Leaking stoppage device

A body and movable baffle technology, applied in the field of plugging devices, can solve the problems of high manufacturing cost, long plugging time, complex structure, etc., and achieve the effects of low cost, rapid plugging, and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings:

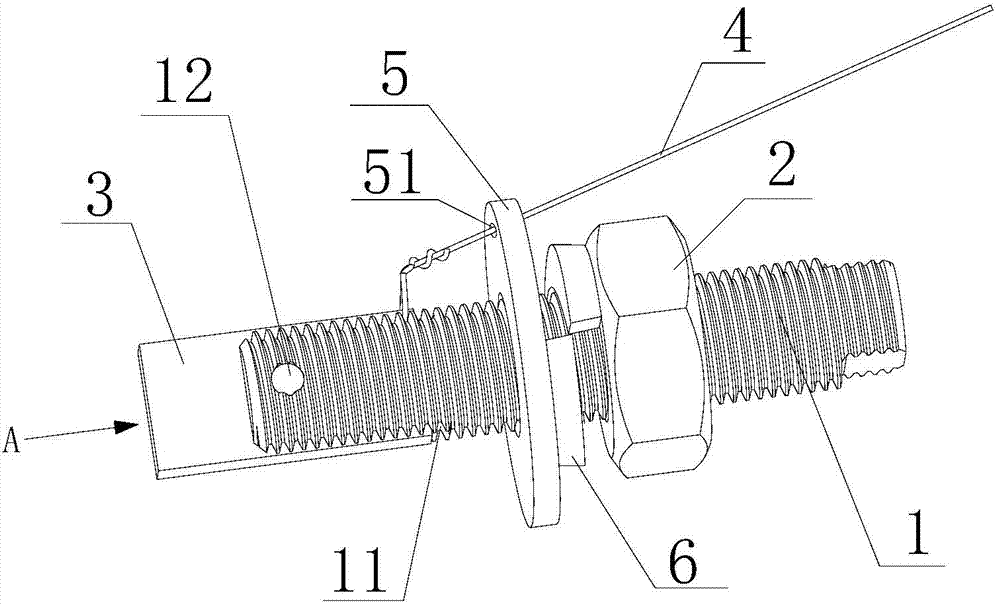

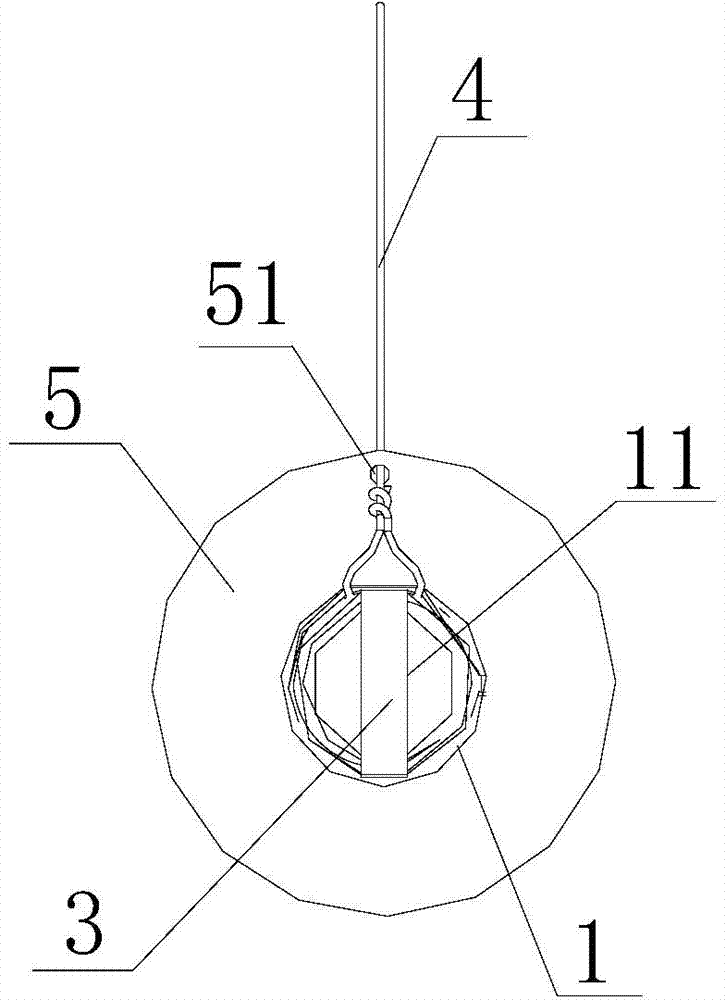

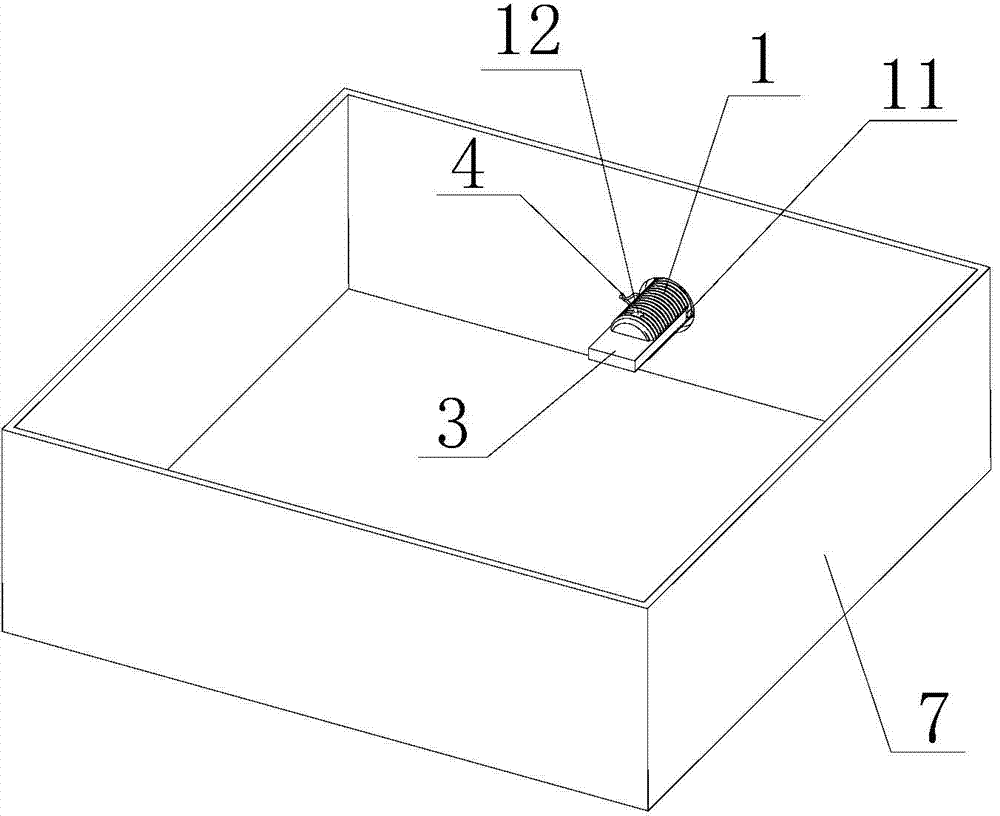

[0024] see figure 1 with figure 2 .

[0025] A plugging device, comprising a plugging body 1 , a nut 2 , a movable baffle 3 , a rigid pull wire 4 , a gasket 5 and a spring washer 6 . The plugging body 1 is a screw rod, and one end of the plugging body 1 is provided with a notch 11 extending along its axial direction, and the other end is connected with the nut 2; the gasket 5 and the spring washer 6 are interposed between the notch 11 and the nut 2, The spring washer 6 is interposed between the washer 5 and the nut 2; the movable baffle 3 is a rectangle, which is inserted into the notch 11 and fixed in the middle of the notch 11 through the radial shaft 12, and the radial shaft 12 passes through the movable baffle 3 center, the width of the movable baffle 3 is less than the diameter of the plugging body 1, and the length is greater than the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com