Portable insulation cover airtightness detector

A detector and air flow detection technology are applied in the field of portable thermal insulation cover air tightness detectors to achieve the effect of convenient mobile access and light equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples.

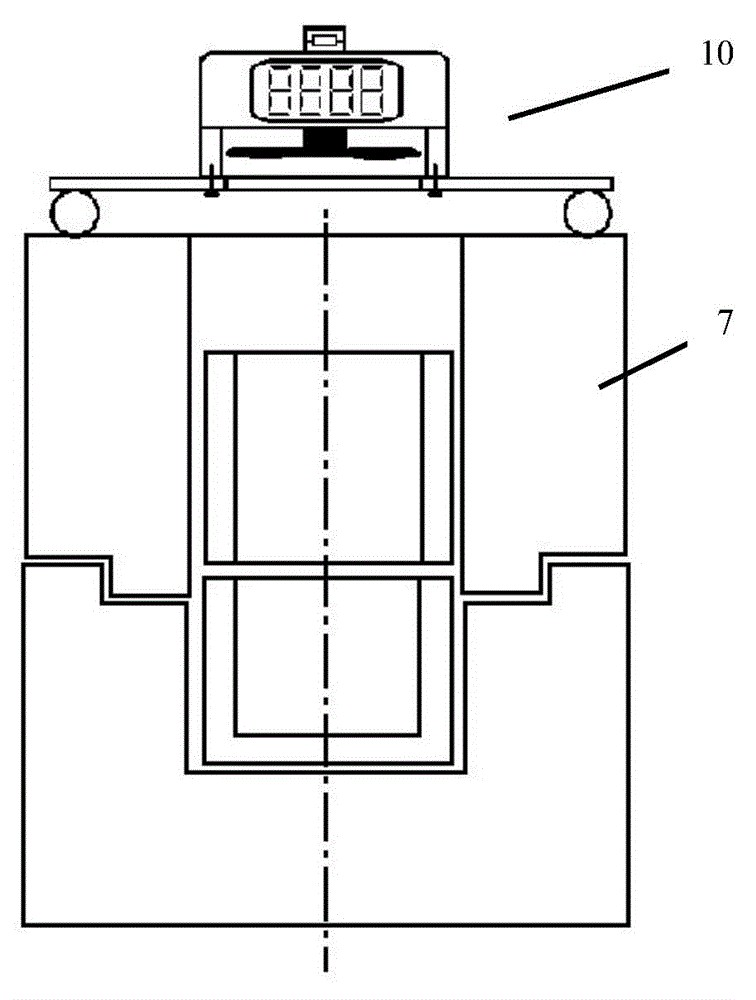

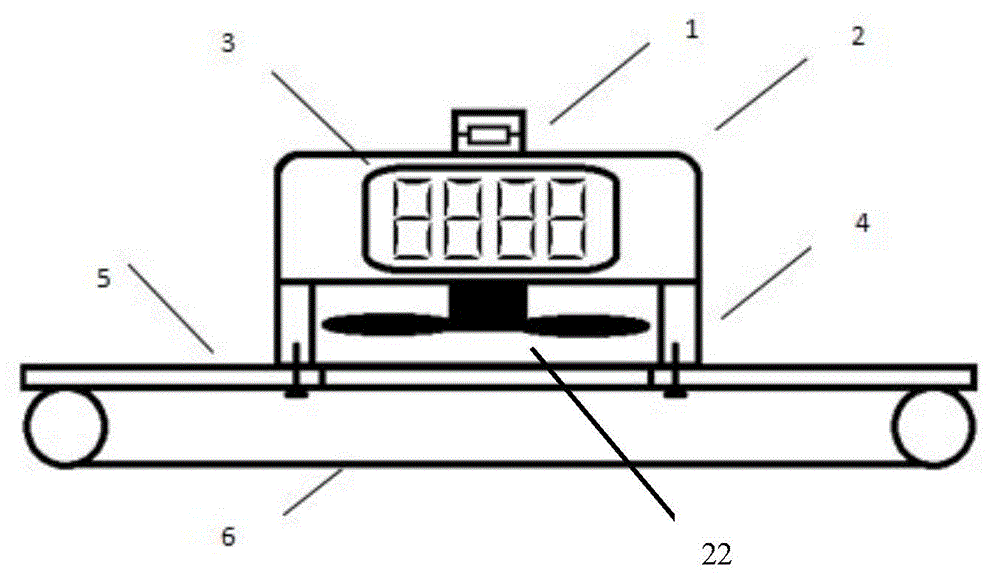

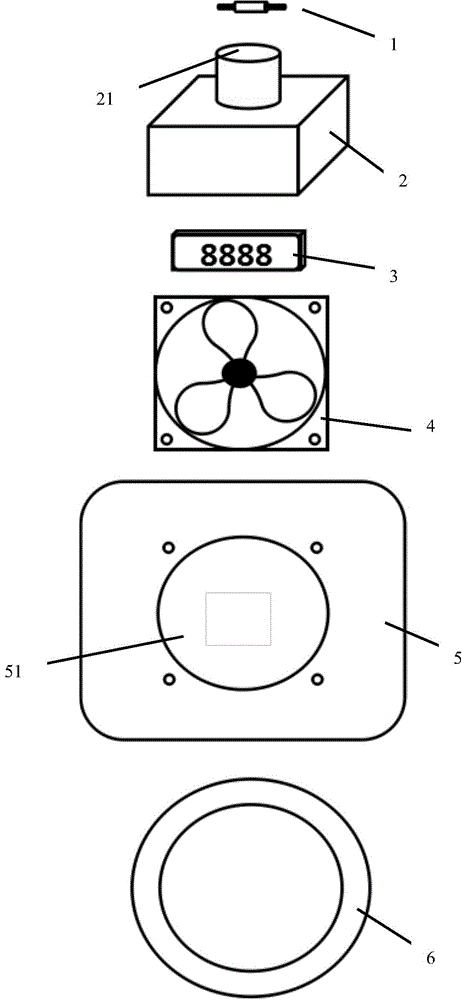

[0017] Such as Figure 1 to Figure 3 As shown, the present invention discloses a portable thermal insulation cover air tightness detector 10, which includes an airflow detection element 1, an air guide housing 2, a processing module and a display panel 3, and an airflow providing device 4; the airflow providing device 4 passes through the thermal insulation cover 7 The opened through hole provides air flow to the inside of the heat preservation cover 7, the air flow detection element 1 is used to detect the air flow speed, the air guiding shell 2 is used to make all the gas flow into the heat preservation cover 7, and the processing module and the display panel 3 are used to receive and process the air flow from the air flow detection The information of element 1, calculates and displays the leak rate value. The airflow detection element 1 detects the airflow velocity and fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com