Method for preparing solder balls with uniform ball diameter and high degree of sphericity

A sphericity and tin ball technology, applied in the field of tin ball preparation, can solve the problems of general sphericity, waste of resources, increased production cost, etc., and achieve the effect of meeting packaging manufacturing needs, low production site requirements, and low tower equipment height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

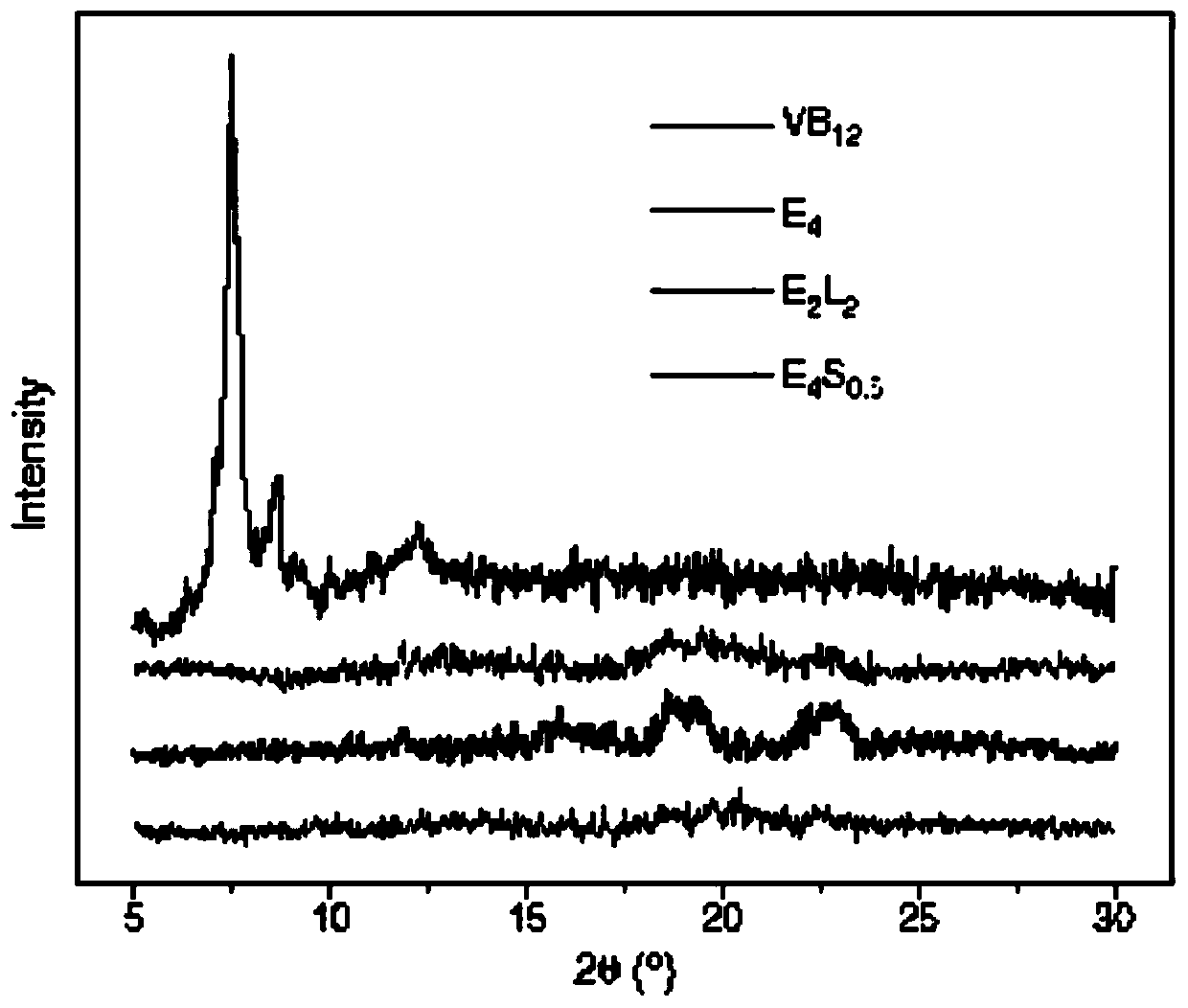

[0017] The present invention is described below in conjunction with accompanying drawing.

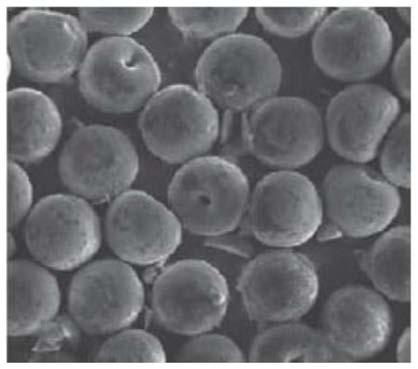

[0018] A method for preparing tin balls with uniform ball diameter and good sphericity according to the present invention comprises the following steps:

[0019] ① Preparation of precursor solution: Weigh 96.5~96.8g of tin ingot, 3g of silver particles, and 0.2~0.5g of copper particles, put them into a sealed quartz crucible, place them in a muffle furnace, and heat them at a high temperature of 1100 degrees for half an hour or so, until it is completely melted; cool down the completely melted alloy solution to 260 degrees, and then transfer it to a high-temperature-resistant autoclave;

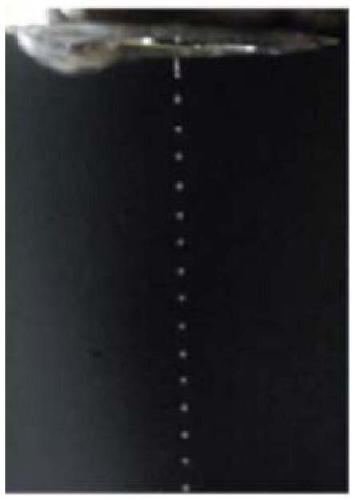

[0020] ②Microfluidic spray freeze drying: first set the frequency of the ultrasonic oscilloscope to 6~20KHZ and the amplitude to 0~20, start the compressor to circulate absolute ethanol, and wait until the temperature drops to zero; set the flow rate of the precursor liquid to 1~10m / s and the resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com