Method and device for controlling temperature of SCR reactor

A technology of SCR reactor and control method, which is applied in the direction of noise reduction device, exhaust device, electric control of exhaust gas treatment device, etc., can solve the problems of overshoot or slow response speed, unstable temperature of SCR reactor, etc. Hysteresis, improve stability, improve the effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

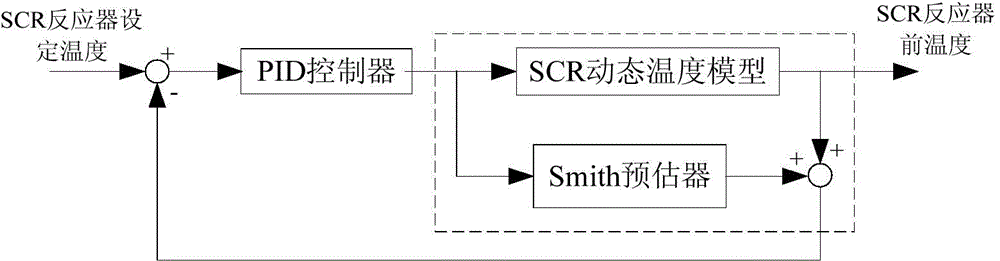

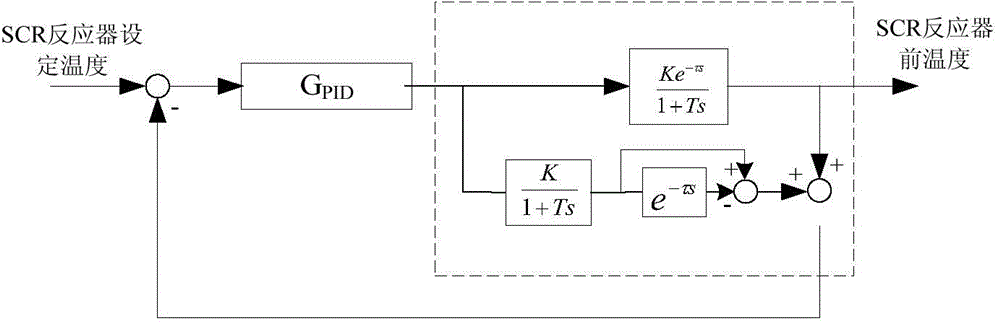

[0041] The specific implementation of the method for controlling the temperature of the SCR reactor provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

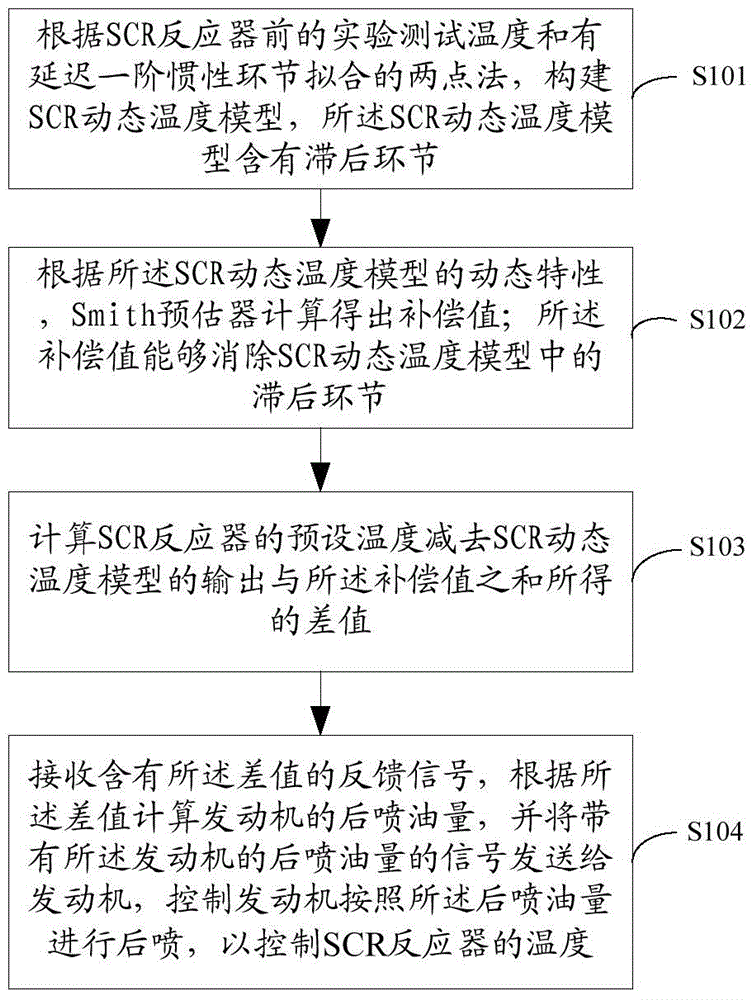

[0042] see figure 1 , figure 1 It is a schematic flow chart of the method for controlling the temperature of the SCR reactor provided by the embodiment of the present invention. Such as figure 1 As shown, the control method includes the following steps:

[0043] S101. According to the experimental test temperature before the SCR reactor and the two-point method with delayed first-order inertia link fitting, construct the SCR dynamic temperature model, and the SCR dynamic temperature model contains a hysteresis link:

[0044] Usually, the post-injection of the engine is used in this technical field to control the exhaust temperature of the engine exhaust, but the SCR reactor is usually located after the oxidation catalytic device DOC and the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com