Device and method for detecting surface defect on strip steel

A defect detection and strip technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as imaging technology not involved in the visual inspection system, and achieve the effect of improving the detection effect and avoiding the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

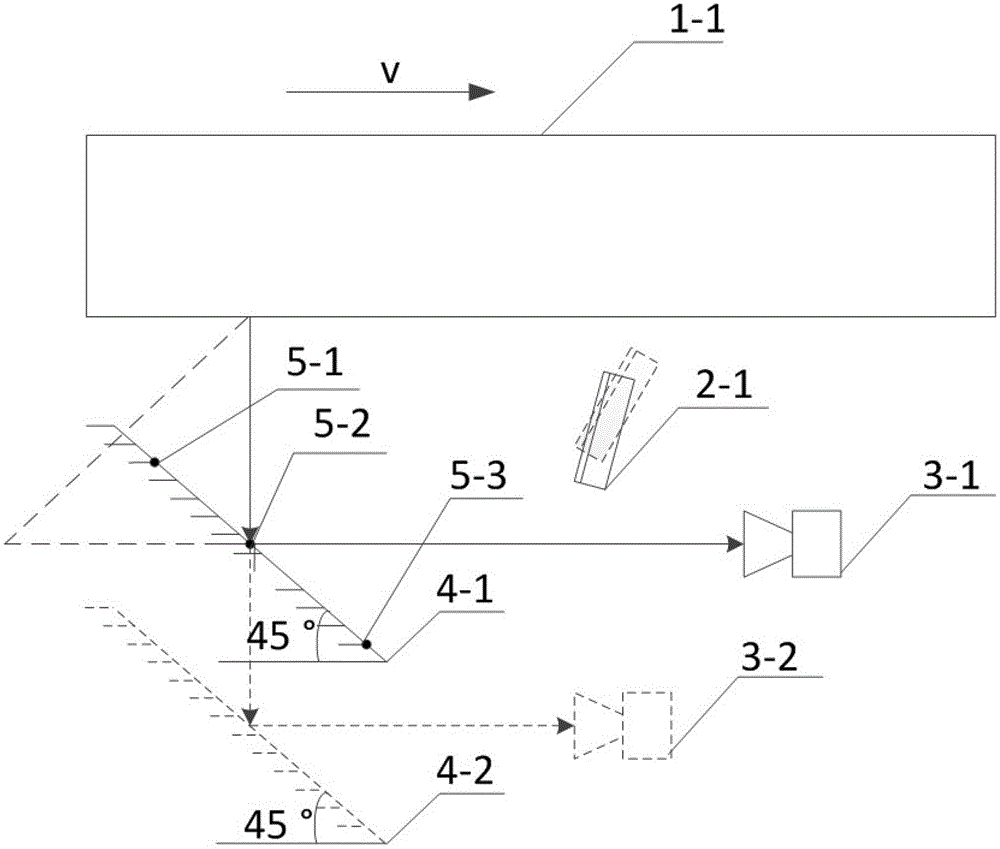

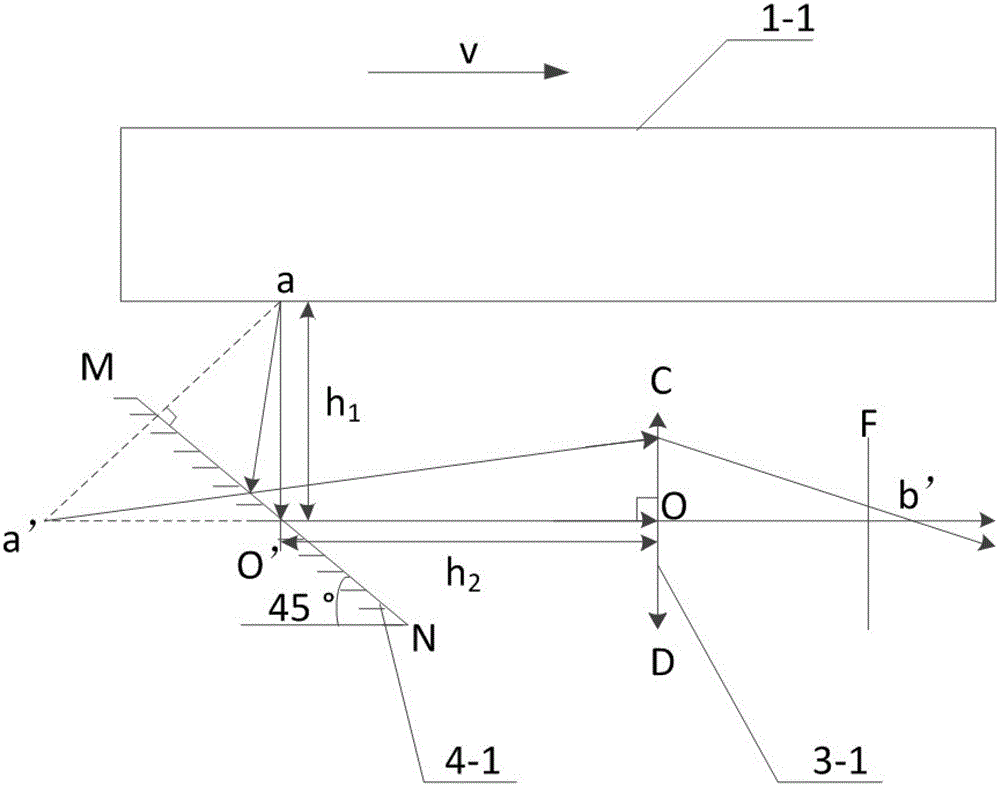

[0052] Such as image 3 As shown, according to the pre-calculated imaging distance H, and according to the actual conditions of the lower surface space on site, the vertical distance h of the lower surface is calculated 1 , and calculate the horizontal distance h at the same time 2 =H-h 1 . Arrange the position of the reflector 4-1 and its CCD camera 3-1 of the steel lower surface 1-1 according to this distance, such as figure 1 shown. Determine the illumination mode of the light source (bright field illumination or dark field illumination) according to the previous experimental plan, and determine the illumination angle of the light source 2-1.

[0053] First, according to Figure 5 The flow automatically adjusts the illumination of the light source, and then the CCD camera 3-1 will obtain the strip steel information through the imaging reflector 4-1. The surface morphology of the steel strip is the surface morphology of the steel strip obtained after being reflected by...

Embodiment 2

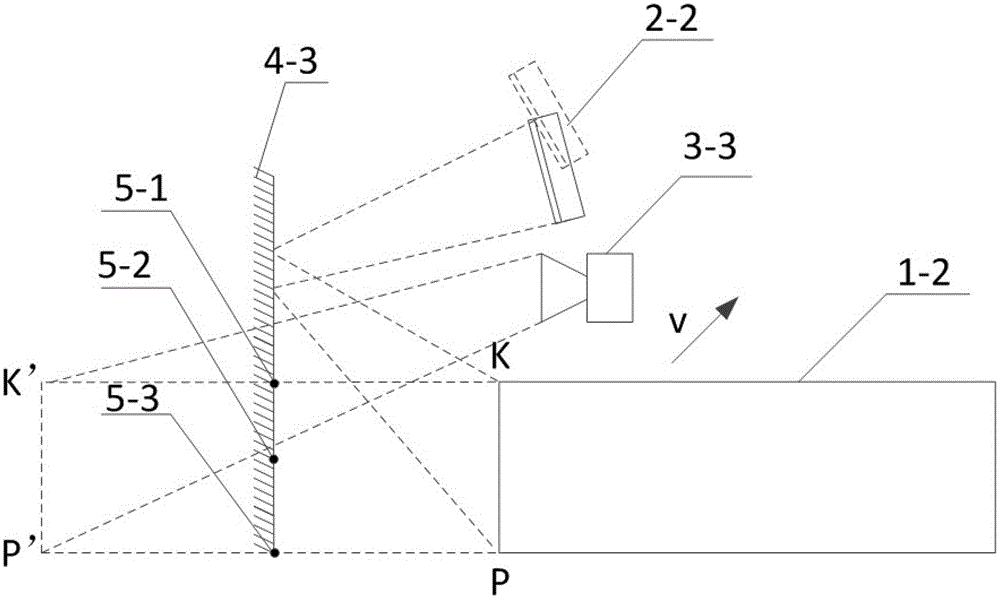

[0056] Such as figure 2 As shown, first determine the lighting position of the light source according to the image acquisition position and the actual side space position of the thick plate on site, and arrange the position of the light source 2-2 and the position of the light source reflector 4-3. Calculate the imaging distance according to the preset resolution, and arrange the positions of CCD cameras 3-3.

[0057] according to Figure 5 The flow automatically adjusts the illumination of the light source, and then the CCD camera 3-3 will obtain the steel strip information through the imaging reflector 4-3. At the same time, the light source 2-2 illuminates the defective surface through the reflector 4-3, and the equipped angle adjustment mechanism can adjust the angle of the light source at any time to ensure the matching of the lighting mode. The quality of the images collected by the CCD camera 3-3 can also reflect the cleanliness of the mirror surface in time. Once th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com