Hydraulic ejector

A technology of hydraulic injectors and nozzles, which is applied in the direction of jet pumps, machines/engines, steam/steam condensers, etc., and can solve problems such as damage to parts at the bottom of the injector, difficulty in controlling the spray water flow, and large impact force of the injector, etc., to achieve The effect of prolonging the service life, facilitating large-scale promotion and use, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

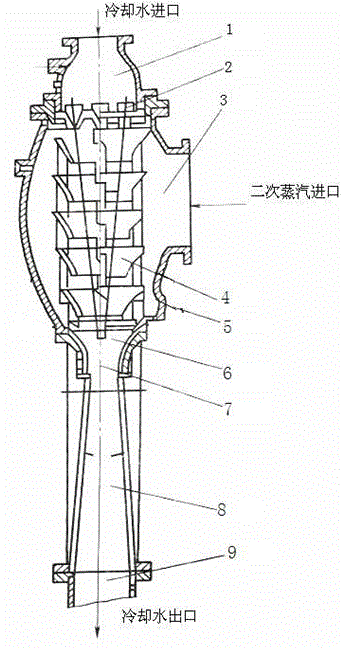

[0015] see figure 1 , a water power injector, which includes: the water power injector includes a body 5, a nozzle 2, a suction chamber 3, a mixing chamber 6 and a diffusion chamber 8 arranged on the body, the nozzle 2 is sequentially provided with suction Air chamber 3, mixing chamber 6 and diffusion chamber 8, the suction chamber is provided with a conical guide baffle. In this technical solution, a conical guide baffle is ingeniously arranged in the suction chamber, which plays a role in buffering and distributing the high-speed water flow. Due to the limited internal space of the injector, the conical guide baffle involved in this technical solution not only It only solves the impact problem of the water flow on the injector in the prior art, improves the working efficiency and prolongs the service life of the injector.

Embodiment 2

[0017] see figure 1 , as an improvement of the present invention, the hydraulic injector further includes a throat 7 , and the throat 7 is arranged between the mixing chamber 6 and the diffusion chamber 8 . The throat pipe is connected with the water flow coming down from the baffle plate to further ensure the guidance of the water flow and ensure that the water flow can reach the outlet of the cooling water quickly and accurately. All the other structures and advantages are identical to Embodiment 1.

Embodiment 3

[0019] see figure 1 , as a kind of improvement of the present invention, the diameter of described nozzle 2 is 15-20mm, proves through many experiments, the size of nozzle diameter plays a key role to pumping effect, and the diameter of nozzle is preferably 16-18mm, Further ensure the pumping effect. All the other structures and advantages are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com