Compression resin packaging method and compression resin packaging device for electronic components

A technology for electronic component installation and electronic components, which is applied in the direction of electrical components, electric solid devices, circuits, etc., and can solve problems such as inability to form packages with thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

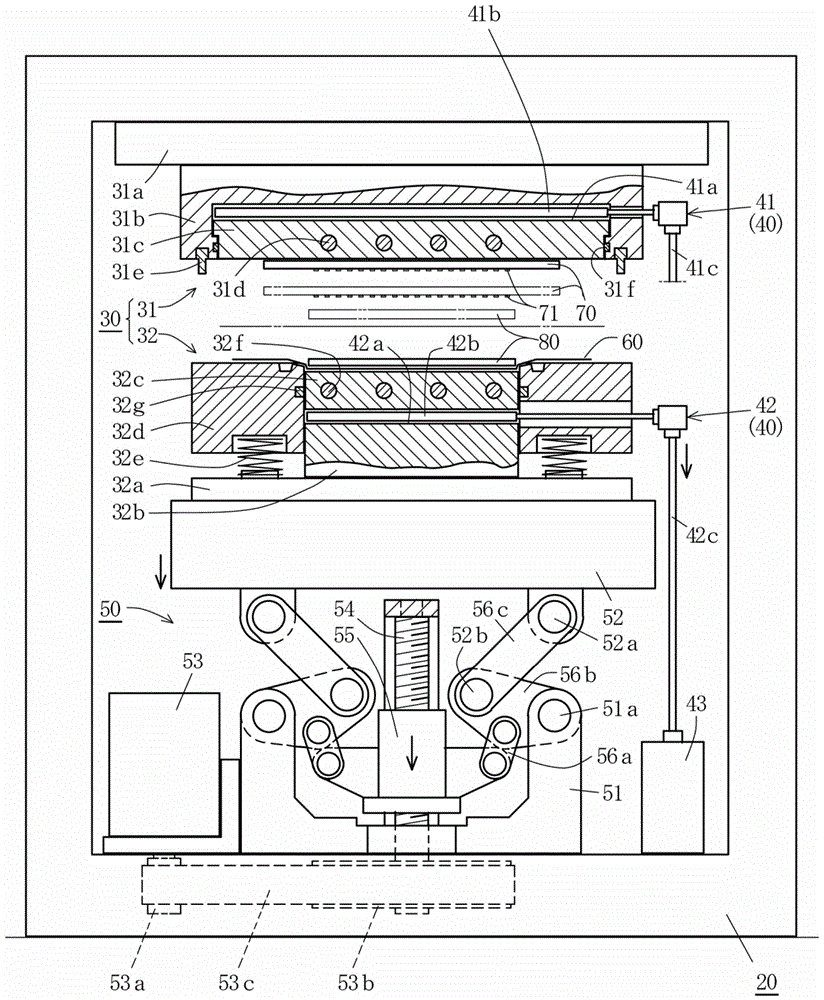

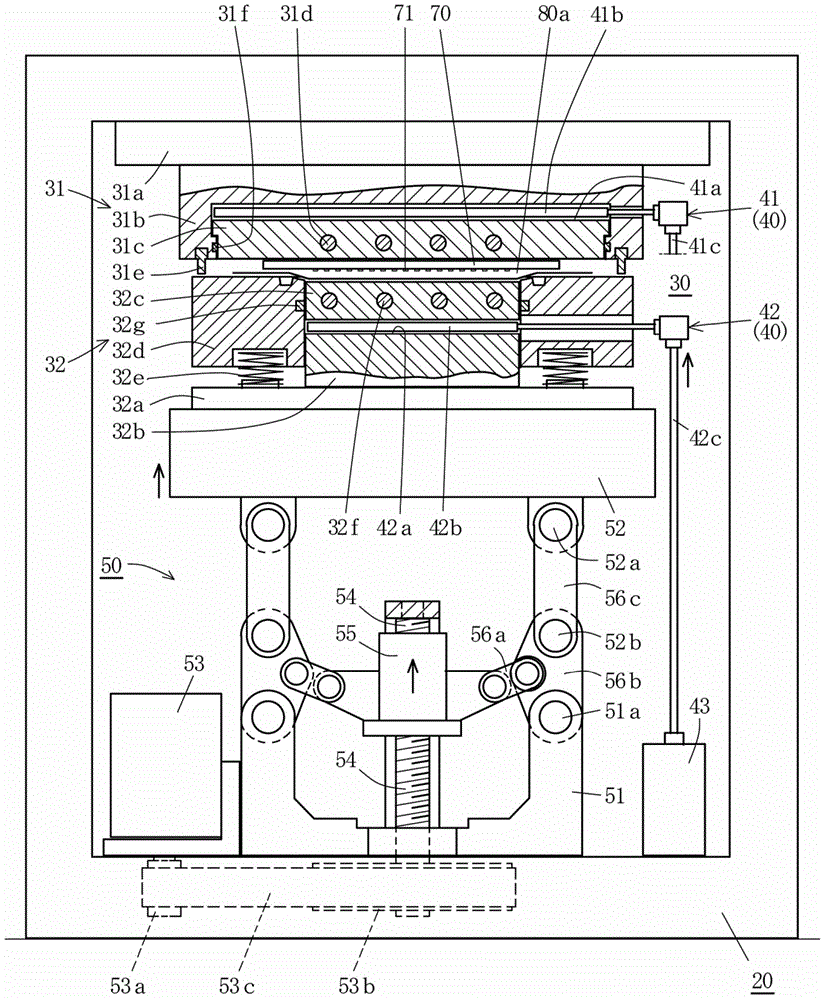

[0086] Figure 1 to Figure 5 is the first embodiment of the present invention, figure 1 and figure 2 shows the overall structure of the compressed resin encapsulation device, and, in addition, Figure 3 to Figure 5 Indicates its main part.

[0087] In addition, this compression resin packaging device shows a structure in which each component is held by a press frame (holder). That is, an upper die 31 for compression molding is disposed on the lower surface side of the upper end portion of the frame-shaped press frame 20, and a die opening and closing mechanism 50, which will be described later, is disposed below the upper die 31 so that it can move up and down. A lower mold 32 for compression molding is provided. The upper mold 31 and the lower mold 32 constitute a mold 30 for compression molding.

[0088] In addition, the upper mold 31 includes: an upper mold base 31a fixedly installed on the lower surface side of the upper end of the pressing frame 20; an upper mold h...

no. 2 approach )

[0110] Below, based on Figure 6 A second embodiment of the present invention will be described.

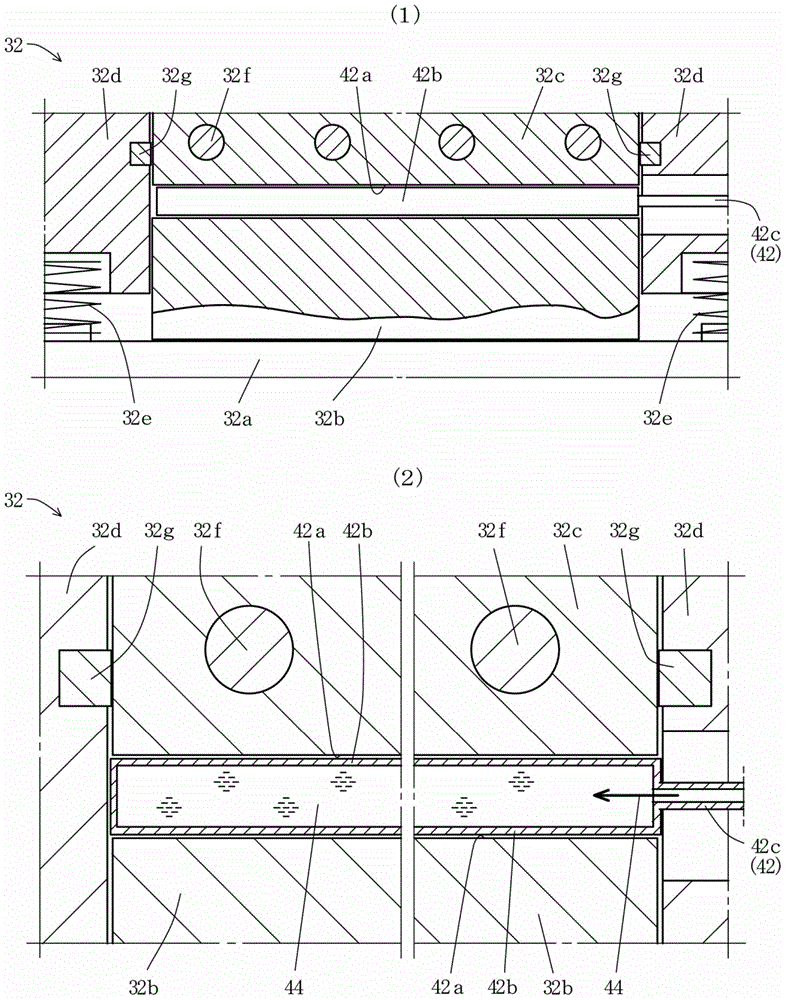

[0111] Figure 6 is a compression resin sealing device showing a second embodiment of the present invention, Figure 6 (1) indicates the main part of the resin molding part when the upper and lower molds are opened. In addition, Figure 6 (2) indicates the main part of the resin molded part when the upper and lower molds are clamped. The second embodiment differs from the first embodiment in the following points. In addition, other points are substantially the same as those of the first embodiment. Therefore, different points will be described, and the same reference numerals will be used for substantially the same components as those of the first embodiment, and duplication of description will be avoided.

[0112] That is, if Figure 6 As shown in (2), a narrow gap 34c for allowing the remaining resin 80b to flow out of the lower mold cavity 34a is provided between the mol...

no. 3 approach )

[0118] Figure 7 is a compression resin sealing device showing a third embodiment of the present invention, Figure 7 (1) indicates the main part of the resin molding part when the upper and lower molds are opened. In addition, Figure 7 (2) indicates the main part of the resin molded part when the upper and lower molds are clamped. The third embodiment differs from the first and second embodiments in the following points. In addition, other points are substantially the same as those of the first and second embodiments. Therefore, different points will be described, and the same reference numerals will be used for components that are substantially the same as those in the first and second embodiments, and duplication of description will be avoided.

[0119] That is, if Figure 7 As shown, the lower mold 32 has a cavity bottom surface (cavity bottom surface member 32c of the first and second embodiments) and a cavity side surface (cavity side surface member 32d of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com