A powdered oil shale retort furnace that uses the semi-coke produced by retort as fuel for heating

A technology of oil shale and carbonization furnace, which is applied in coking ovens, special forms of carbonization, and indirect heating carbonization, etc. It can solve the problems of carbon waste, affecting the oil and gas yield of stoves, and polluting the environment, so as to reduce emissions and avoid Explosion, the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and examples.

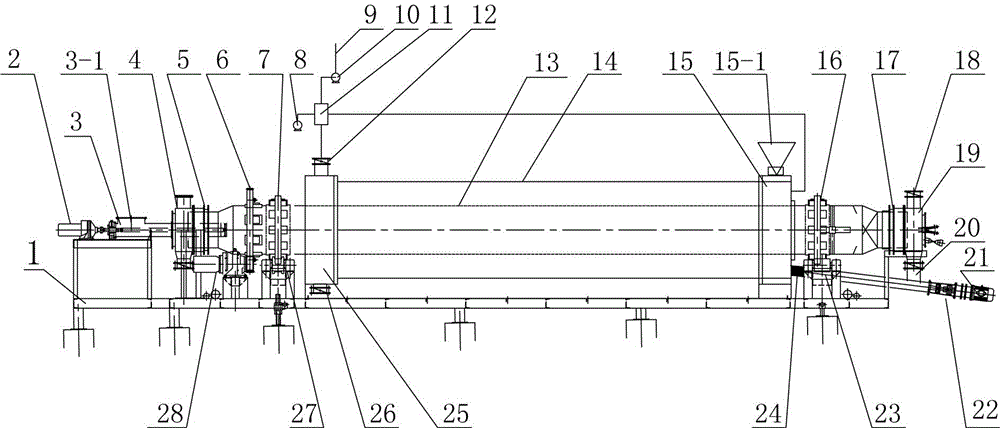

[0019] Such as figure 1 , The embodiment of the present invention comprises frame 1 and the front support roller 23 that is installed on the frame 1, rear support roller 27, rear rotary support body 25 and front rotary support body 15. Embodiments of the present invention also include a rotating inner cylinder 13 and a rotating outer cylinder 14 that are nested together and rotate synchronously. There is an annular semi-coke passage between the rotating inner cylinder 13 and the rotating outer cylinder 14. The front and rear ends of the cylinder 14 protrude, the front protruding end is seated on the front support roller 23 through the front raceway 16, and the rear protruding end is located on the rear support roller 27 through the rear raceway 7. The rear extension end is also equipped with a ring gear 6 , and the gear meshed with the ring gear 6 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com