A pneumatically driven thermal insulation wax injection gun

A technology of air pressure drive and wax injection gun, which is applied in the direction of coating, liquid coating device on the surface, etc., which can solve the problems of increased production cost, easy wax solidification, waste of raw materials, etc., and achieve high connection and fastening degree and constant temperature No change, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

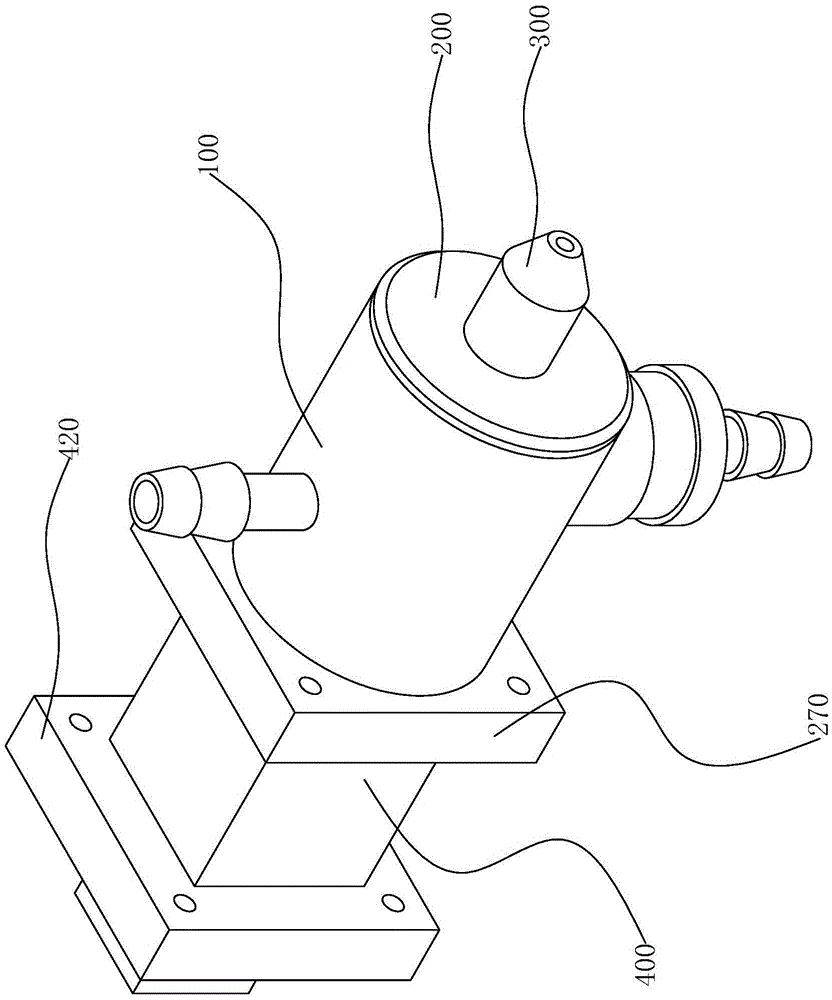

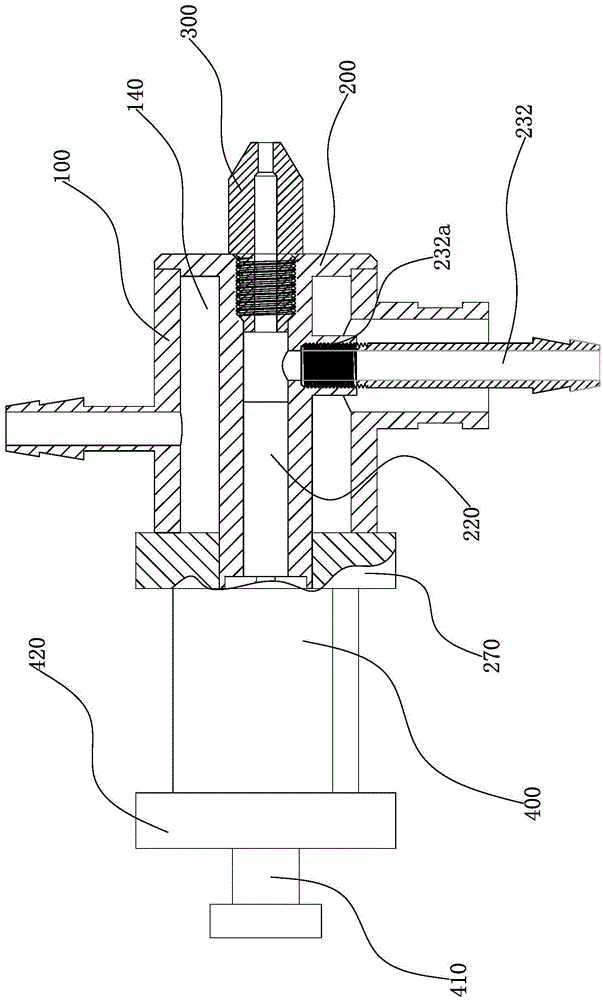

[0040] Such as Figure 1 to Figure 2 As shown, a pneumatically driven thermal insulation wax injection gun of the present invention includes a housing 100 , a gun body 200 , a gun head 300 , and a cylinder 400 .

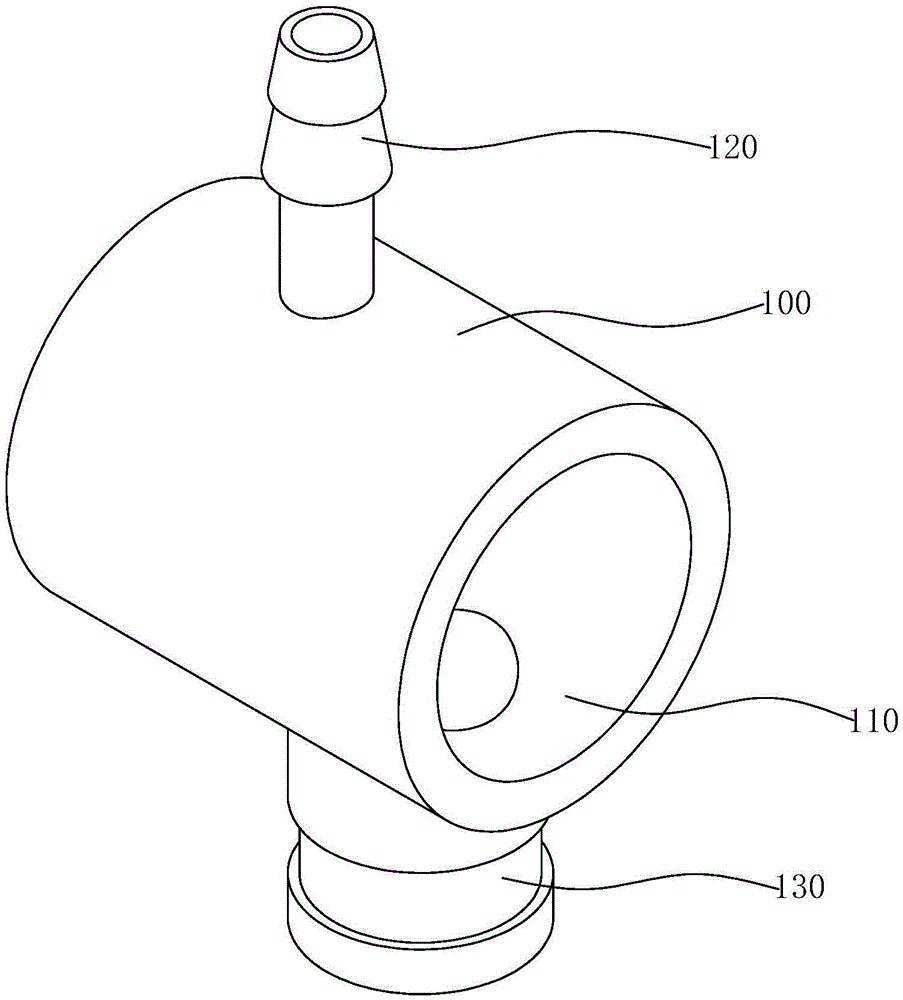

[0041] Such as image 3 , Figure 4 As shown, the casing 100 is long cylindrical and hollow inside to form a cylindrical accommodation chamber 110. The casing 100 is arranged horizontally, and a water inlet pipe 120 is vertically installed on the outer wall of the upper end of the casing 100. The water inlet pipe 120 is connected with the casing. The accommodating cavity 110 of the body 100 communicates, and a water outlet pipe 130 is installed vertically on the outer wall of the lower end of the housing 100. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com