Optical fiber ribbon cable stripping protector

A ribbon-shaped optical cable and protector technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of high cost, inconvenient operation, cumbersome processing, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

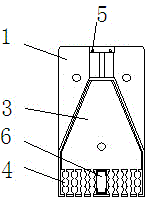

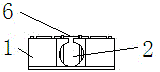

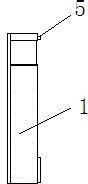

[0018] Such as figure 1 A ribbon-shaped optical cable stripping protector shown in —5 includes a bottom box 1 and a cover plate 7 installed on the bottom box 1, and the bottom box 1 is provided with a cable inlet 2, a wire feeding groove 3 and a fiber splitting The fiber outlet vertical slot 4, the cable inlet hole 2 communicates with the wire feeding slot 3, and the wire feeding slot 3 communicates with the fiber splitting and fiber output vertical slot 4; the bottom box 1 is equipped with a positioning pin 5 and a snap ring frame 6. The bottom box 1, the cable inlet hole 2, the wire feeding groove 3, the fiber splitting fiber outlet vertical groove 4, the positioning pin 5 and the snap ring frame 6 are injection molded at one time; the bottom box 1 passes through the positioning pin 5, the snap ring The frame 6 is connected with the cover plate 7; the cover plate 7 is equipped with a buckle 8, and the cover plate 7 is provided with a positioning hole 9, the snap ring frame 6...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap