A multifunctional soil conditioner

A soil improver and multi-functional technology, applied in the direction of soil conditioning materials, applications, organic fertilizers, etc., can solve the problems of lack of research and development of special soil improvers, neglect of regional differences in improved soil, unsuitable for mechanized application, etc., to achieve enhanced fertilizer and water penetration force, improve the microbial environment, and promote the effect of soil microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

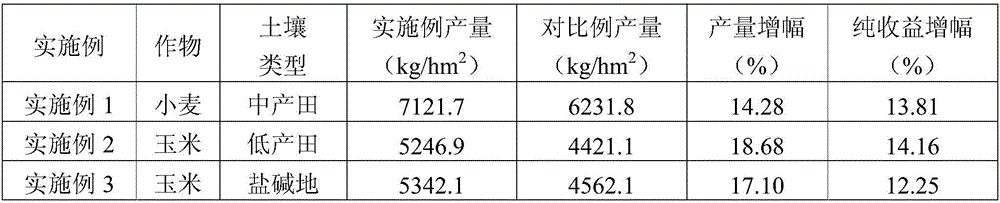

Examples

Embodiment 1

[0043] A soil improver, with organic matrix, inorganic matrix, nutrient elements, and composite resin as basic raw materials, the mass parts of each component are: 55 parts of weathered coal, 25 parts of bentonite, 10 parts of composite resin, 3 parts of monoammonium phosphate, Potassium sulfate 7 parts.

[0044] The preparation method is as follows:

[0045] (1) Grinding the weathered coal and furfural slag to a particle diameter of 0.1-0.3 mm. 250 parts by weight of water, 30 parts by weight of furfural slag, 70 parts by weight of weathered coal, and 6 parts by weight of acrylic acid (neutralization degree 60%) were sequentially added into the reactor, and stirred evenly. Under nitrogen protection, 0.2 parts by mass of methylenebisacrylamide and 2 parts by mass of ammonium persulfate were added. After reacting at 60-70°C for 3 hours, the product is composite resin.

[0046] (2) Dry the organic matrix, inorganic matrix, nutritional elements, and composite resin until the w...

Embodiment 2

[0049] A soil improver, with organic matrix, inorganic matrix, nutrient elements, and composite resin as basic raw materials, the mass parts of each component are: 65 parts of weathered coal, 15 parts of bentonite, 10 parts of composite resin, 4 parts of monoammonium phosphate, Potassium sulfate 6 parts.

[0050] The preparation method is as follows:

[0051] (1) Grinding the weathered coal and furfural slag to a particle diameter of 0.1-0.3 mm. 300 parts by mass of water, 50 parts by mass of furfural slag, 90 parts by mass of weathered coal, and 10 parts by mass of acrylic acid (neutralization degree 60%) were sequentially added into the reactor, and stirred evenly. Under nitrogen protection, 0.4 parts by mass of methylenebisacrylamide and 4 parts by mass of ammonium persulfate were added. After reacting at 70°C for 6 hours, the product is composite resin.

[0052] (2) Dry the organic matrix, inorganic matrix, nutritional elements, and composite resin until the water conte...

Embodiment 3

[0055] A soil improver, with organic matrix, inorganic matrix, nutrient elements, and composite resin as basic raw materials, the mass parts of each component are: 55 parts of weathered coal, 15 parts of bentonite, 20 parts of composite resin, 6 parts of monoammonium phosphate, Potassium sulfate 4 parts.

[0056] The preparation method is as follows:

[0057] (1) Grinding the weathered coal and furfural slag to a particle diameter of 0.1-0.3 mm. 250 parts by mass of water, 40 parts by mass of furfural slag, 60 parts by mass of weathered coal, and 8 parts by mass of acrylic acid (neutralization degree 60%) were sequentially added into the reactor, and stirred evenly. Under nitrogen protection, 0.3 parts by mass of methylenebisacrylamide and 3 parts by mass of ammonium persulfate were added. After reacting at 60-70°C for 5 hours, the product is composite resin.

[0058] (2) Dry the organic matrix, inorganic matrix, nutritional elements, and composite resin until the water con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com