Production method of double-sided forward pouring of gypsum composite thermal insulation wallboard without cold bridge

A production method and composite thermal insulation technology are applied in the field of casting and forming of residential building wall parts to achieve the effect of tight composite structure and firm anchoring and bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

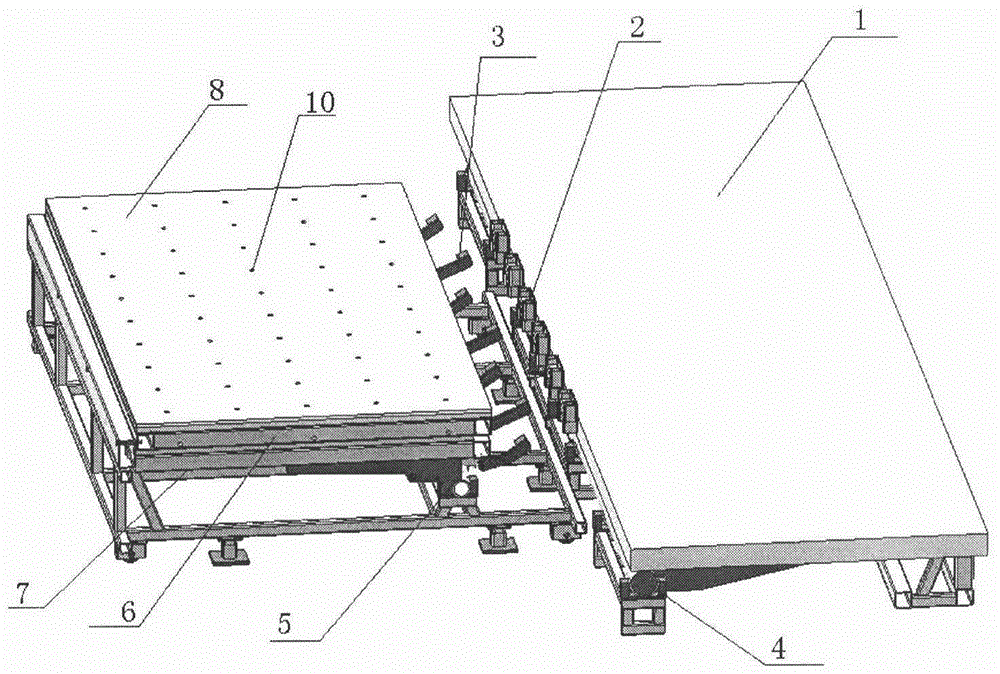

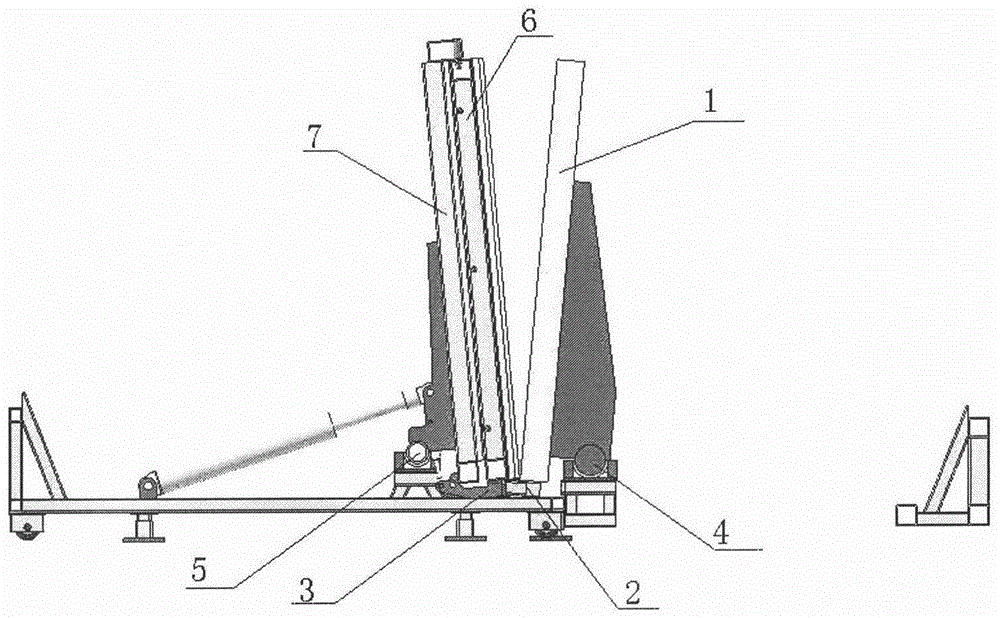

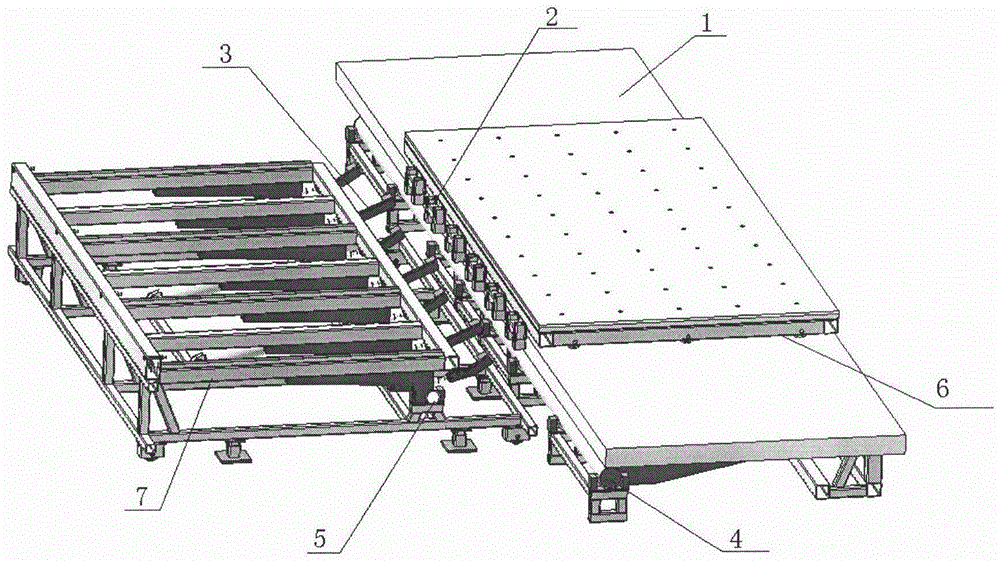

[0027] Below in conjunction with accompanying drawing, the present invention is further described in detail: no cold bridge gypsum composite thermal insulation wallboard double-sided forward pouring production method, according to the following steps:

[0028] A. Place the pre-prepared insulating layer 8 with connecting ribs on the wallboard drawer frame 6, so that the umbrella head of the connecting rib 10 falls into the keel gap of the wallboard drawer frame 6, and the wallboard drawer frame 6 supports Live insulation laminate 8. When the insulation layer 8 is prepared in advance, both sides are roughened and grooved. The horizontal groove depth is 3mm and the width is 6mm. The length of each petal of the head is 11mm, and the included angle with the insulating layer board 8 is 40°-60°. The thermal insulation laminate 8 treated in this way has enhanced the bonding force between the gypsum composite cementitious material layer 9, and the umbrella head of the connecting rib 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com