Mixing reaction observation device

An observation device and reaction technology, applied in the fields of biological extraction, chemical industry, and reaction, can solve the problem of inability to observe the reaction of the tank in real time, and achieve the effect of saving working time and manpower, convenient operation, and reducing observation and climbing ladders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

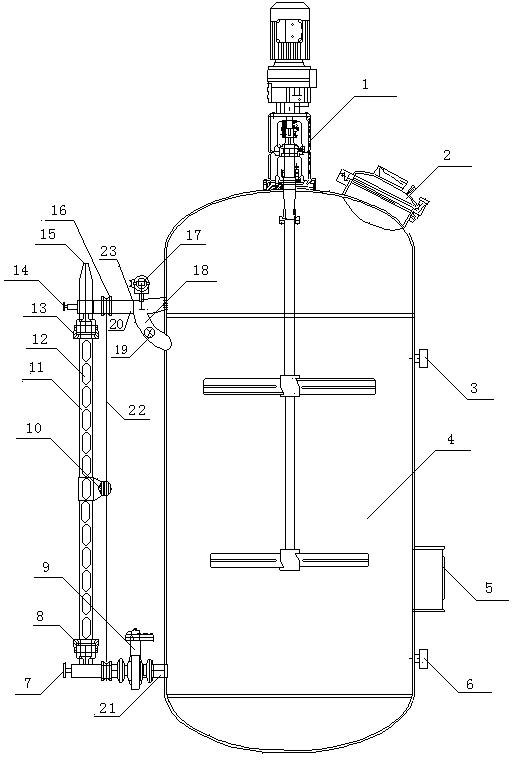

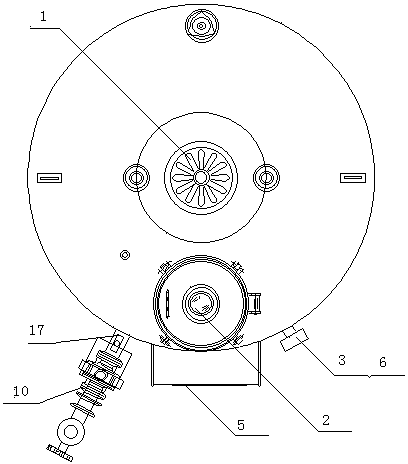

[0022] Such as figure 1 - figure 2 As shown, a compounding reaction observation device of the present invention includes a compounding reaction tank 4, an agitator 1 and a manhole 2 arranged in the compounding reaction tank 4 through a motor and a coupling. A pH value sensor 3 and the second pH value sensor 6, the equipment electrical control cabinet 5 is set between the first pH value sensor 3 and the second pH value sensor 6; the described deployment reaction tank 4 and the equipment electrical The upper and lower ends of the opposite side of the control cabinet 5 are provided with an upper connecting pipe 20 and a lower connecting pipe 21 connected to the deployment reaction tank 5, and the lower end of the observation pipe 12 is vertically connected with the lower connecting pipe 21 through the lower observer threaded interface 8, and the upper end of the observation pipe 12 The threaded interface 13 of the upper observer is vertically connected to the upper connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com