Nylon mesh reinforced concrete structure light slab inner wall and its preparation equipment, preparation and installation method

A technology of mesh-reinforced concrete and nylon mesh, which is applied to walls, manufacturing tools, building components, etc., can solve the problems of large space occupation of the production site, insufficient strength, and long installation period, so as to improve the level of employee welfare and improve the production site The effect of low requirements and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

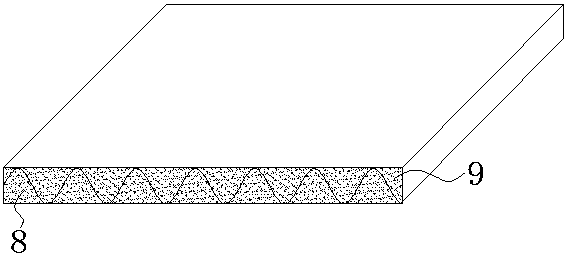

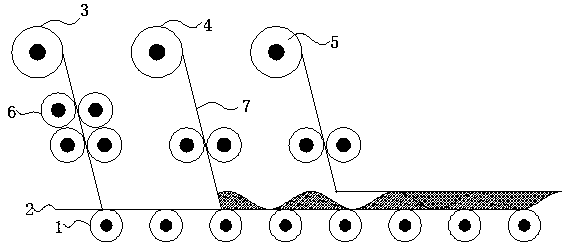

[0020] Embodiment 1: as figure 1 Shown, the light-duty large slab interior wall of nylon mesh reinforced concrete structure, it comprises as the double-layer nylon net 7 of wall inside and outside, slurry and: one layer of arc-wave lining that is laid at intervals between the inside and outside of wall, described slurry The material includes aggregate and adhesive, and the arc wave lining includes the arc-shaped negative insulation strip 8 with the peak facing upward, the double-layer nylon mesh as the isolation layer laid on the surface of the arc-shaped negative insulation strip and the double-layer nylon mesh laid on the surface as the isolation layer The crest on the double-layer nylon net faces downwards the arc-shaped sunny side insulation strip 9.

[0021] The inner wall of the present invention uses double-layer nylon mesh as reinforcement, fine stone and sand as aggregate, and cement as adhesive, and is mixed and stirred to make slurry. In order to achieve the strengt...

Embodiment 2

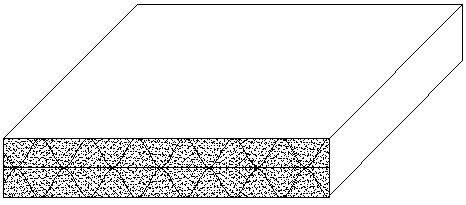

[0029] Embodiment 2: The present invention can adopt single-wave and double-wave boards according to different indoor positions, and use multi-wave layer boards under the windows of the outer walls. The single wave, double wave and multiple waves here refer to the number of layers of the arc wave lining. The above description is only an example for a single-wave slab. The production equipment for the light-weight large slab inner wall of the nylon mesh reinforced concrete structure of the present invention can also be provided with a fourth roller, a fifth roller, and a corresponding spray roller mechanism. The corresponding nylon mesh reinforcement The preparation method of the production equipment for the inner wall of the light-duty large slab of the concrete structure is also adjusted to make the double wave plate. The double wave plate structure is as follows figure 2 As shown, the double-wave board has 5 layers of double-layer nylon mesh, two yin and yang insulation str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com