deck system to participate in the joint action of the main truss

A joint action and bridge deck system technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of complex connection structure, increased steel consumption, and increased bridge maintenance work, and achieve simple connection structure, simplified section type, and reduced The effect of maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

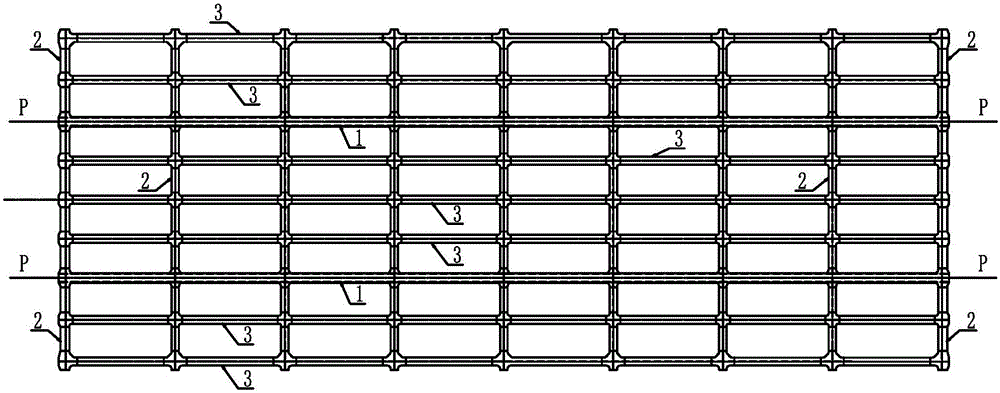

[0008] refer to figure 1 , the present invention is aimed at the bridge deck structure with longitudinal girders 3 and cross girders 2, the main truss chords are connected, the bridge deck cross girders 2 are connected with the main truss chords 1, and all the longitudinal girders 3 are not installed earlier. According to the relative deformation of the main truss chord and the bridge deck longitudinal girder caused by the joint action of the bridge deck system, a pre-stress P is applied symmetrically at both ends of the main truss chord 1 to force the main truss chord to compress and deform, and the main truss chord When the compression deformation reaches the joint effect, the relative deformation of the main truss chord and the deck longitudinal girder is consistent, and the bridge deck longitudinal girder is installed. The longitudinal girder of the bridge deck is manufactured according to the shortened distance of the main truss. After the bridge deck longitudinal girder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com