Electric driver for motor vehicle

A technology for electric drives and motor vehicles, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as unfavorable and high installation costs, and achieve the effect of improving interference removal, spark interference removal, and interference removal degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

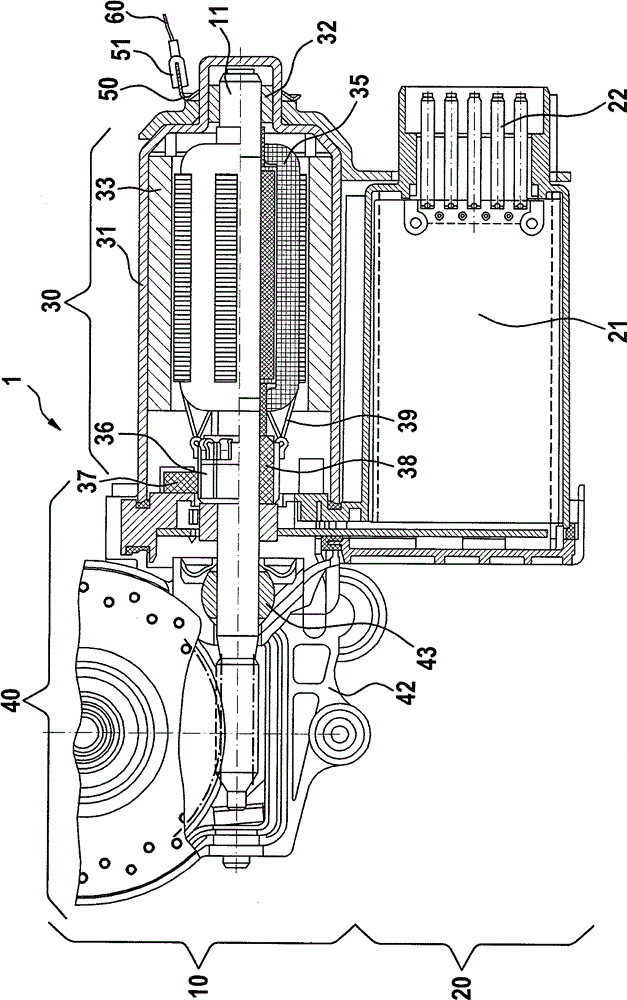

[0022] figure 1 A longitudinal section through an electric drive 1 according to the invention is shown with a drive module 10 and an electronics module 20 , the drive module 10 comprising a motor module 30 and a transmission module 40 . In this case, the motor module 30 is shown in section in the upper part and in a cutaway view in the lower part. Brushes 37 and commutator laminations 38 can be seen in the upper cutaway. Furthermore, the motor module 30 includes an armature 35 which is connected to the direct current grid via a commutator 36 . The commutator 36 is connected to the armature 35 via a connecting hook 39 . Since the corresponding winding inductance is short-circuited via the winding resistance and the brush transition resistance when the brush 37 moves from one segment 38 to the next, a commutation occurs during operation of the motor module 30 at each commutation. spark discharge. Such sparkovers on the one hand shorten the service life of the motor module 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com