Frame assembly welding error prevention device

A frame assembly welding and error-proofing technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of easy deformation of welding parts, improve production capacity, reduce thermal expansion and cold contraction deformation, reduce rework and other problems. The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

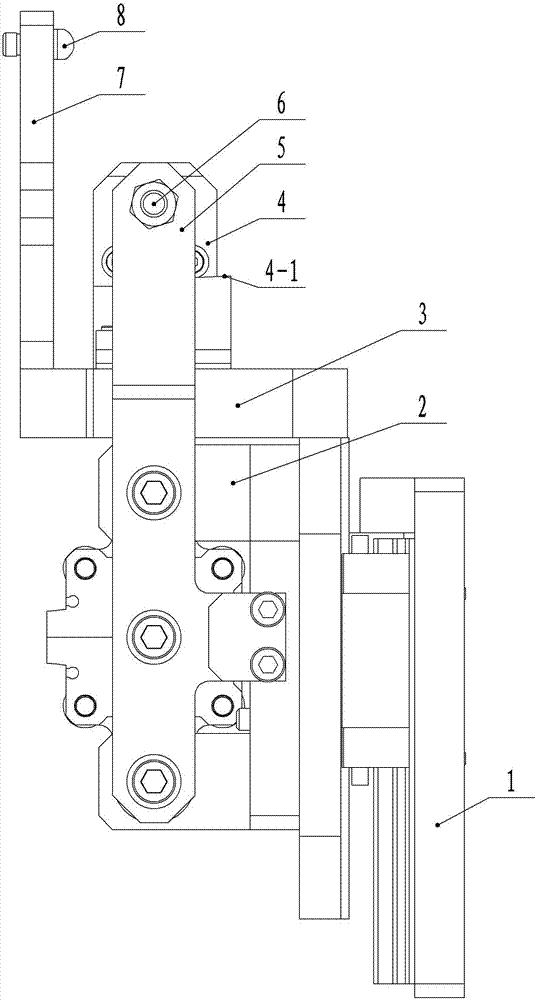

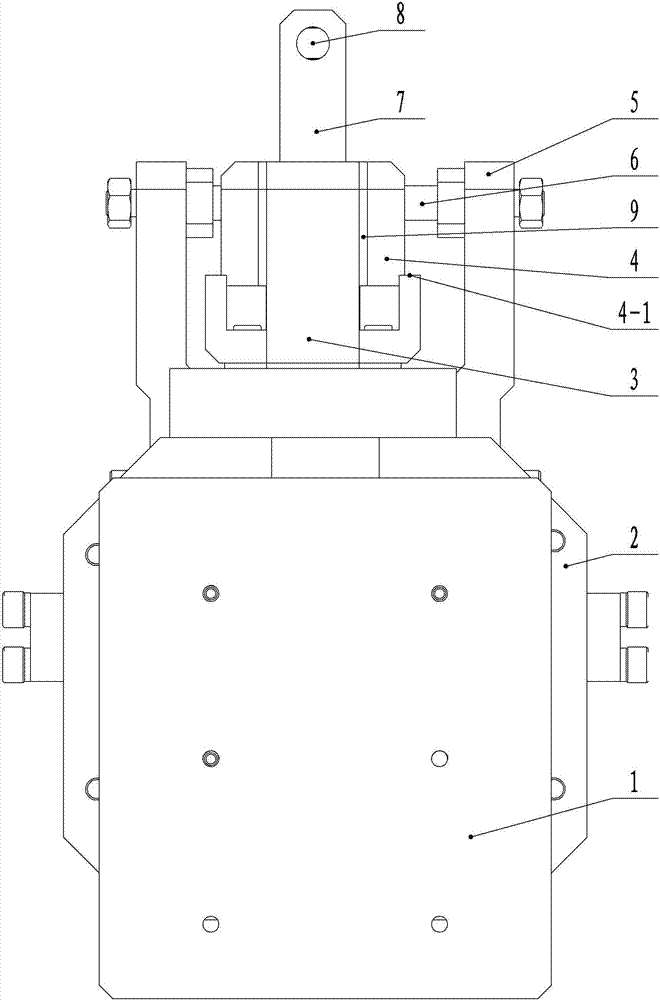

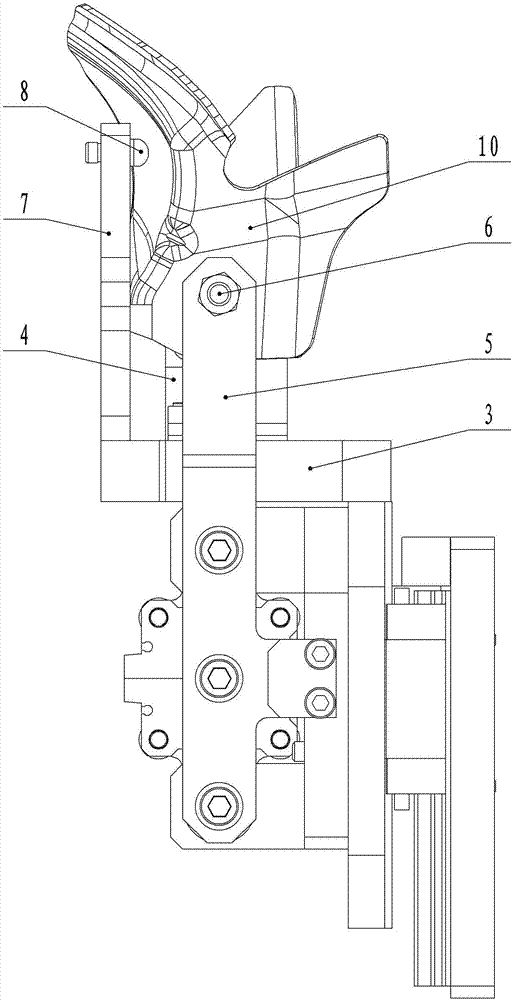

[0013] figure 1 and figure 2 The frame assembly welding error prevention device shown is a part of a large welding tool. It is a clamp body. The clamp body mainly includes a mounting plate 1, a positioning support 2, a clamping arm and a locking bolt 6, and the mounting plate 1 is used to install the clamp body on the bottom plate of the welding workbench, the positioning support 2 is movably connected with the mounting plate 1, the clamping arm is fixedly installed on the positioning support 2, and the clamping arm is fixedly connected to the positioning support 2 Two oppositely arranged first clamping arms 5 and a second clamping arm 7 are provided with a profiling block matching the welding workpiece between these clamping arms, and the second clamping arm 7 and the profiling block The clamping direction is perpendicular to the clamping direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com