Method for driving print unit

A printing unit and driving motor technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of power design asymmetry, motor or regulator overload, and other problems, so as to achieve full and good operation and avoid over The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

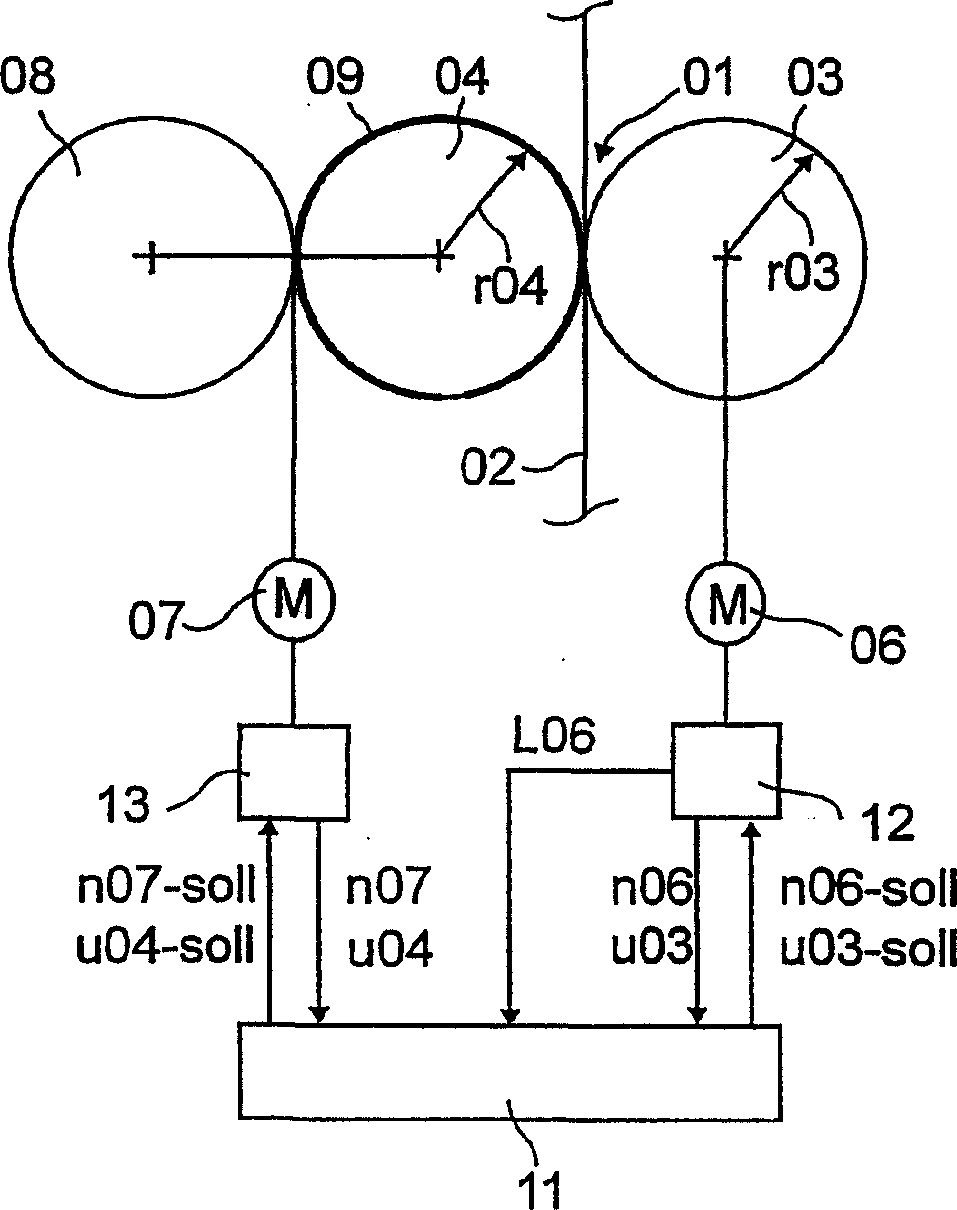

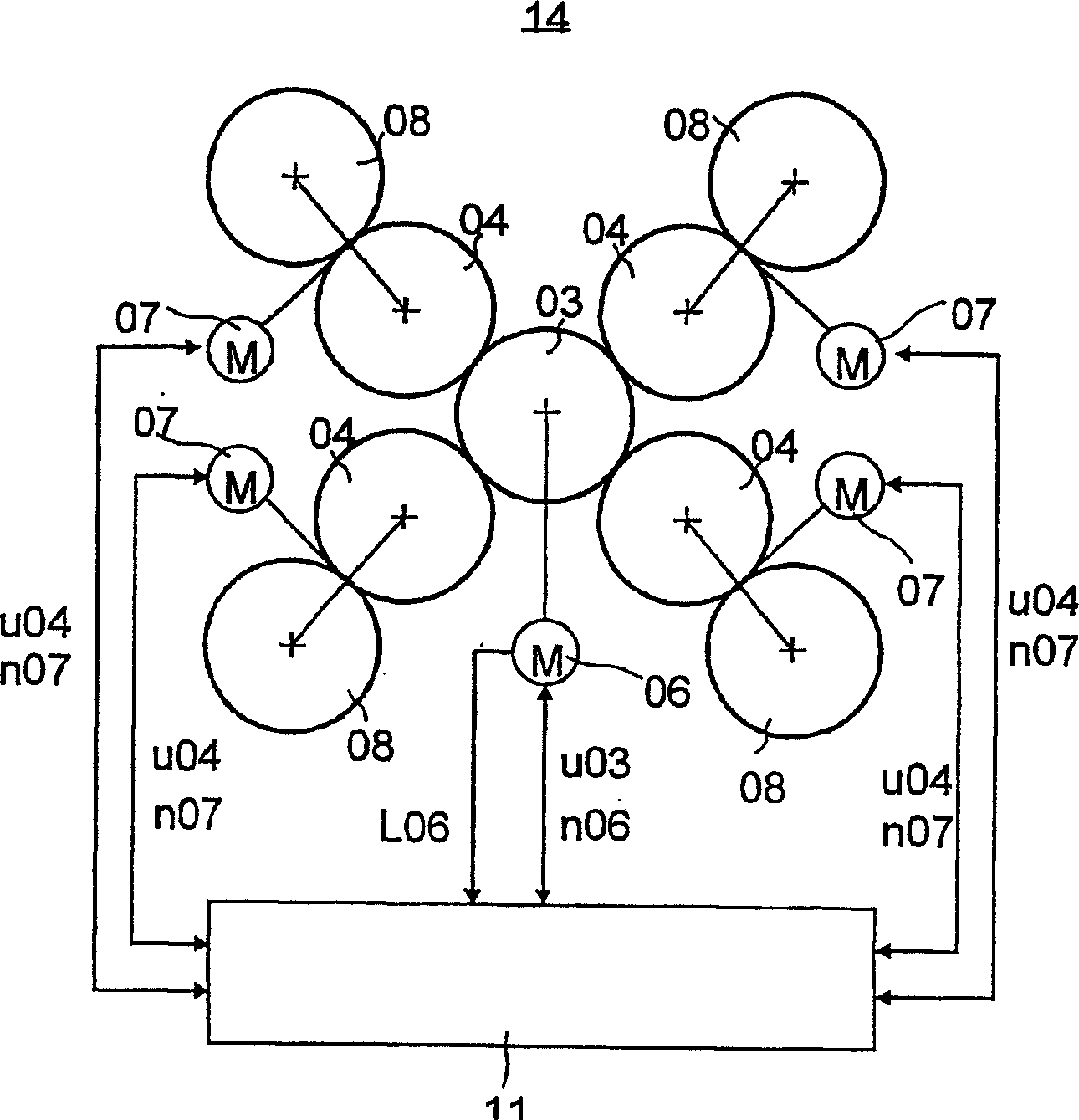

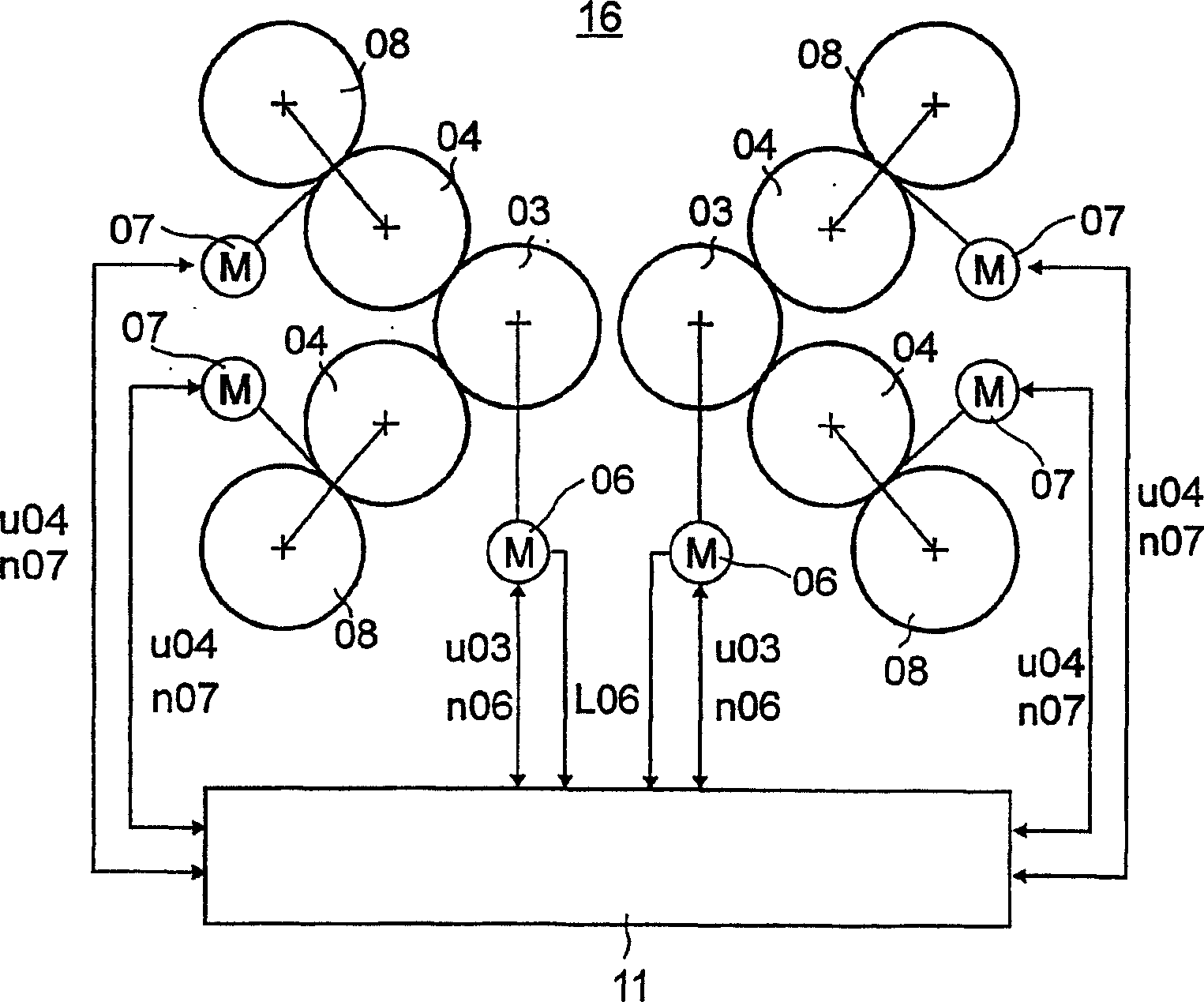

[0022] The rotary printing press has a printing point 01 with two rollers on a belt, such as a printing material belt, especially a paper belt 02, which are press-fitted on each other. The roller is, for example, without a roller and uses its mutually rolling shell surfaces to form a friction transmission device. The first cylinder is an impression cylinder 03, such as a steel cylinder and directly or indirectly through a drive motor 06, but independent of the second cylinder, such as a transfer cylinder 04 or a copper-zinc plate cylinder for high-pressure or flexographic printing. driven.

[0023] For example, the second roller as the transfer roller 04 is also directly or indirectly driven, for example, by a transmission device not shown in the figure, such as a gear, a toothed belt, or a friction transmission device using the second drive motor 07. The transfer cylinder 04 can be driven separately or together with a third cylinder cooperating with the transfer cylinder, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com