Arch gantry crane

A gantry crane and arched technology, which is applied in the field of gantry cranes and arched gantry cranes, can solve problems such as inability to effectively solve resistance or inertial force, unsafe lifting operation, and limited lifting height, so as to achieve stable lifting and lower The construction cost and the effect of small lifting swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

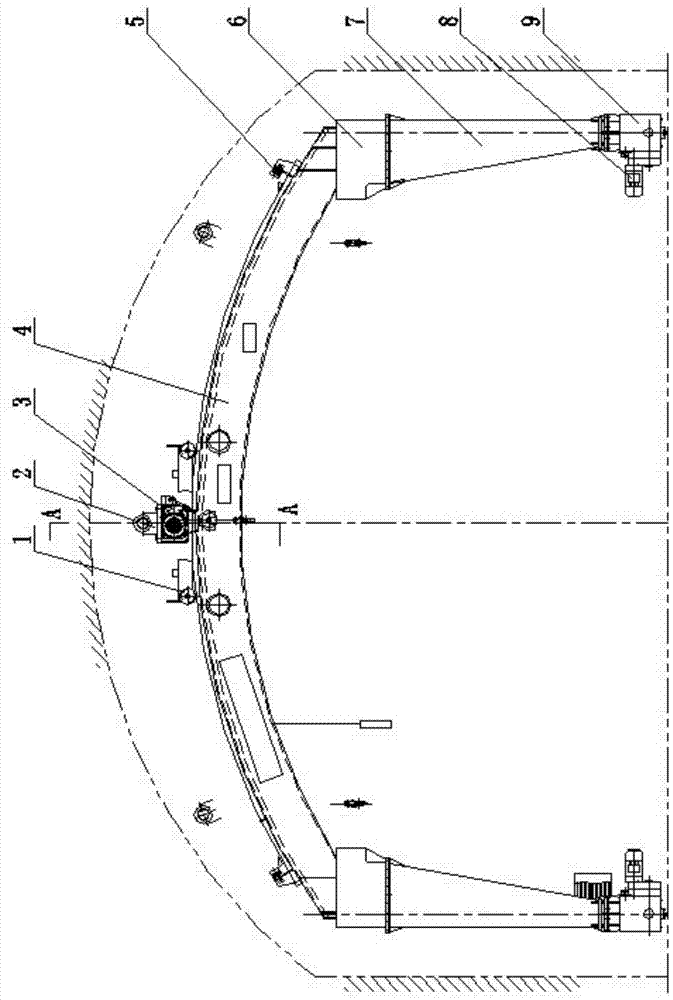

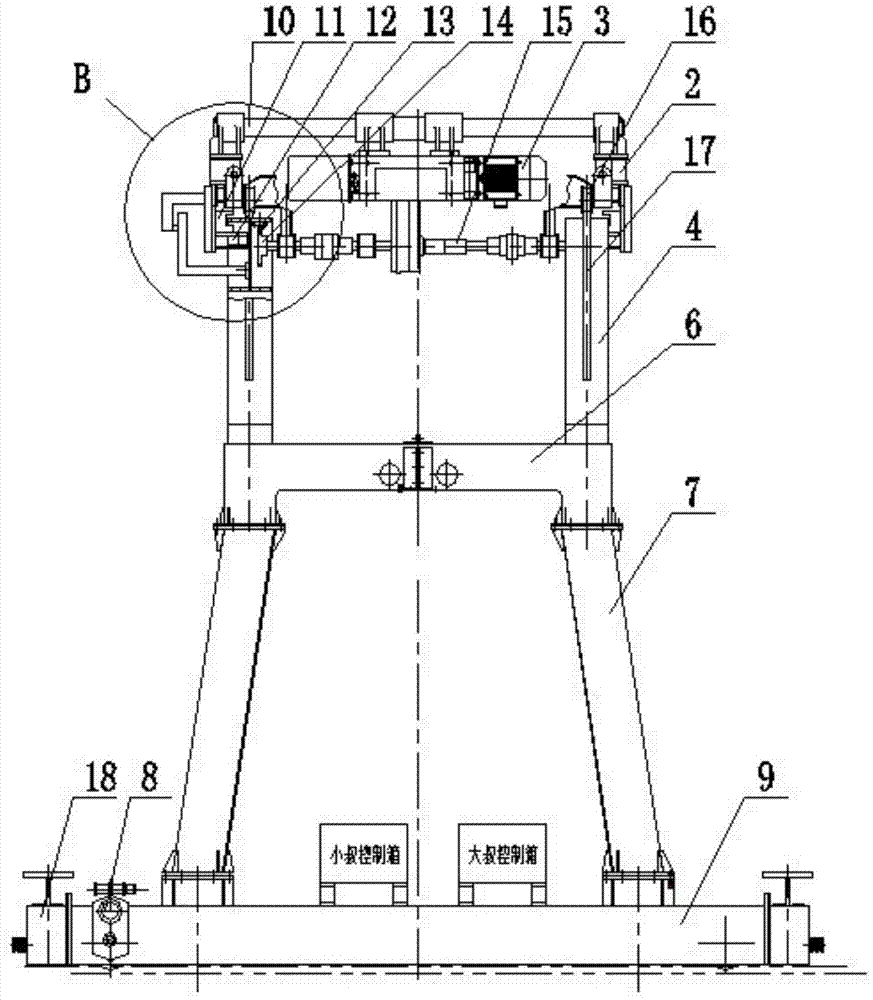

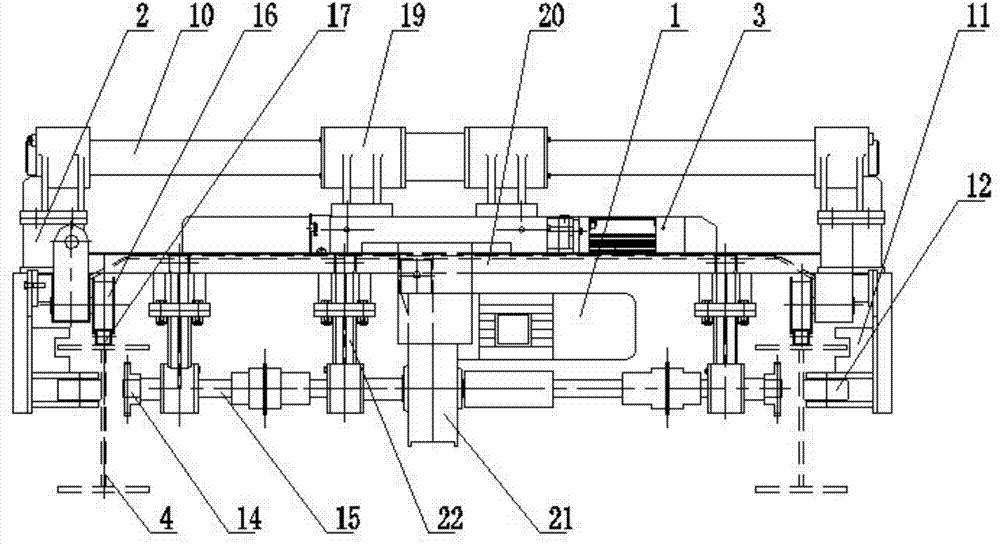

[0026] An arched gantry crane, the lifting bridge of which is an arched double main girder type gantry structure, including a lower beam 9, outriggers 7, an upper beam 6, an arched main girder 4, an electric hoist 3, and a running trolley 2. The cross beams are two horizontal beams walking on the ground rails, the cart motor and its reducer 8 are installed on the lower cross beams, and the manual brakes 18 are also installed on the lower cross beams. The upper leg is fixed with an upper beam on the upper end of the leg. The main beam is an arched main beam. There is a running trolley, which straddles the arched main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com