Compressor exhaust system and exhaust method thereof

A compressor exhaust and compressor technology, which is applied in the direction of compressors, refrigerators, fluid circulation arrangements, etc., can solve the problems that the compressor exhaust temperature and compressor performance cannot be improved well, so as to ensure safety and The effect of long service life, simple modification process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

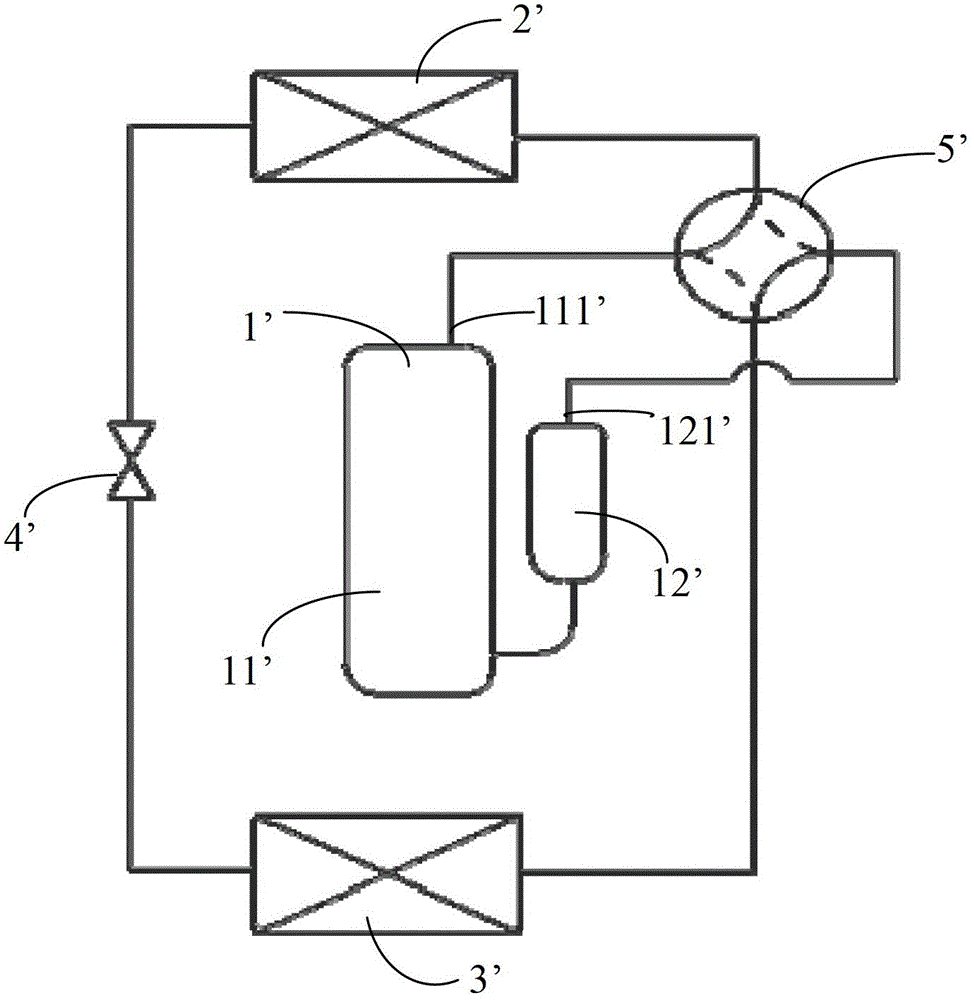

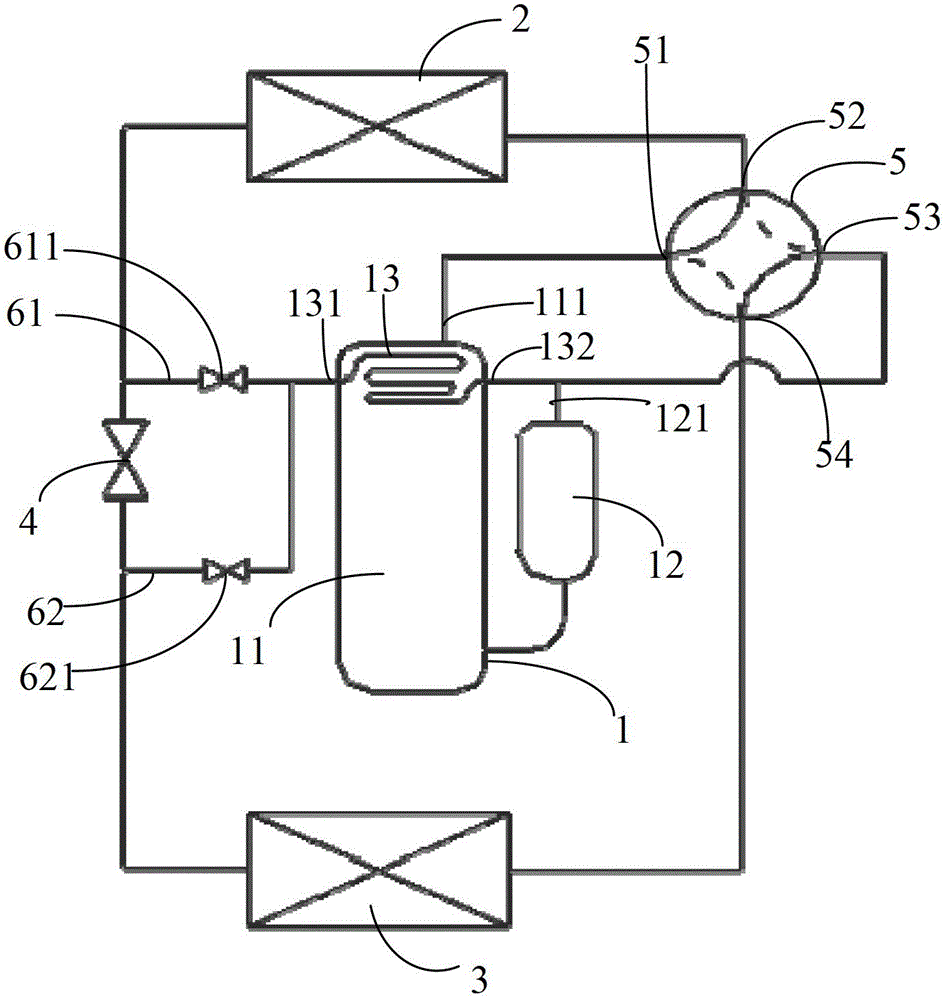

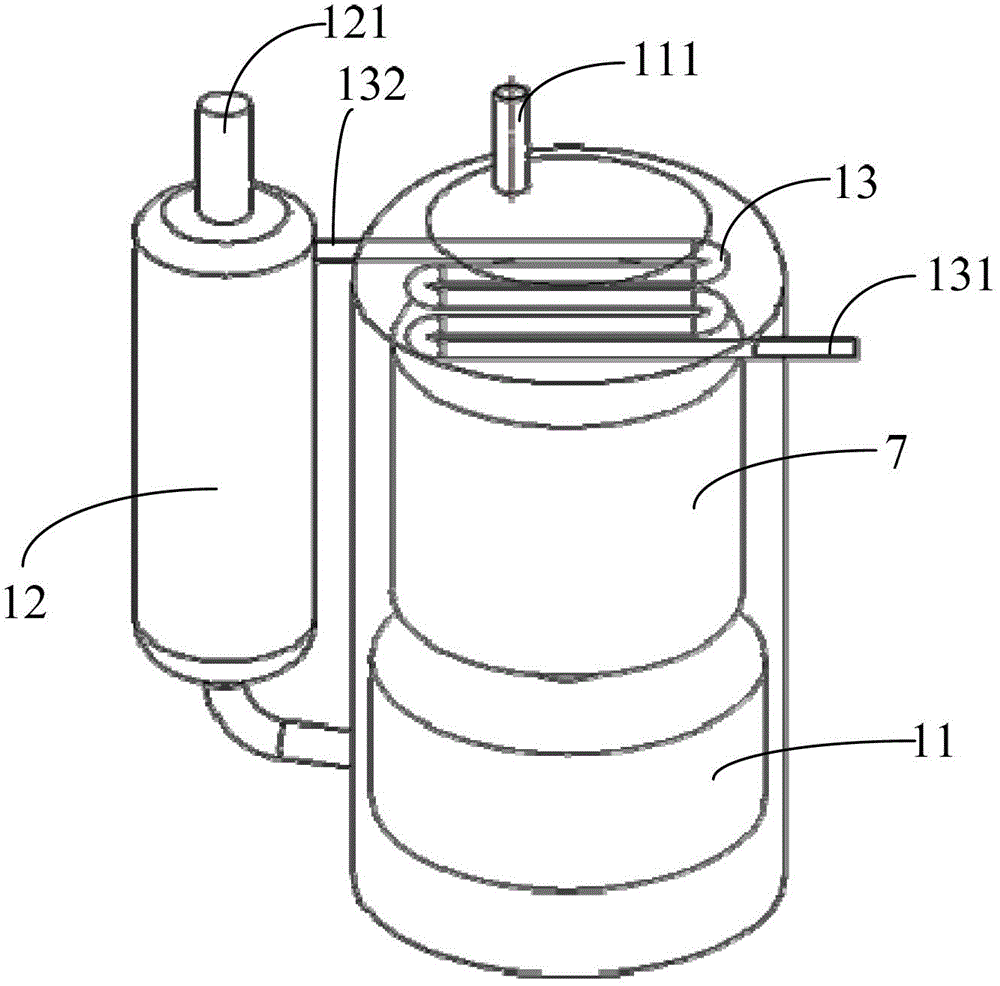

[0034] The invention discloses a compressor exhaust system, comprising a compressor, a condenser and an evaporator connected with the compressor, a throttling device and a four-way valve between the condenser and the evaporator, the throttling device and a four-way valve The valves are respectively located on both sides of the condenser and evaporator. The compressor is equipped with a coil for heat exchange. The coil includes a coil inlet and a coil outlet. The side of the coil is connected to form the first branch and the second branch. The outlet of the coil is connected to the four-way valve. The compressor is equipped with an exhaust port and an air suction port connected to the four-way valve. The exhaust port is equipped with a temperature measurement device.

[0035] Preferably, a first solenoid valve and a second solenoid valve are respectively provided on the first branch and the second branch, and the first solenoid valve and the second solenoid valve respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com