Liquid crystal lens manufacturing method and liquid crystal lens

A technology of liquid crystal lens and manufacturing method, which is applied in the field of liquid crystal, can solve the problems of low utilization rate of optical path difference of liquid crystal lens, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

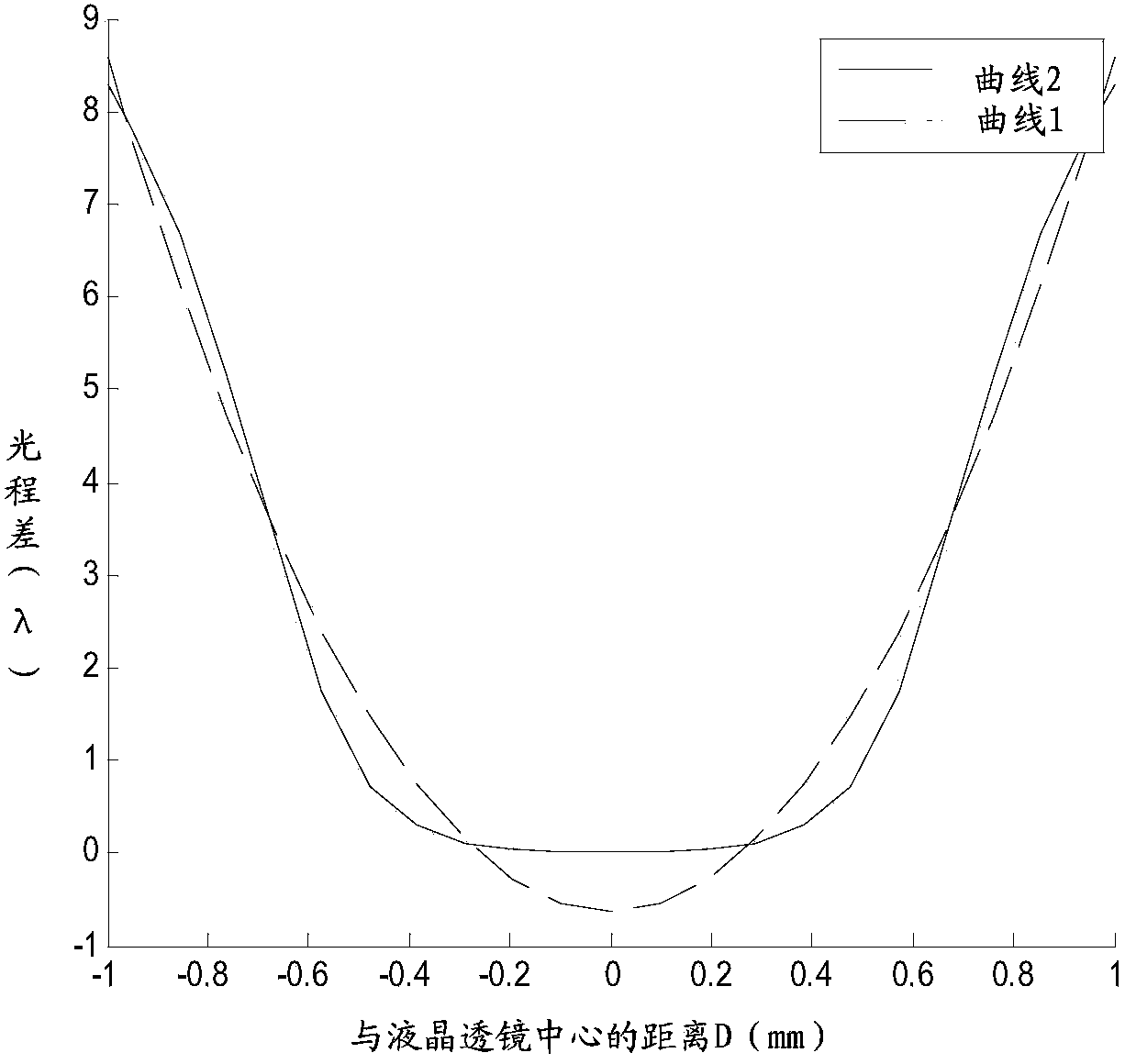

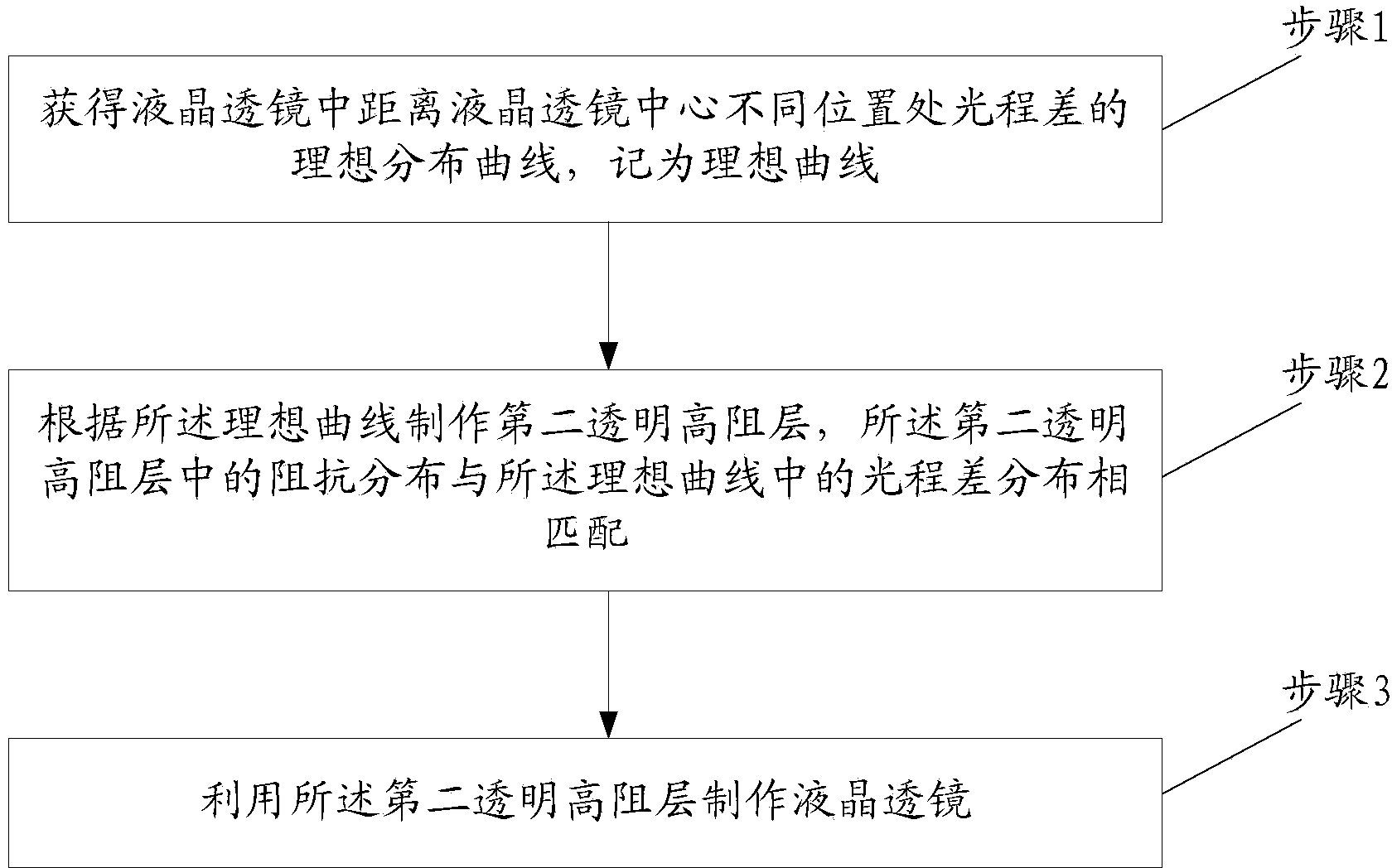

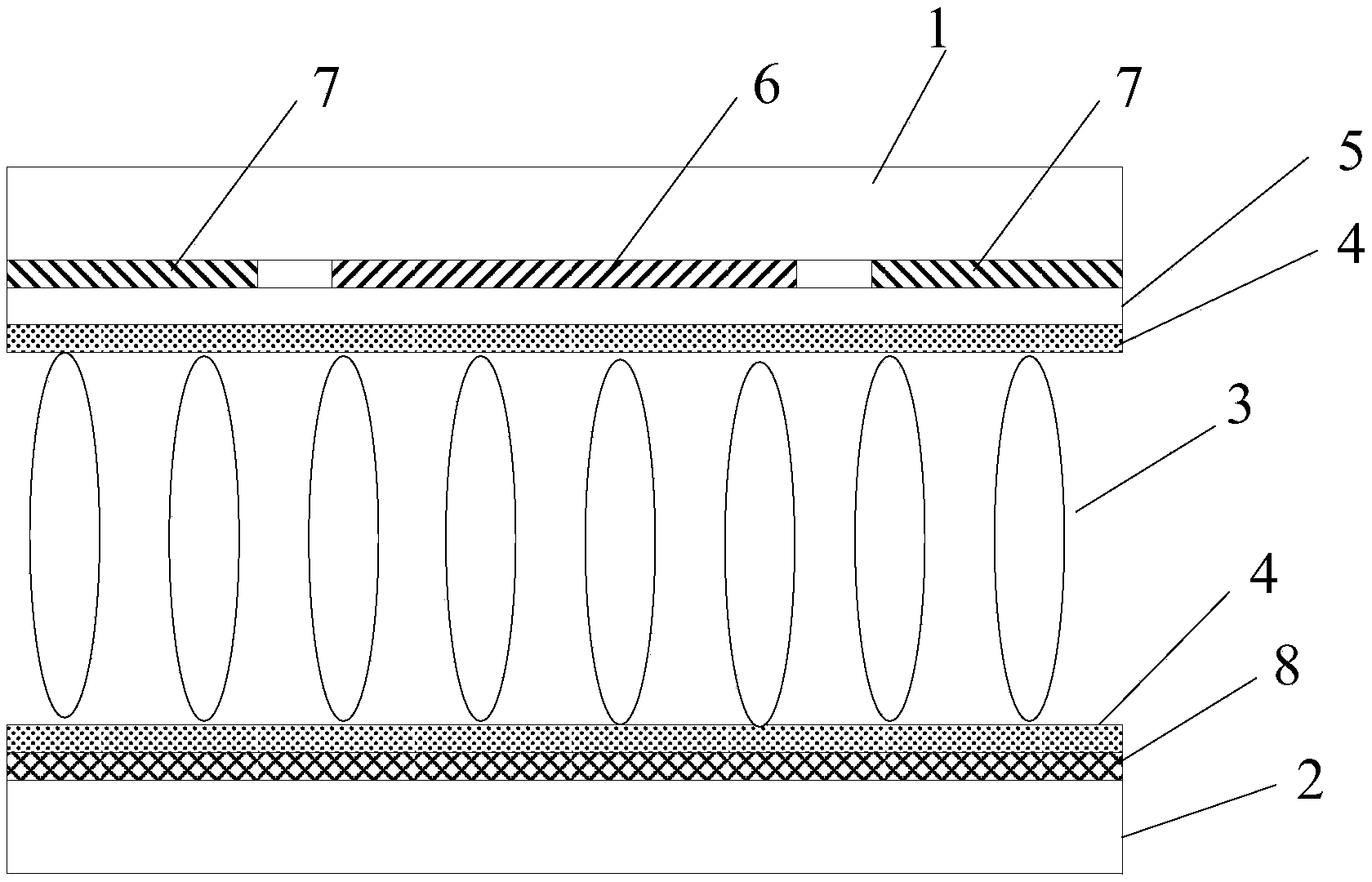

[0052] As mentioned in the background art section, the utilization rate of the optical path difference of the liquid crystal lens in the prior art is relatively low.

[0053]The inventors found that the reason is that the utilization rate of the optical path difference of the liquid crystal lens is determined by the properties of the liquid crystal molecules in the liquid crystal layer and the voltage applied across the liquid crystal layer. When all the liquid crystal molecules in the liquid crystal layer are reversed, the optical path difference of the liquid crystal lens is the maximum optical path difference: the refractive index Δn of the liquid crystal molecules in the liquid crystal layer is multiplied by the thickness d of the liquid crystal lens. However, when a voltage is applied to both ends of the liquid crystal layer, since the liquid crystal layer is provided with an alignment film facing the upper substrate and the lower substrate, the molecules in the liquid cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com