Liquid electronic chemical quantitative filling machine

A technology of electronic chemicals and filling machines, applied in the chemical industry, can solve the problems of precision limitation, large feeding error, high cost, etc., and achieve the effects of stable liquid pressure, small space occupation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

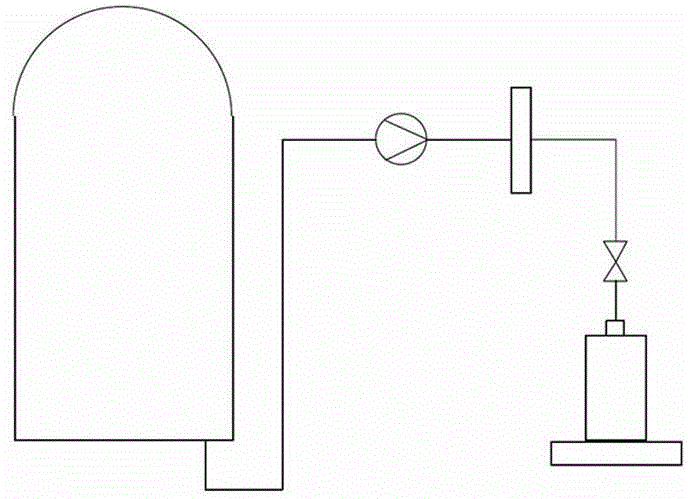

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

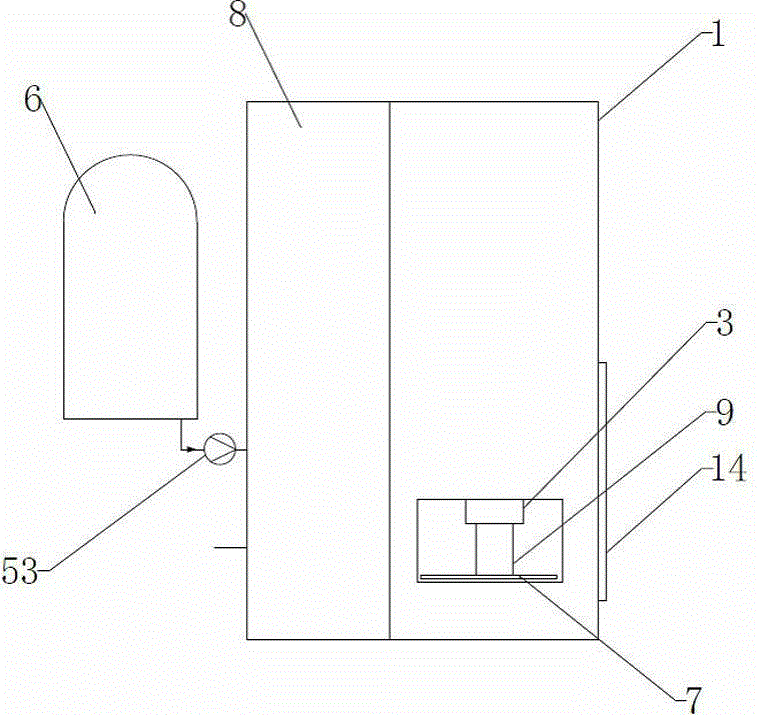

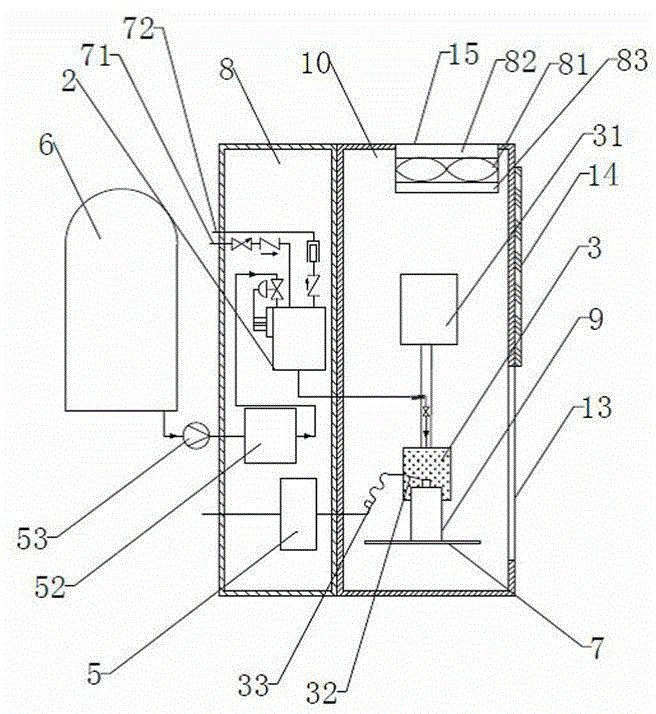

[0032] The present invention is a quantitative filling machine for liquid electronic chemicals, such as Figure 2 to Figure 6 As shown, it includes a purification cabinet 1, a transmission mechanism, a filling mechanism, and a storage tank 2; the cleanliness level of the purification cabinet 1 is above 100, and there are inlet gates 11 and outlet gates 12 on both sides of the lower part of the purification cabinet 1; the transmission mechanism includes The conveyor belt 7 used to transport the packaging drum 9 into and out of the purification cabinet 1, the conveyor belt 7 extends from the gate 11 to the gate 12 and extends out of the purification cabinet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com