Machine tool

A machine tool and tool technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, mechanical equipment, etc., can solve problems such as vibration, affecting the service life of the machine, and uncomfortable users, so as to reduce the risk of overload and reduce overload. Risk, the effect of reducing the risk of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

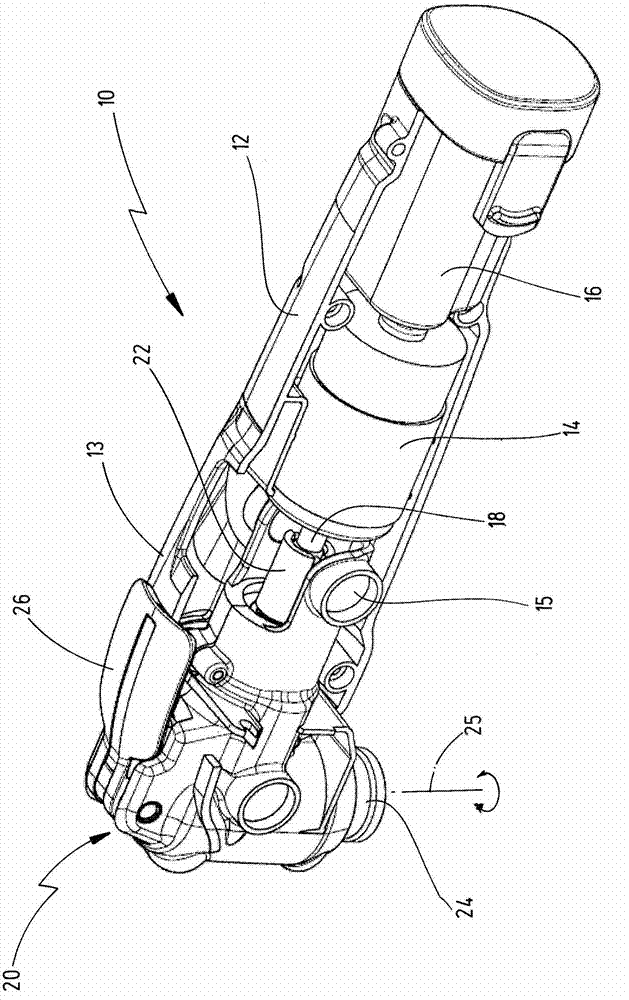

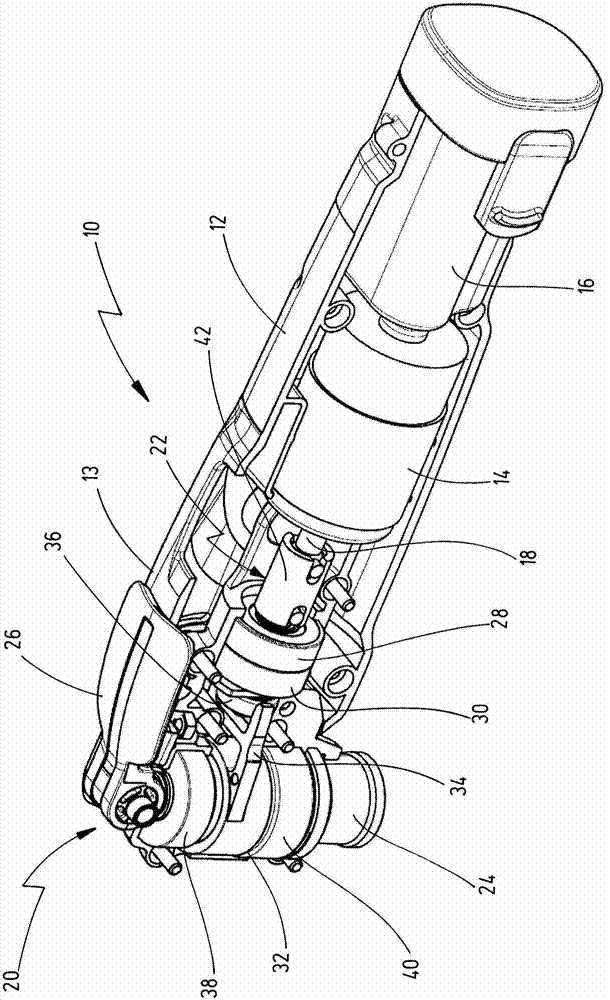

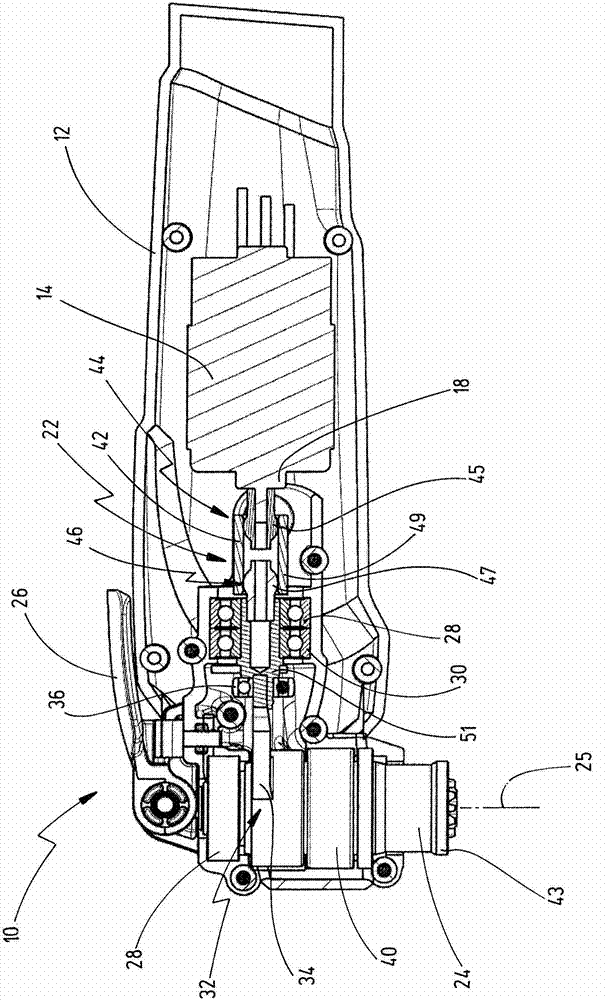

[0042] Figure 1-3 A first embodiment of the power tool according to the invention is shown, generally designated 10 . It is an oscillatingly driven power tool 10 having a motor housing 12 in which a drive motor 14 is accommodated and a gear housing 13 in which a tool drive shaft 24 is accommodated. The rotational movement of the motor shaft 18 is converted via the coupling device 22 and the corresponding coupling gear 20 into an oscillating drive movement of the tool drive shaft 24 about its longitudinal axis 25 .

[0043] On the outer end of the tool drive shaft 24 (the outer end protruding outward from the housing 12) a tool receiving device 43 is provided ( image 3 ), on which a corresponding tool, such as a grinding tool, a cutting tool or a sawing tool, can be fixed by means of a quick clamping device (not shown) with the aid of a clamping rod 26 . The tool drive shaft 24 is supported on the housing 12 by means of two bearings 38, 40 ( figure 2 and 3 ).

[0044]Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com