Continuous corundum smelting flow furnace

A technology of corundum and discharge port, which is applied in the field of corundum smelting furnaces, can solve the problems of high temperature waste heat loss, high heat utilization efficiency, power grid impact, etc., and achieve the effects of convenient centralized smoke and dust removal, low production site requirements, and high electric heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

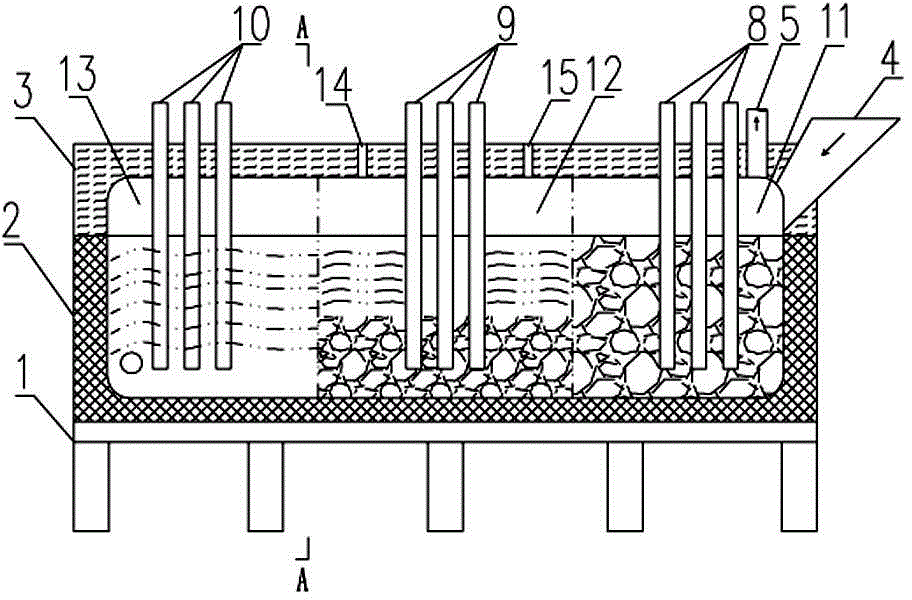

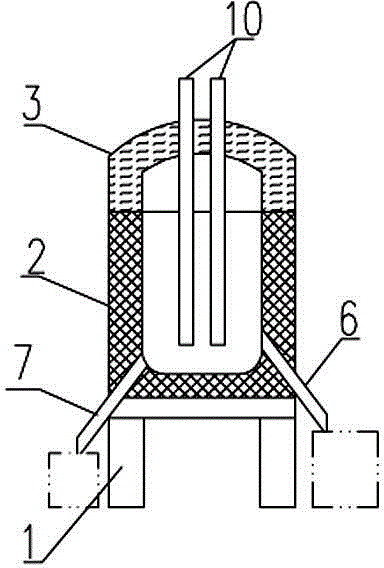

[0011] Such as figure 1 , 2 As shown, the continuous corundum smelting exile furnace according to the present invention includes an upper opening furnace body 2 arranged on a support platform 1, a furnace cover 3 which is sealed and buckled on the upper opening furnace body 2, and is arranged in a furnace cavity The heating electrode inside and the feed port 4, discharge port and smoke exhaust port 5 communicated with the furnace cavity; the feed port 4 is arranged on the right side wall of the furnace cover 3, and the discharge ports are respectively The corundum melt discharge port and the ferrosilicon melt discharge port provided on the opposite side walls of the left end of the furnace body 2, the height of the corundum melt discharge port is greater than the height of the ferrosilicon melt discharge port, and the corundum melt The liquid flow outlet and the ferrosilicon melt outlet are respectively provided with guide pipes 6 and 7 obliquely downward; the smoke exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com