Plant inspection method and system

An inspection system and plant technology, applied in the field of inspection, can solve the problems of statistical sorting, time-consuming and laborious, difficult and accurate execution of material preparation or maintenance, etc., to reduce the error rate and reduce the labor burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] For the convenience of description, in the following embodiments, similar elements are denoted by the same reference numerals.

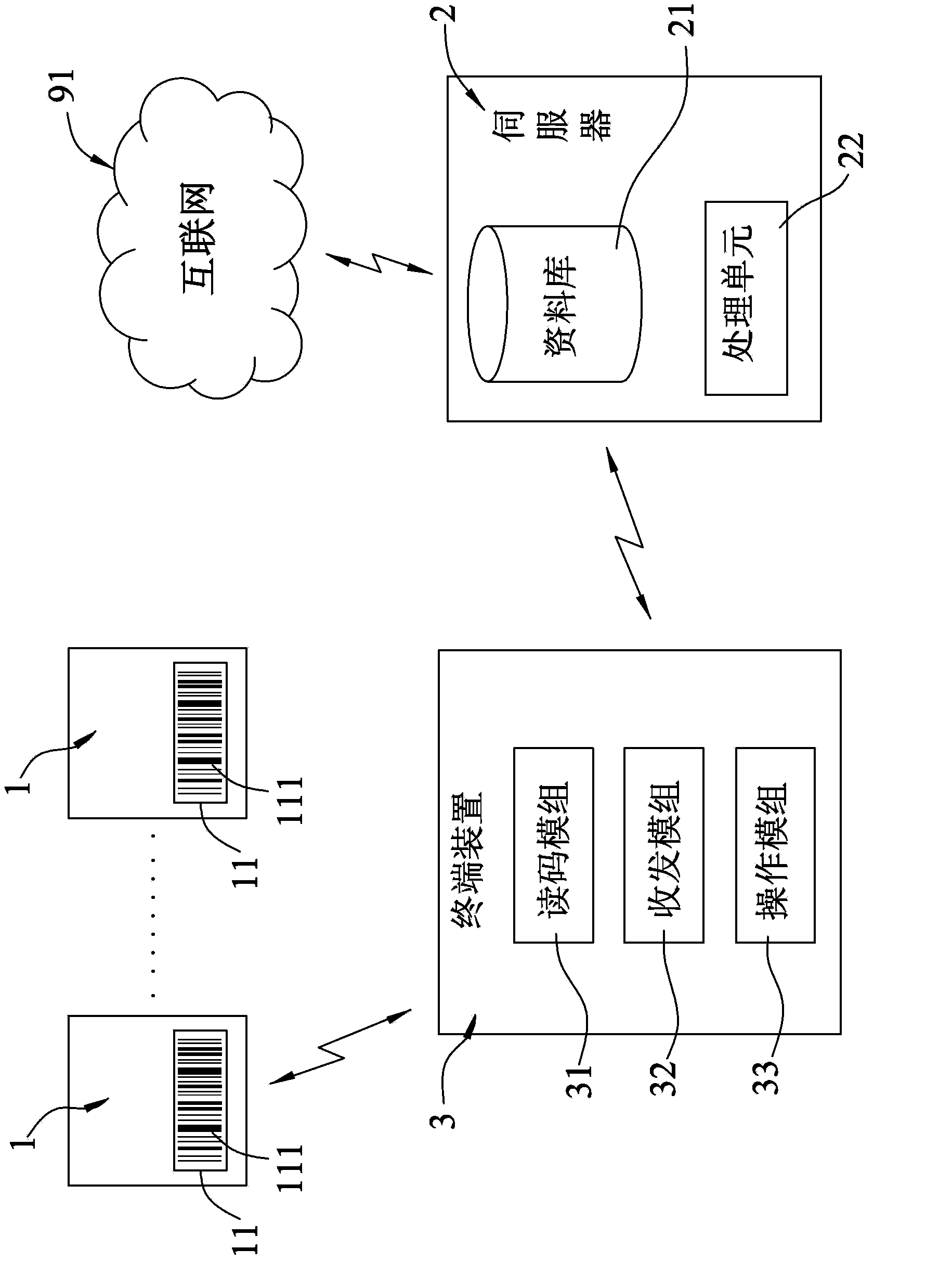

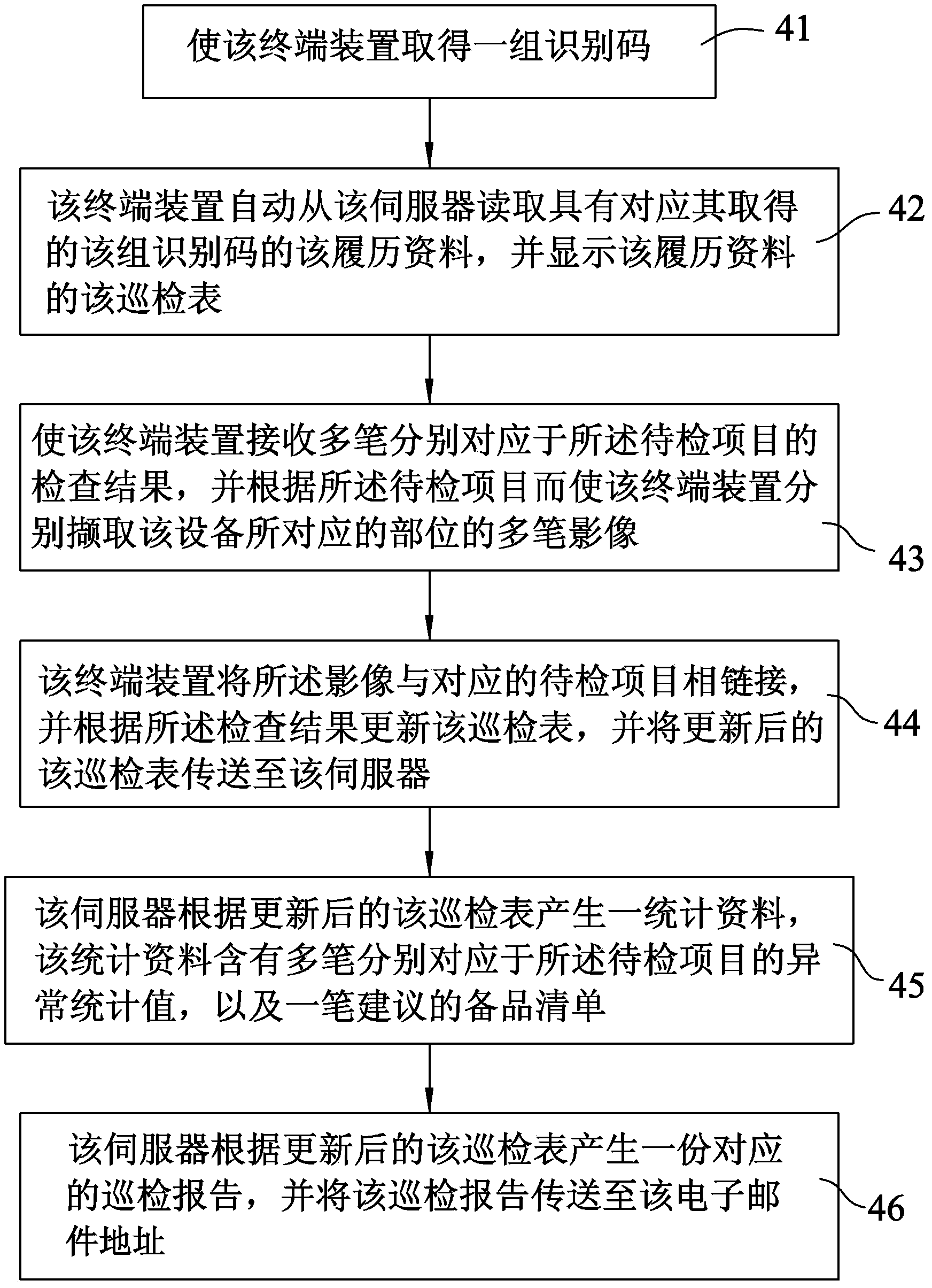

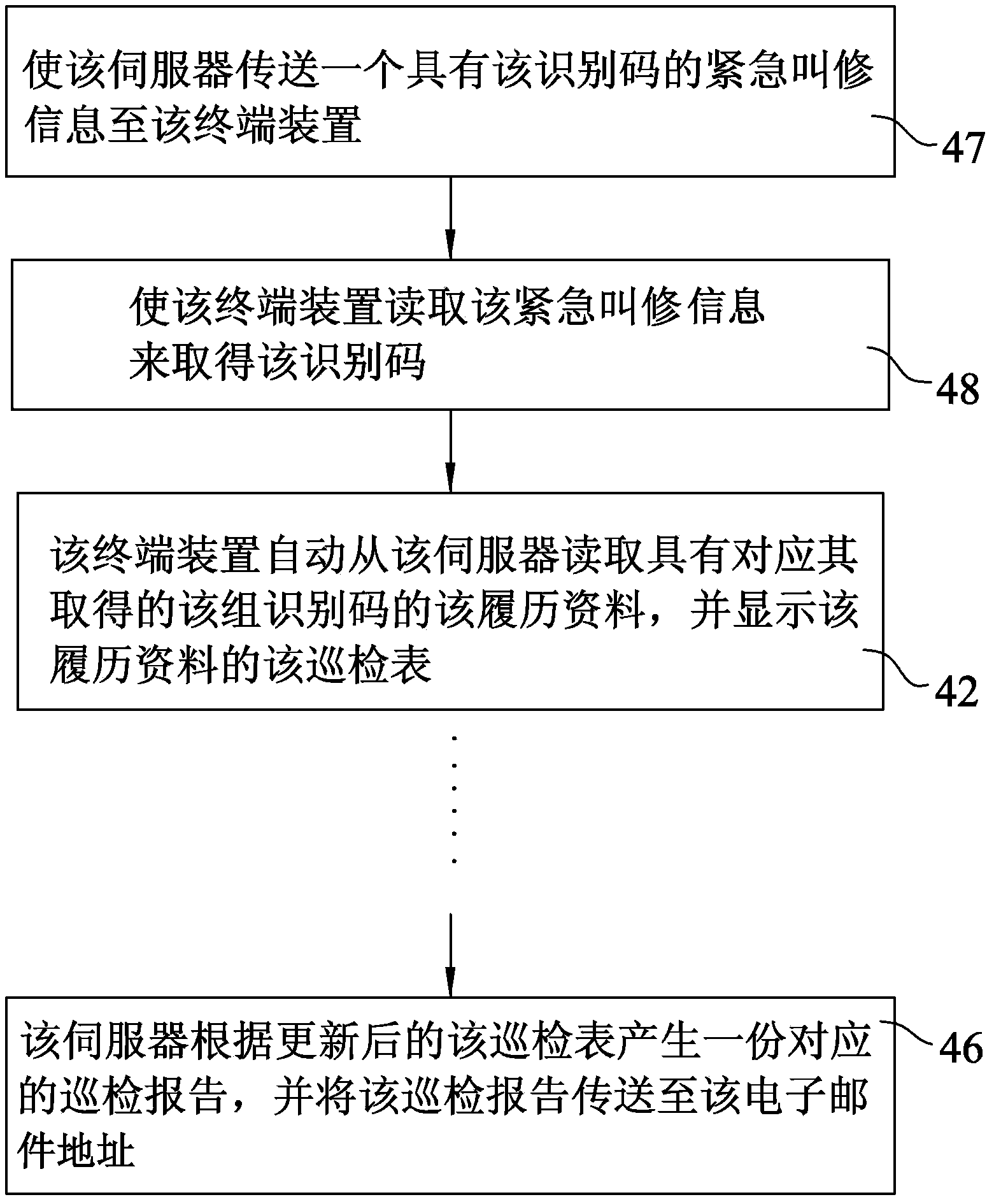

[0028] refer to figure 1 and figure 2 , is a first preferred embodiment of the plant inspection method of the present invention. During implementation, a plant inspection system is used for users to inspect multiple devices 1 of the plant. The devices 1 each have an identification element 11 . Each identification element 11 has a set of specific identification codes 111 built in. During implementation, the identification codes 111 can be presented in the form of one-dimensional barcodes, two-dimensional barcodes, numbers or radio frequency components. The identification codes of this preferred embodiment 111 is presented as a one-dimensional barcode.

[0029] The plant inspection system includes: a server 2 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com