Planetary gear annular gear structure for brake

A technology of planetary gears and ring gears, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of slow braking speed and complex structure, and achieve the effect of convenient maintenance, overcoming complex structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

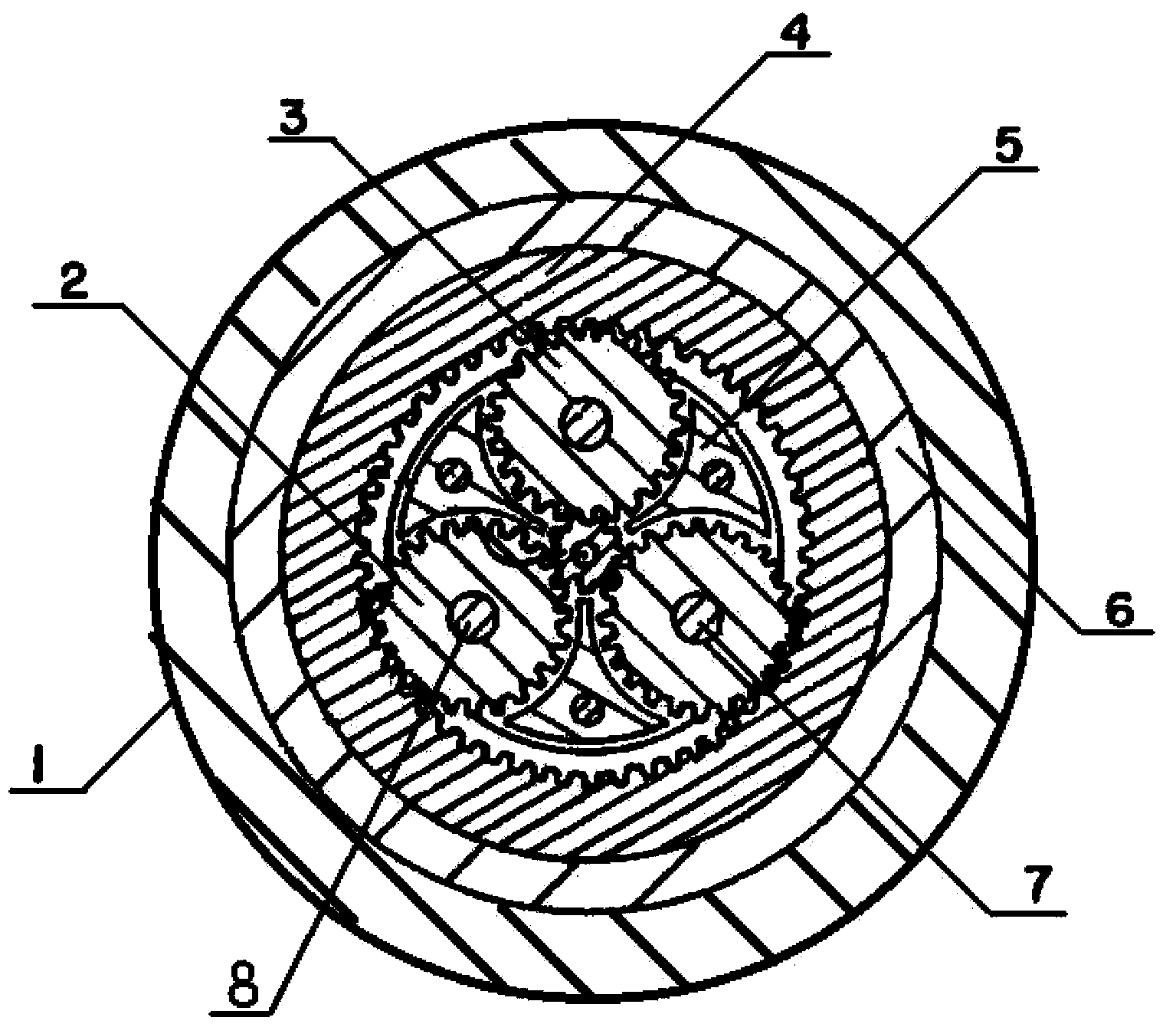

[0009] The planetary gear ring gear structure has a ring gear body (1), a caliper body (6) is arranged on the inner circle of the ring gear body (1), and a central gear (2) is arranged in the inner cavity of the caliper body (6). A planetary gear (3) is engaged on the central gear (2), and the central gear (2) and the planetary gear (3) have a central gear shaft (8) and a planetary gear shaft (7) to install and fix respectively, and the central gear (2) ) and the teeth of the planetary gear (3) are hinged with a ring gear (4), and the ring gear (4) is riveted on the caliper body (6) by uniformly distributed ring positioning keys (5).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap