A method for metal hydrothermal reduction of glycerin to produce propylene glycol

A technology of propylene glycol and glycerin, which is applied in the field of environmental chemical industry to achieve the effects of convenient operation, fast reaction rate and mild reaction temperature conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

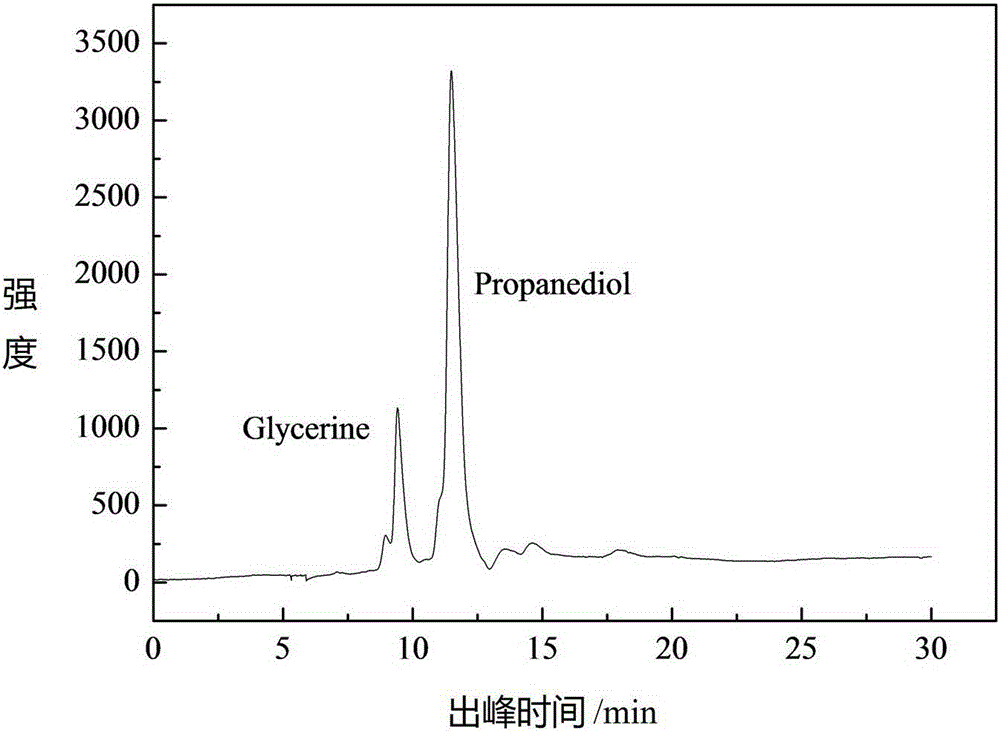

Embodiment 1

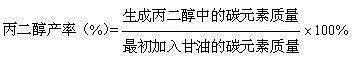

[0023] Add 0.07g glycerol, 10mmol metal Ni, and a certain amount of Fe into the reactor, wherein Fe is determined by Fe / Ni molar ratio of 1 / 2, 3 / 4, 1 / 1, 4 / 3 and 2 / 1 respectively , under the conditions of reaction temperature of 280°C and reaction time of 150 min, hydrothermal reduction reaction occurs, and propylene glycol is obtained by separating the product. Then adjust the reaction temperature to 230°C, 250°C, 280°C and 300°C respectively, 0.07g of glycerin, 10mmol of Fe and Ni, and a reaction time of 120min to prepare propylene glycol; finally adjust the reaction time to 60min, 90min, 120min, and 150min and 180 min, 0.07 g of glycerin, 10 mmol of both Fe and Ni, and a reaction temperature of 250° C. to prepare propylene glycol. When the amount of glycerol added is 0.07g, the amount of Fe and Ni added is 10mmol, the reaction temperature is 250°C, and the reaction time is 120min, the yield of propylene glycol reaches 53.14%, and the conversion rate of glycerol reaches 79.25...

Embodiment 2

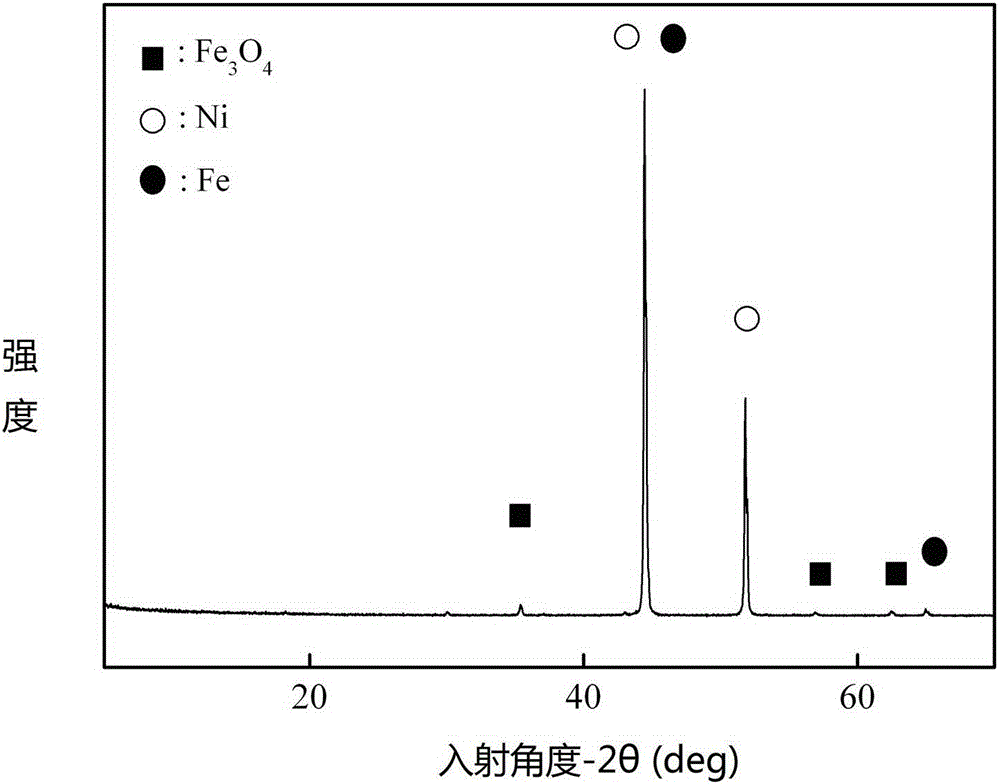

[0025] Under the joint action of Fe-Ni, the solid residue collected after the reaction in Example 1 was filtered and rinsed with deionized water, and dried in an oven at 70° C. for testing. D / MAX2550 type X-ray diffractometer is used for detection, the 2θ angle range of X-ray diffraction is 5-70°, and the rotation angle rate is 10° / min. The analysis results show that the attached figure 2 As shown, Fe reacts with Fe 2 o 3 Form exists, and Ni does not change, and in conjunction with embodiment 1, proves that in this reaction Fe is used as reducing agent, and Ni is used as catalyst, and this reaction does not need to provide the reason of external hydrogen source just.

Embodiment 3

[0027] Add 0.07g of glycerin, Cu and Ni into the reactor with the same dosage, the dosage is 1mmol, 3mmol, 5mmol, 10mmol and 15mmol in sequence, and the reaction temperature is 280℃, and the reaction time is 150min. Hydrothermal reduction reaction to obtain propylene glycol by isolating the product. Then adjust the reaction temperature to 230°C, 250°C, 280°C and 300°C respectively, 0.07g of glycerol, 10mmol of Cu and Ni, and 120min of reaction time to prepare propylene glycol; finally adjust the reaction time to 60min, 90min, 120min, and 150min respectively and 180 min, 0.07 g of glycerin, 10 mmol of both Cu and Ni, and a reaction temperature of 250° C. to prepare propylene glycol. When the addition amount of glycerol is 0.07g, the addition amount of Cu and Ni is 10mmol, the reaction temperature is 250℃, and the reaction time is 120min, the yield of propylene glycol reaches 46.61%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com