Cold trap device for gas chromatography of transformer insulating oil

A chromatographic analysis and transformer technology, which is applied in the field of cold trap devices, can solve problems such as difficult to meet the requirements of gas separation, and achieve the effect of uniform cooling, no penetration, and large heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

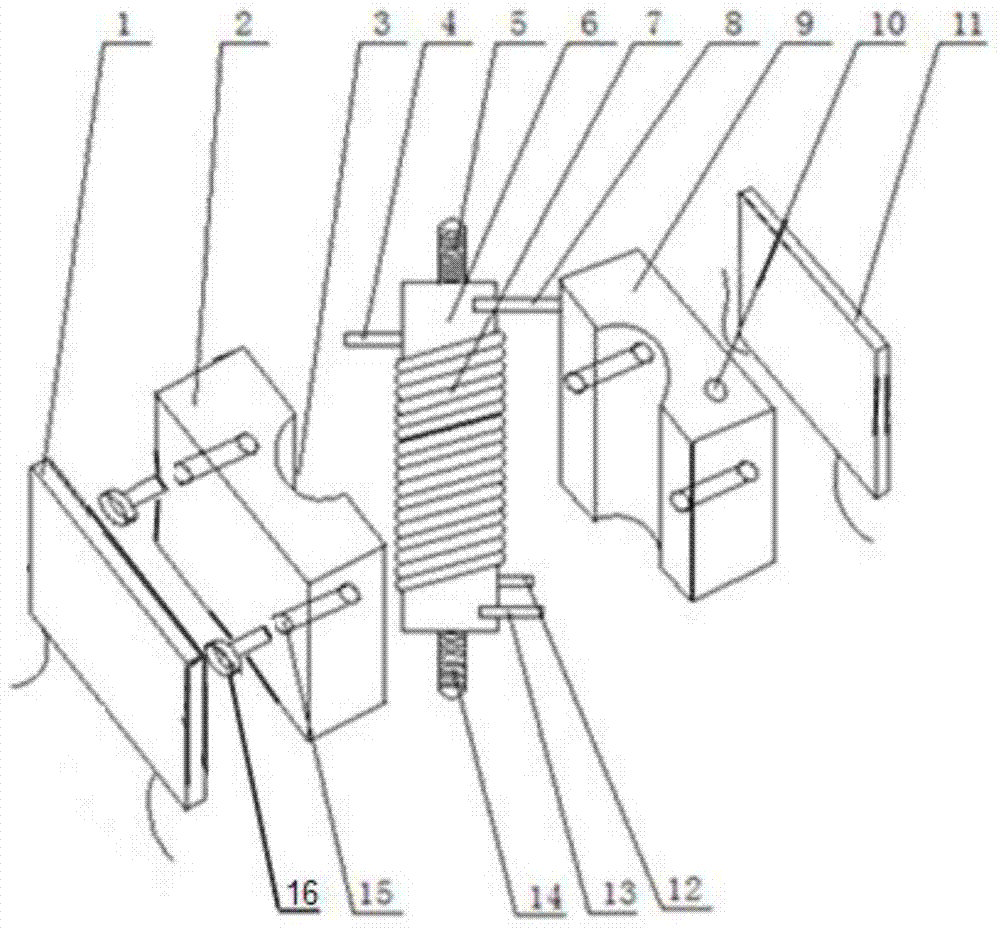

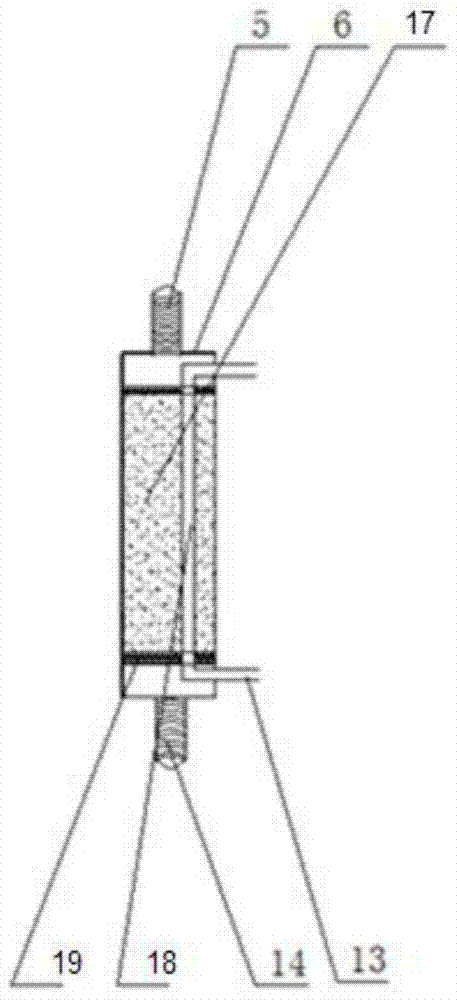

[0021] A cold trap device for gas chromatographic analysis of transformer insulating oil, such as figure 1 Or shown in 2, comprise cylindrical metal cold well housing 6, be integrally formed with the upper air inlet and outlet nozzle 5 that communicates with the housing inside on the upper top surface of housing, be integrally formed with housing on the lower bottom surface of housing The lower inlet and outlet gas nozzles 14 connected to the inside of the body are wound with metal external refrigeration pipes 7 outside the casing, and internal refrigeration pipes 18 are installed from top to bottom inside the casing, and the upper and lower ends of the cold trap casing are The porous plate 19 is fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com