Mine film type high and low voltage conversion device

A high-low pressure conversion, thin-film technology, which is used in mining equipment, mine/tunnel ventilation, and earth-moving drilling, etc., can solve the problems of large cooling loss of pressure-reducing devices, reduce operating energy consumption, reduce cooling loss, and avoid The effect of direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

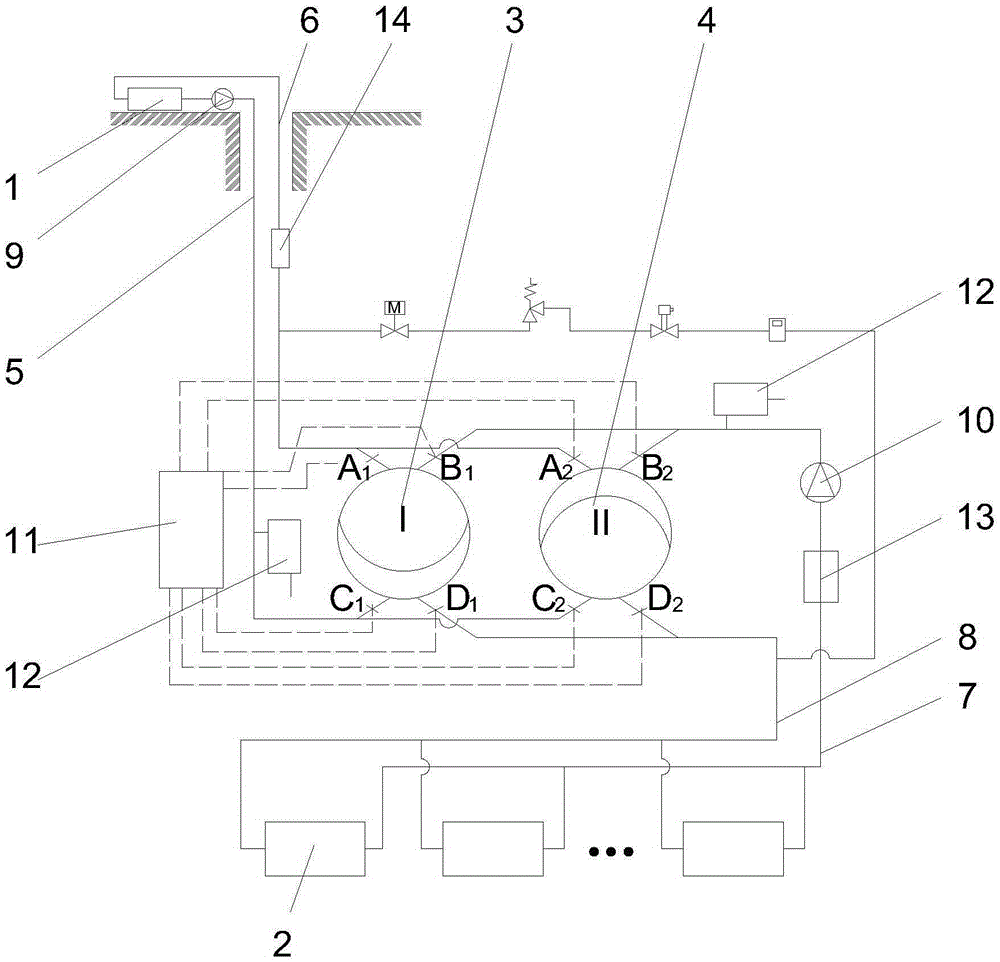

[0022] As shown in the figure, the thin-film type high-low pressure conversion device for mining in this embodiment includes a refrigeration station 1 arranged outside the mine and a radiator 2 arranged in the mine. The device 2 absorbs the heat in the local area of the mine and enters the circulating water. It also includes the container I3 and the container II4 arranged in the mine. The elastic film I is arranged in the container I3, and the elastic film I separates the container I3 into a cold water side and a hot water side. side, the cold water side of the container I3 communicates with the water outlet 5 of the refrigeration station 1 and the water inlet 8 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com