Rapid tapping device

A kind of equipment and fast technology, applied in the direction of positioning device, thread cutting device, metal processing equipment, etc., can solve the problems of easy fatigue of operators and low production efficiency, and achieve the effect of improving tapping efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

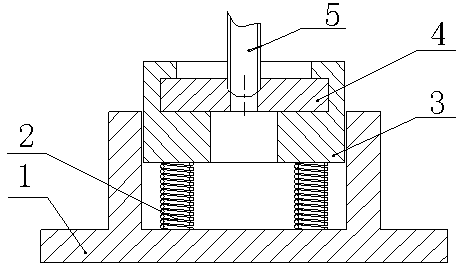

[0008] like figure 1 As shown, the lower end of the workpiece clamping device 3 is connected to the base 1 through four tension springs 2, and the square tubular guide rail formed by the base 1 limits the position of the workpiece clamping device 3 in the horizontal direction; the workpiece clamping device 3. It can move up or down in the vertical direction under the action of external force. The workpiece clamping device 3 is provided with a hole that matches the shape of the workpiece 4 to be processed. The workpiece clamping device 3 realizes the positioning of the workpiece to be processed by contacting the five surfaces of the workpiece 4 to be processed; the rotation of the tap 5 is controlled by the bench drill. Drive, by changing the rotation direction of the bench drill spindle to realize the rapid tapping and tap removal operation of the workpiece 4 to be processed; force. When the first piece is processed, the position of the equipment of the present invention rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com