Groove forming method

A trench and stage technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems affecting the isolation characteristics of isolation structures, and achieve the effect of enhanced oxidation and weakened etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

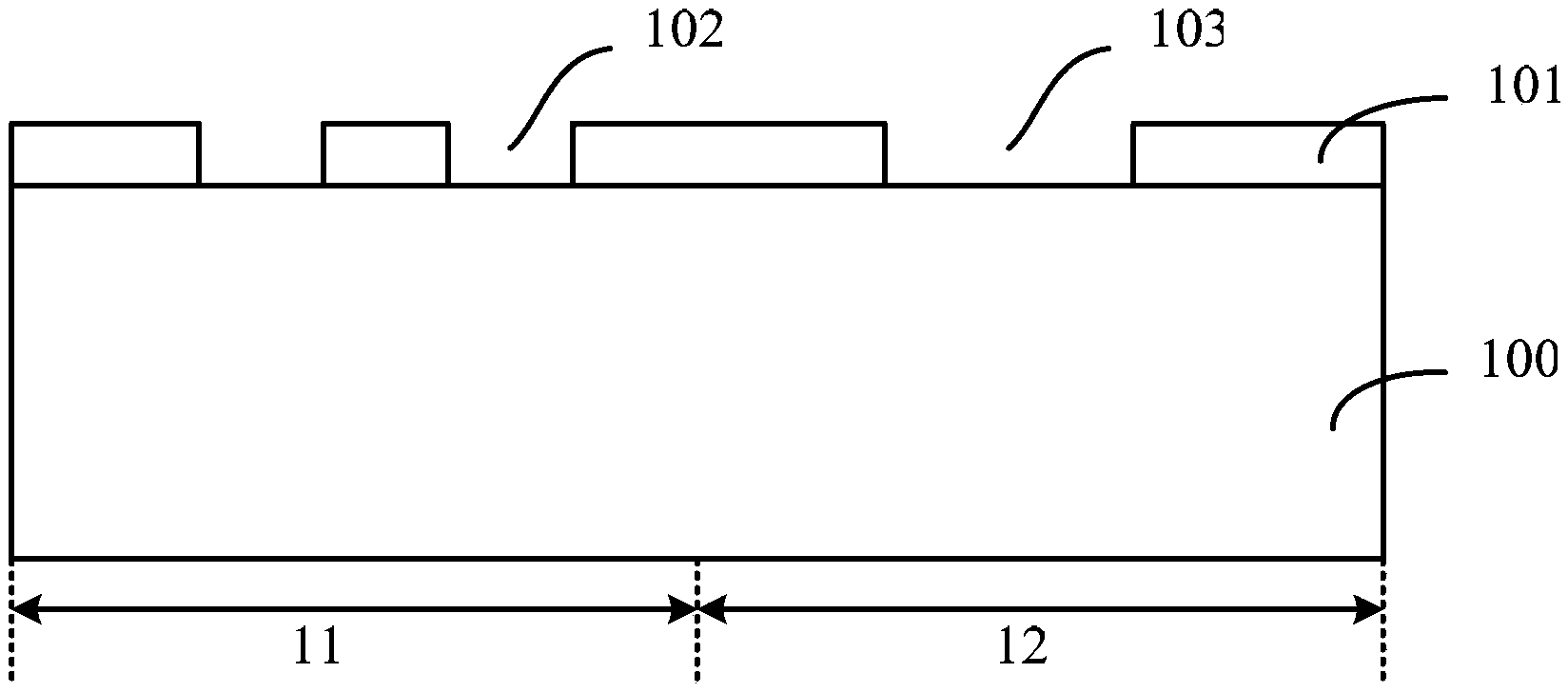

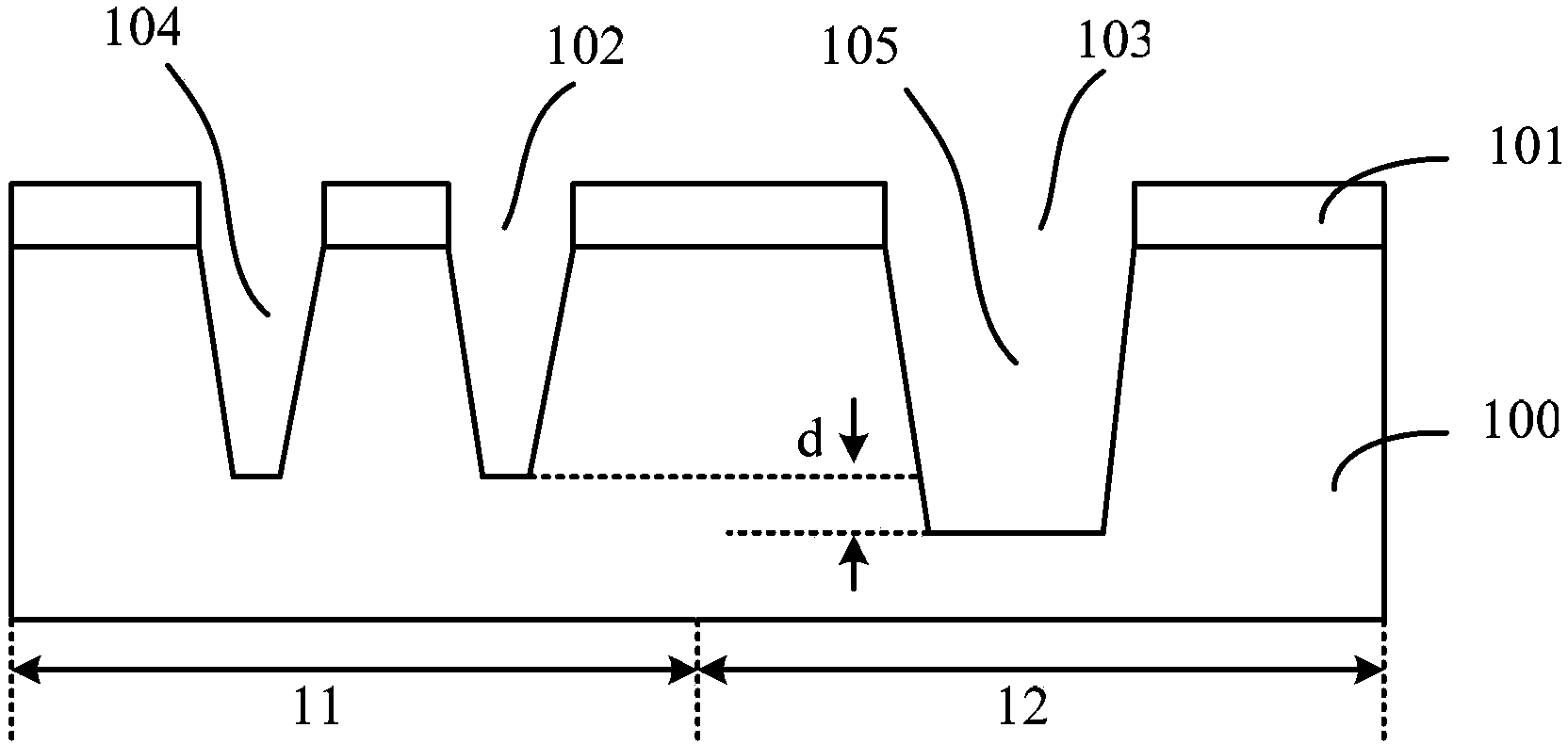

[0033] Please refer to figure 2 , the depth of the first trench 104 formed in the pattern dense area (first region 11 ) is smaller than the depth of the second trench 105 formed in the pattern empty area (second region 12 ) for shallow trenches formed in the prior art.

[0034] The inventors studied the process of forming shallow trenches in the prior art and found that since the width of the first trench 104 formed in the first region 11 is smaller than the width of the second trench 105 formed in the second region 12, the When the semiconductor substrate 100 is etched by a plasma etching process, the exchange rate of the etching plasma and the etching by-products in the first trench 104 will be smaller than that of the etching plasma and the etching by-products in the second trench 105. Exchange rate, thus the etch rate of the semiconductor substrate of the first region 11 will be less than the etch rate of the semiconductor substrate of the second region 12, and in the etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com