Sealing Sheet for Solar Cells

A solar cell and sealing sheet technology, which is used in household sealing, applications, circuits, etc., can solve the problem of unwinding the sealing sheet for solar cells smoothly, and achieve the effect of less air residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

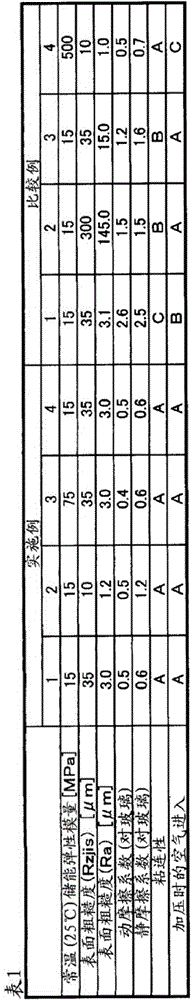

[0166] 95 parts by mass of an ethylene-octene random copolymer (manufactured by Dow Chemical Co., Ltd., trade name: Engage 8200, MFR: 5, octene content: 10.1 mol%) as an ethylene-α-olefin random copolymer and ethylene - 5 parts by mass of ethylene-octene block copolymer of α-olefin block copolymer (manufactured by Dow Chemical Co., Ltd., trade name: Infuse D9100, MFR: 1, octene content: 12.8 mol%), mixed in the above ratio To make a resin composition, the resin composition is melt-kneaded at a set temperature of 200° C. using a 40 mmφ single-screw extruder equipped with a T-die, and using a rubber roller with a surface roughness Rzjis of 40 μm. Cast between casting rolls at °C, and quenched to form a film, thereby obtaining a sealing sheet with a thickness of 0.5 mm and embossed on both sides. Moreover, using the obtained sealing sheet, the solar cell module was produced as mentioned above. Table 1 shows the evaluation results.

Embodiment 2

[0168] In Example 1, except that the rubber roller whose surface roughness Rzjis was 40 μm was changed to a rubber roller whose surface roughness Rzjis was 15 μm, a solar cell sealing sheet and a solar cell module were produced in the same manner as in Example 1, Make an evaluation.

Embodiment 3

[0170] In Example 1, the resin composition was changed to 90 parts by mass of LLDPE (manufactured by Prime Polymer Co., Ltd., trade name: Evolue P SP9048, MFR: 4) and LLDPE (manufactured by Prime Polymer Co., Ltd., trade name: NEO-ZEX0234N , MFR: 2) Except having mixed 10 mass parts of resin compositions in the said ratio, it carried out similarly to Example 1, produced the sealing sheet for solar cells, and a solar cell module, and evaluated them.

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com