Hydraulic power type pulp flowing box

A technology of convergent flow and turbulent flow generator, applied in the field of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

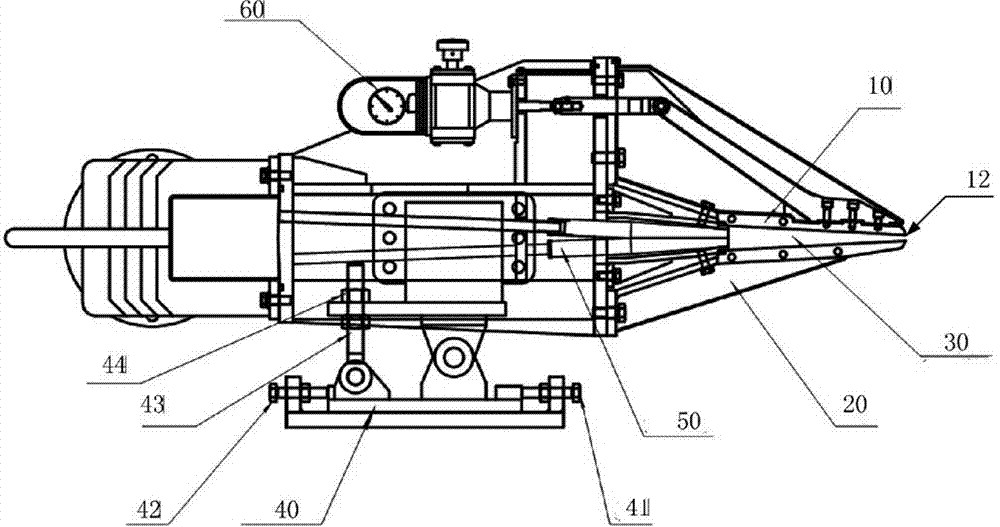

[0022] Wherein, the turbulence generator 50, the local fine-tuning mechanism 60, the upper lip 10 and the lower lip 20 are arranged on the adjustable base 40; the adjustable base 40 can adjust the headbox to move up and down and back and forth. refer to figure 1 , the adjustable base 40 is equipped with a first bolt 41, a second bolt 42, a screw rod 43 and a nut 44, and adjusting the first bolt 41 and the second bolt 42 can make the headbox move back and forth; adjust the vertical screw rod 43 Nut 44 can make the headbox move up and down.

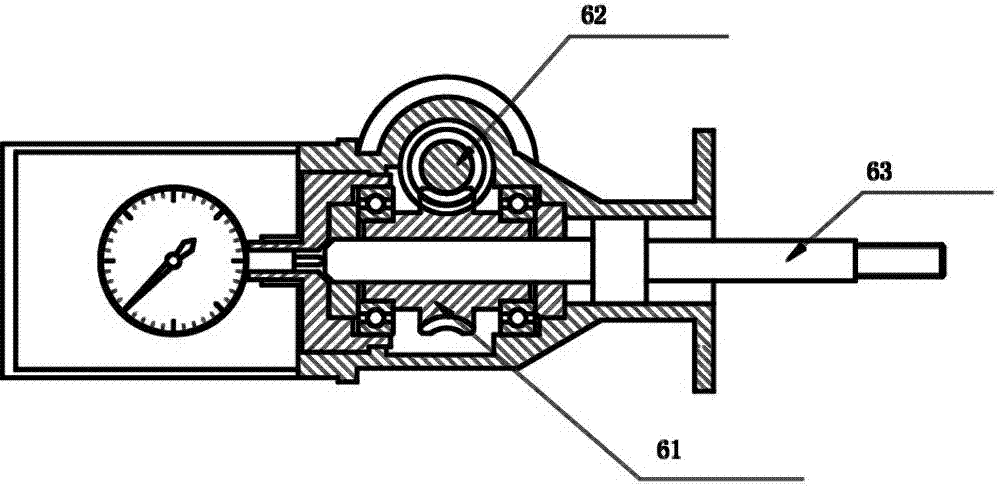

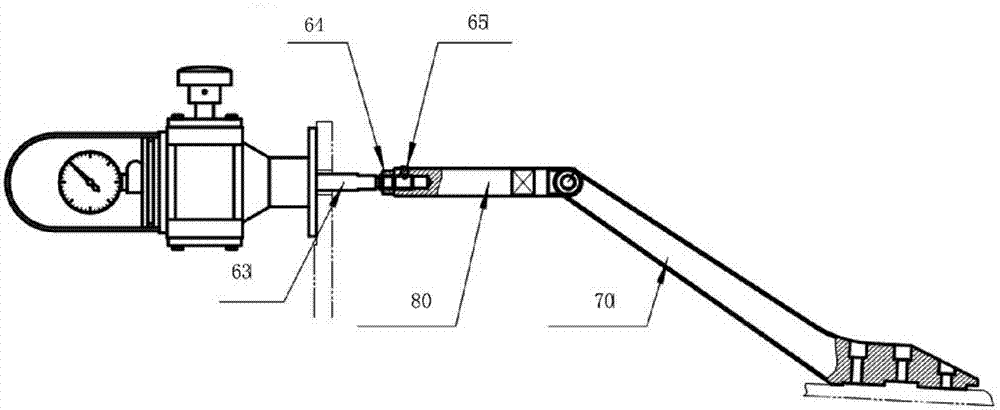

[0023] The local fine-tuning mechanism 60 is connected to the upper lip 10 .

[0024] A converging channel 30 is formed between the upper lip 10 and the lower lip 20 .

[0025] The turbulence generator 50 receives the converging channel 30 behind. refer to figure 1 , the turbulent flow generator includes at least two groups of stainless steel tube bundles, the inlet end of each stainless steel tube bundle is a circular port, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com