Ink-return stamp and stamp pad for stamp

A technology of stamp and stamp pad, applied in the field of circular stamps, can solve the problems of unspecified circular stamps, etc., and achieve the effects of compact structure, realization of structure volume, and reduction of structure height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069]First of all, it needs to be pointed out that in the different embodiments described, the same components are represented by the same reference symbols or the same component names, wherein, the disclosure contained in the entire specification can be applied to components with the same reference symbols according to their meanings. same parts. In addition, positional information (eg, up, down, side, etc.) in the specification is for the directly described and illustrated drawings, and when the position changes, the positional information will apply to the new position according to its meaning. Furthermore, it should be pointed out that features can be derived from the figures shown.

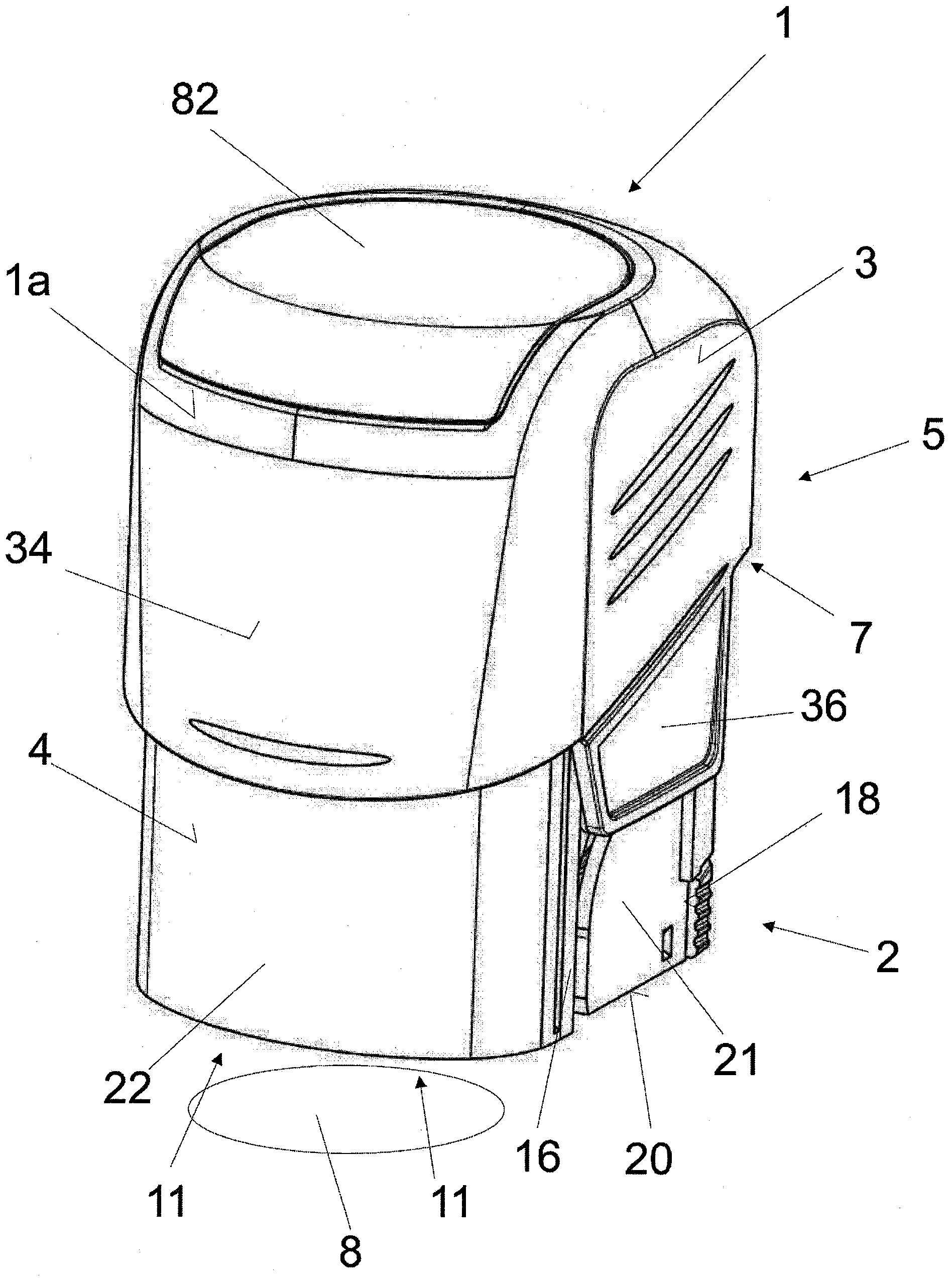

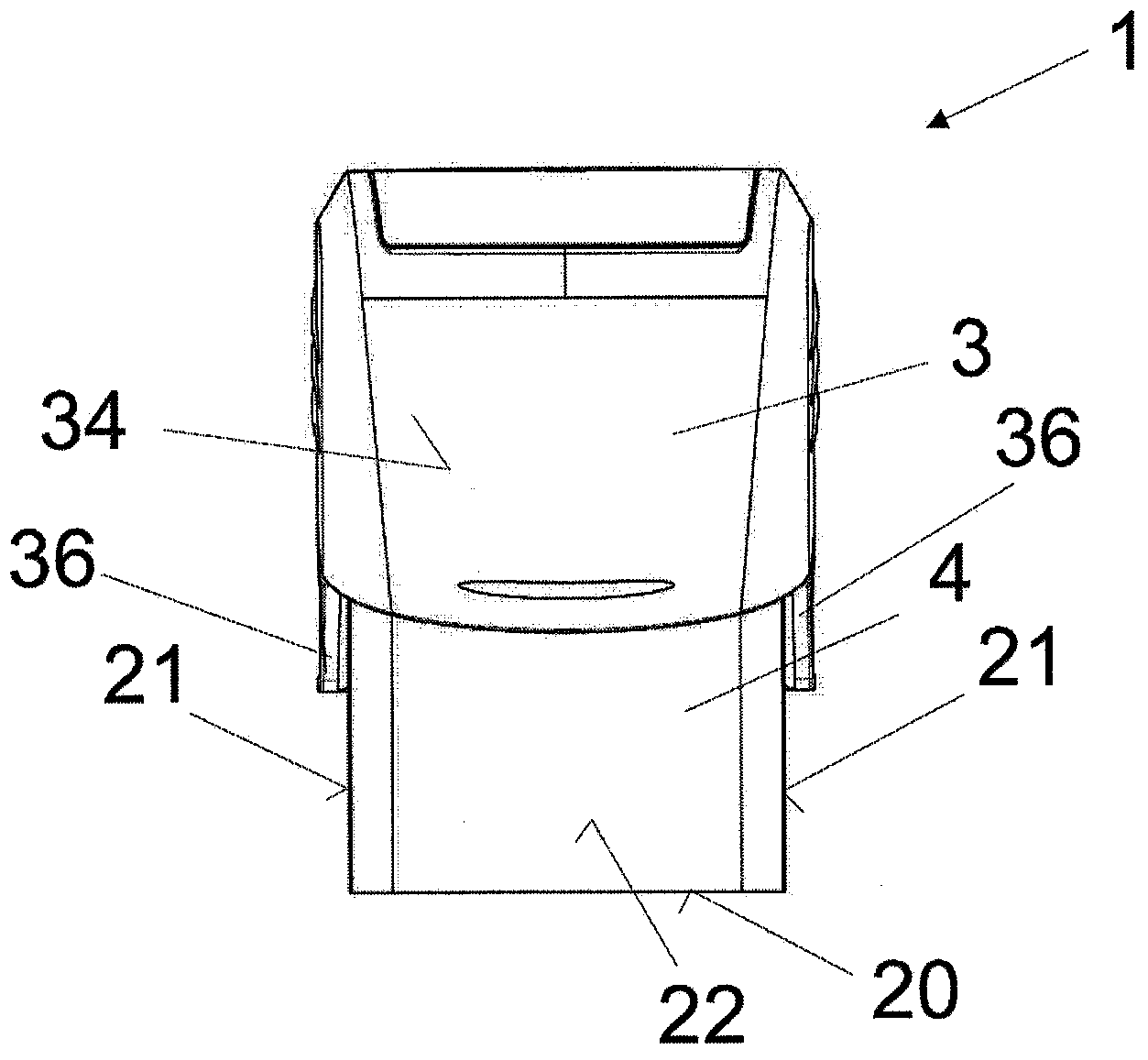

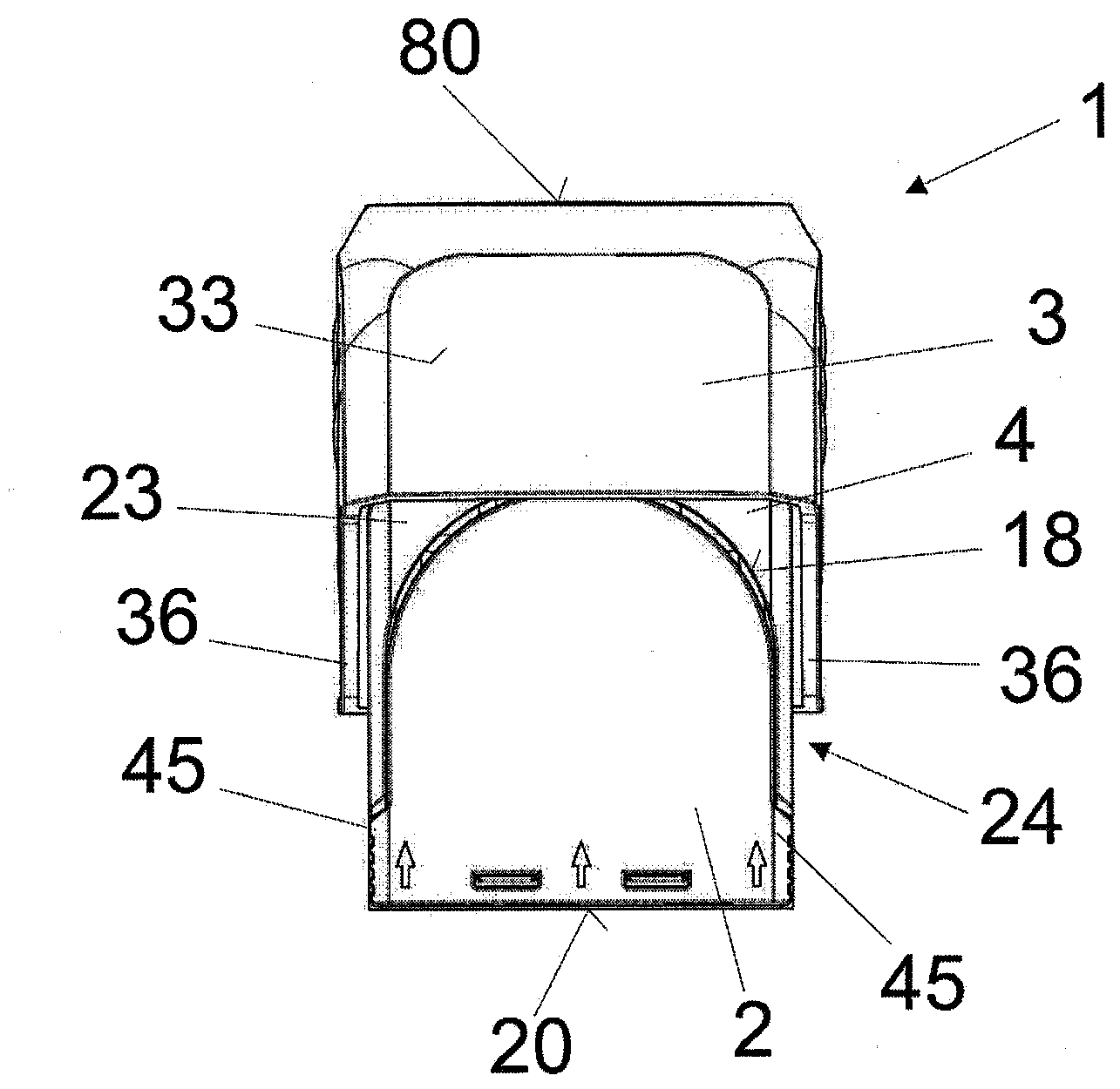

[0070] figure 1 To ### shows a ink-returning stamp 1 with an inserted stamp pad 2, in particular a so-called circular stamp 1a. The stamp 1 is composed of an upper part 3 and a lower part 4, which are constructed so that they can move towards each other, that is, in particular during the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com