A high-efficiency and low-consumption combined formwork system and its construction method

A combined formwork and construction method technology, which is applied in the field preparation of formwork/formwork components and building components, construction, etc., can solve the problems of high construction cost, low safety performance, slow erection speed of fastener-type steel pipe scaffolding, etc. , to achieve the effect of reducing construction consumption and improving social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

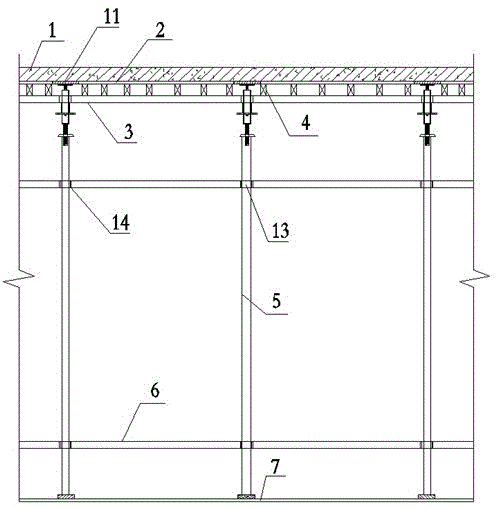

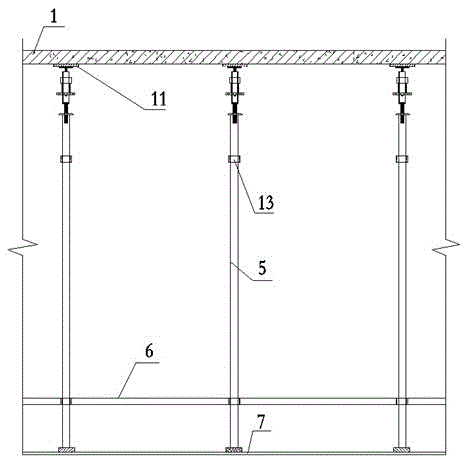

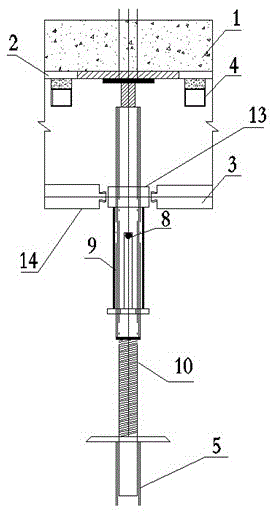

[0020] Such as figure 1 , 2 As shown, the high-efficiency and low-consumption combined formwork system of the present invention includes early demolition parts and non-early demolition parts. The templates 11 that will not be dismantled early are arranged alternately in rows and intervals under the concrete floor 1; The two ends of the rod 3 are supported on the vertical pole 5 and can move up and down to fix or remove the early demolition template 2 . Cross bar 3 and described vertical pole 5 joints are provided with an early dismantling head, and the lower side of template 11 is supported on the vertical pole 5 by this early dismantling head. A sweeping rod 6 is also provided near the concrete structure surface 7 . The height of the sweeping rod 6 from the concrete structure surface 7 is determined according to relevant specifications. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com