Light emitting diode module

A technology of light-emitting diodes and modules, which is applied to the semiconductor devices, optics, light sources and other directions of light-emitting elements to achieve the effect of weakening the intensity, reducing the difference in light intensity and making effective use of it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

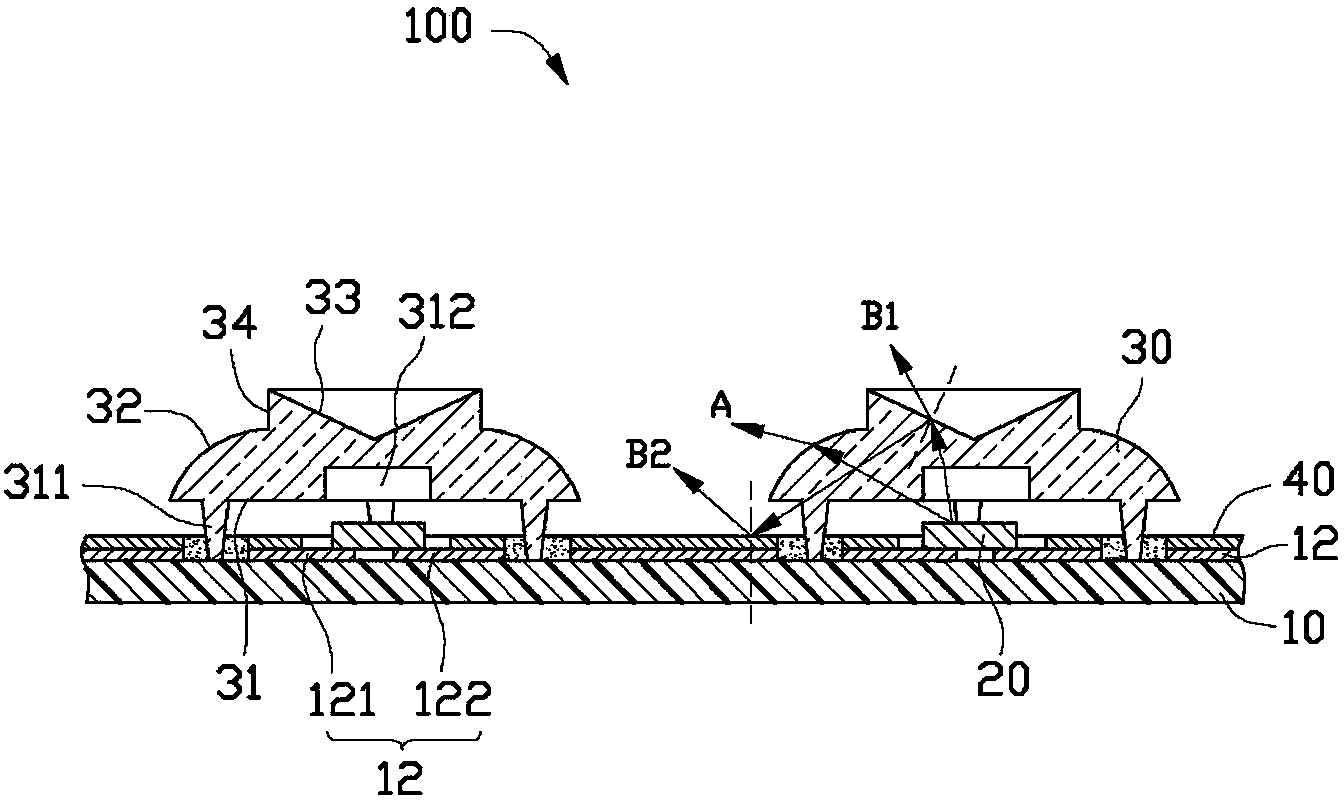

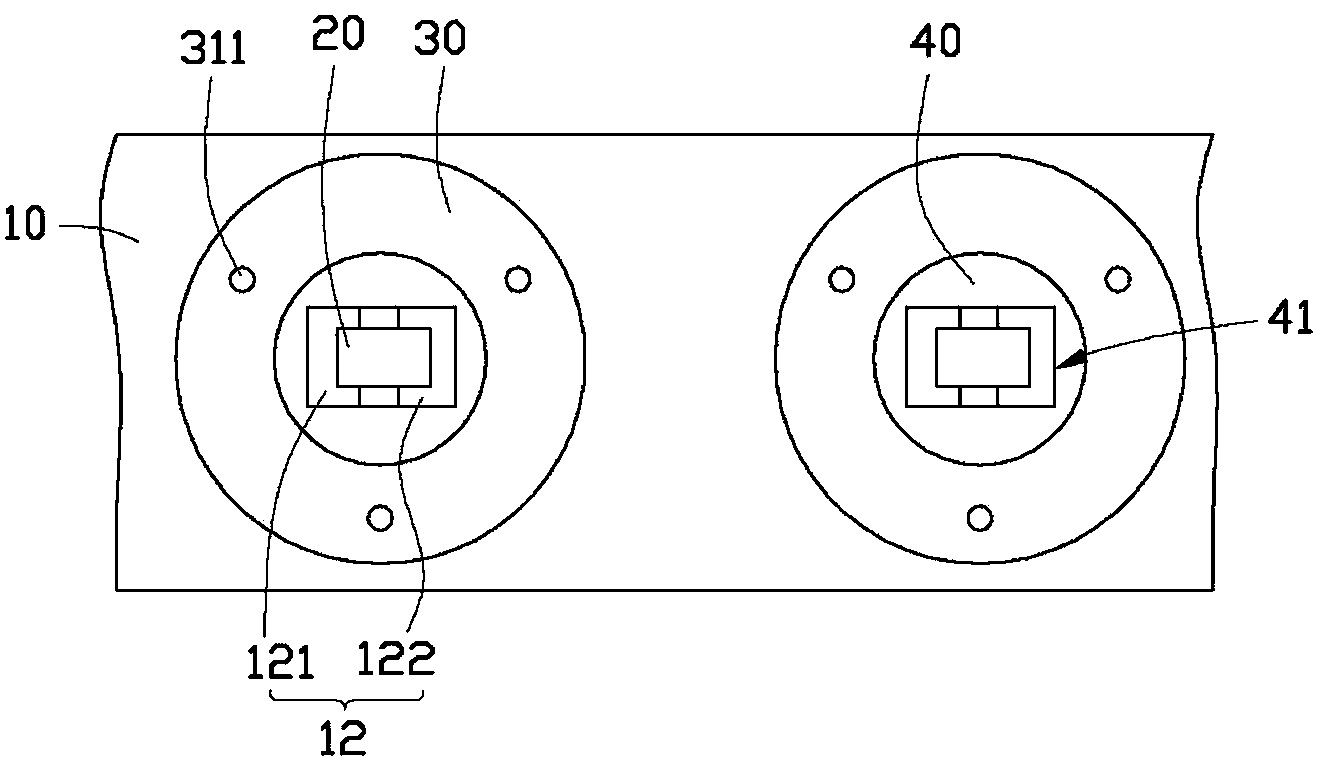

[0015] See figure 1 and figure 2 , an LED module 100 provided by an embodiment of the present invention includes a circuit board 10 , LEDs 20 mounted on the circuit board 10 , and a lens 30 covering each LED 20 .

[0016] The circuit board 10 is used to carry the LED 20 and fix the lens 30 , and electrically connect the LED 20 to an external power source to provide power for the LED 20 . Please also see figure 2 , the circuit board 10 is roughly strip-shaped, and the circuit board 10 includes an insulating substrate and a circuit layer 12 formed on the substrate for electrically connecting the LEDs 20 to the circuit board 10 . The circuit layer 12 includes a plurality of first circuits 121 and second circuits 122, two adjacent first circuits 121 and second circuits 122 are spaced apart from each other, and each LED 20 is connected to two adjacent first circuits 121 and second circuits. circuit 122.

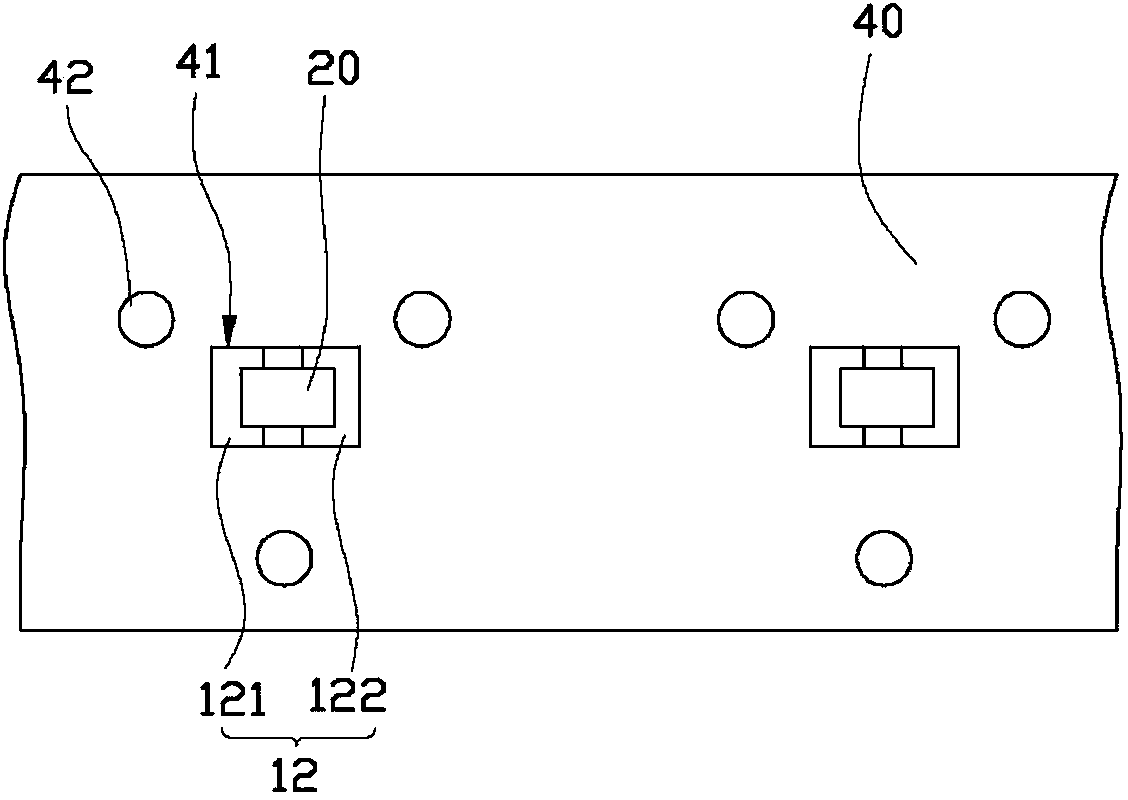

[0017] Please also see image 3 , the circuit board 10 is further prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com