Scroll saw driven by electromagnets

A technology of electromagnet and jig saw, applied in the field of jig saw, can solve the problems of large lateral component force, power consumption and wear, etc., and achieve the effects of low cost, extended service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

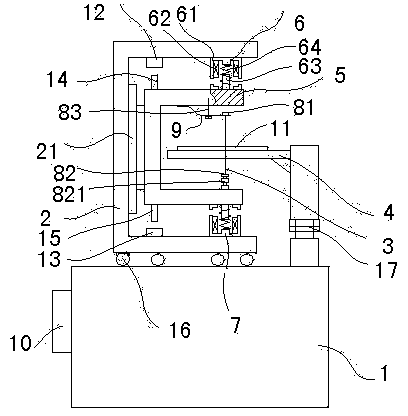

Embodiment 1

[0026] Embodiment 1: as figure 1 As shown, a jigsaw driven by an electromagnet includes a base 1, a frame 2, a saw blade 3 and a worktable 4, the workbench 4 is connected to the base 1, the frame 2 is a U-shaped structure, and the frame 2 is movable placed on the base 1; the middle part of the inside of the frame 2 is fixed with a guide rail 21 along the up and down direction, and the guide rail 21 is equipped with a bow-shaped saw frame 5; the upper port part of the inside of the frame 2 is connected with an upper electromagnet 6, The lower port position inside the frame 2 is connected with a lower electromagnet 7, the upper electromagnet 6 and the lower electromagnet 7 are each composed of a yoke 61, a solenoid 62 and an armature core 63, and the outer bottom of the yoke 61 is connected to the frame 2 Fixed connection, one end of the armature core 63 is fixedly connected with the outside of the saw frame 5, and the cylindrical coil spring 64 is covered with a gap between th...

Embodiment 2

[0033] Embodiment 2: The solenoids of the upper electromagnet 6 and the lower electromagnet conduct in turn, and the directions of their active forces are opposite, and all the other structures are the same as in Embodiment 1.

Embodiment 3

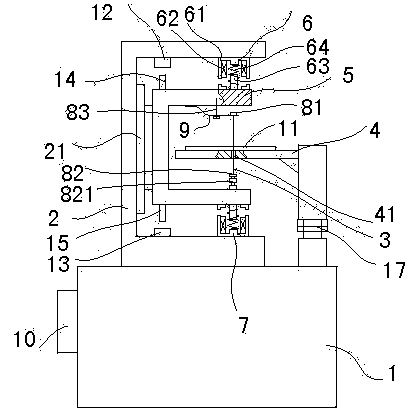

[0034] Embodiment 3: The frame and the machine base are fixedly connected, the corresponding parts of the workbench and the saw blade have a through hole 41 that can pass through the saw blade, and the rest of the structure is the same as that of Embodiment 1, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com