Pohotonic crystal fiber grating pressure sensing method adopting bimodal reflectance spectrum of cross-polarized mode

A photonic crystal fiber, orthogonal polarization technology, applied in the direction of force measurement by measuring the change of optical properties of materials when they are stressed, can solve problems such as the inability to measure lateral stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

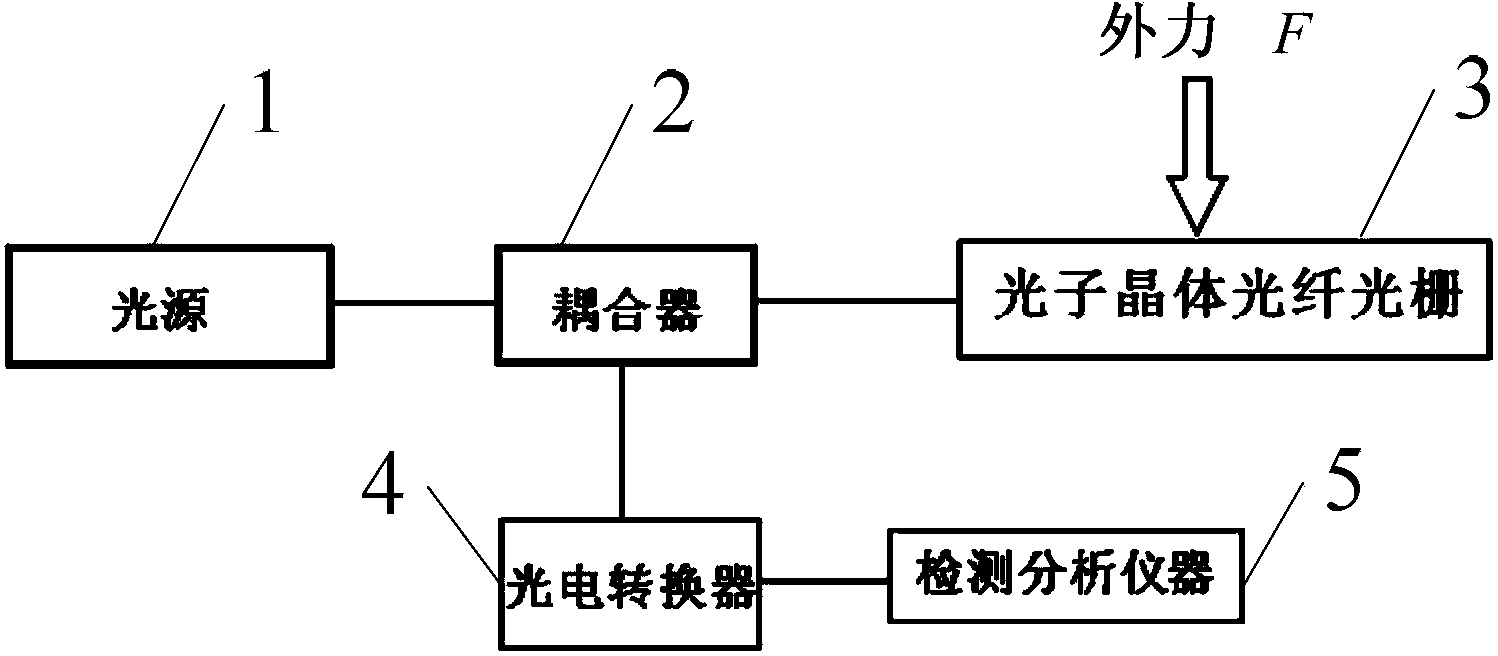

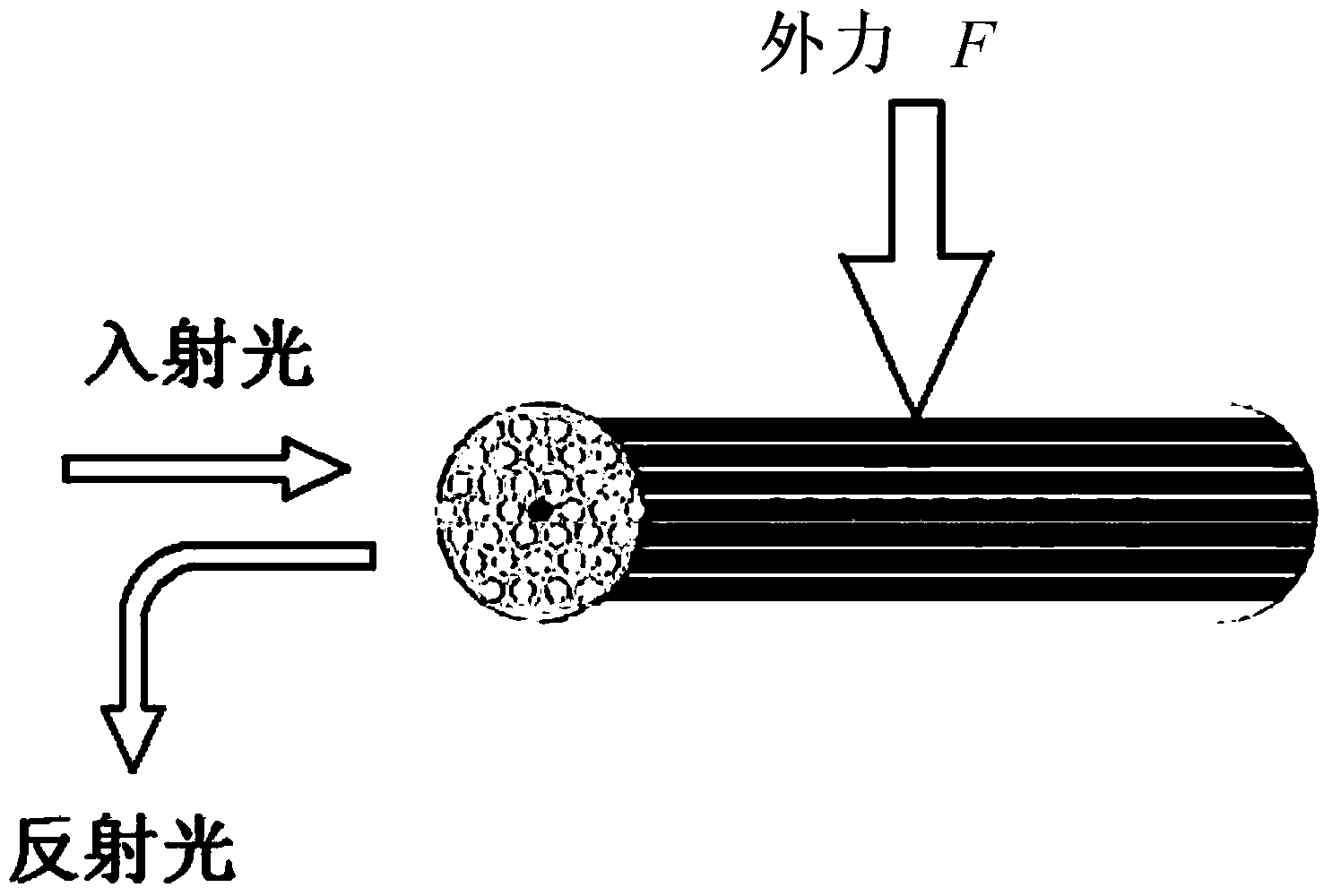

[0038] Specific implementation mode one: see figure 1 and 2 Describe this embodiment mode, a kind of pressure sensing method using the photonic crystal fiber grating of orthogonal polarization mode bimodal reflection spectrum described in this embodiment mode, the specific process of this method is:

[0039] The light emitted by the light source 1 is coupled by the coupler 2 and then incident on the photonic crystal fiber grating 3 to which the external force F perpendicular to the photonic crystal fiber grating 3 has been applied. The photonic crystal fiber grating 3 generates reflected light, which is coupled by the coupler 2 Sent to the photoelectric converter 4, the electrical signal output by the photoelectric converter 4 is sent to the detection and analysis instrument 5;

[0040] The specific process of detecting and analyzing instrument 5 to obtain the value of external force F is as follows:

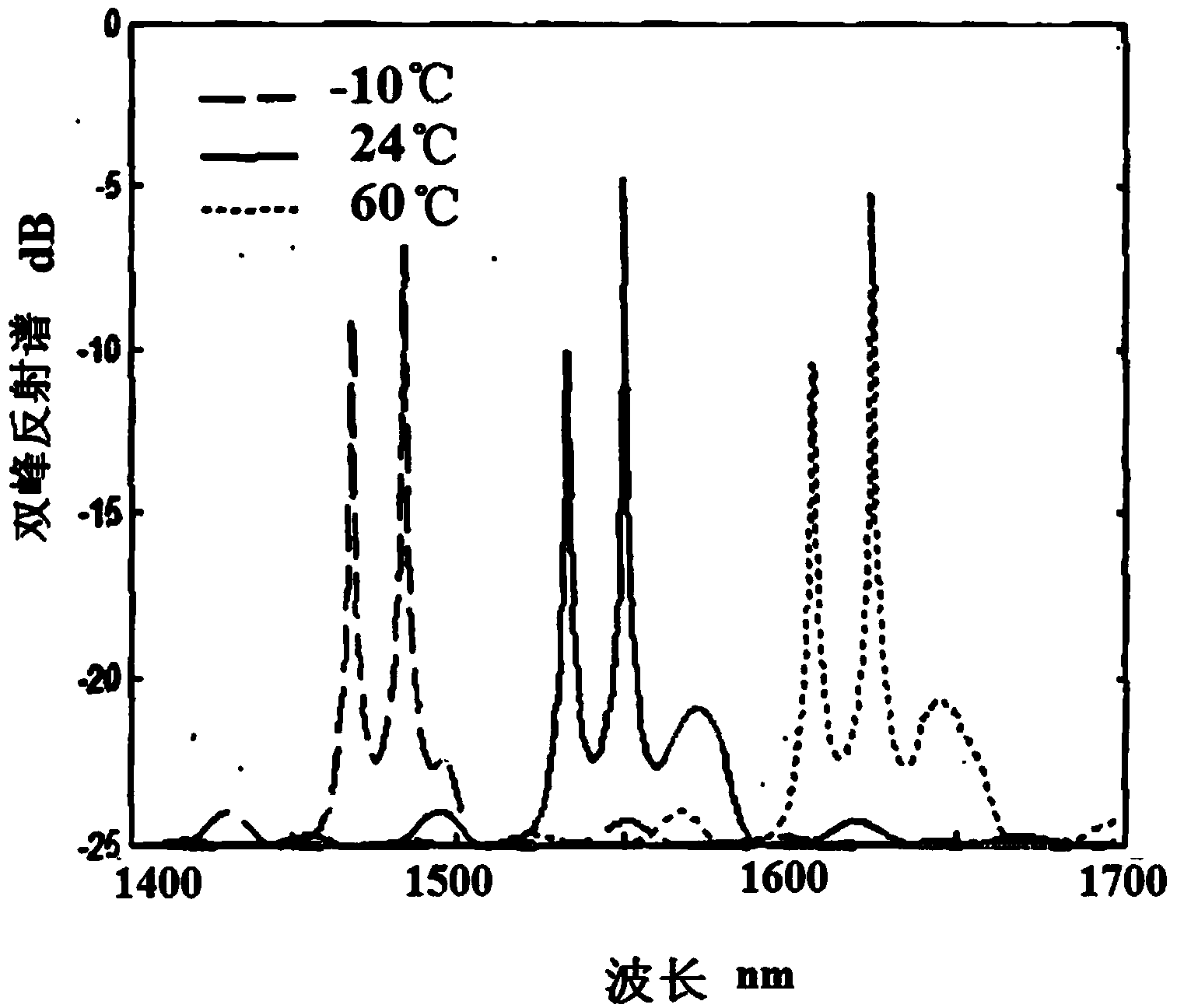

[0041] When an external force F perpendicular to the photonic crystal fi...

specific Embodiment approach 2

[0049] Specific embodiment 2: The difference between this embodiment and the pressure sensing method of a photonic crystal fiber grating using the bimodal reflection spectrum of the orthogonal polarization mode described in the specific embodiment 1 is that the K x (ε) and K y The calculation process of (ε) is,

[0050] When the photonic crystal fiber grating 3 is subjected to an external force F, the wavelength change of reflected light as follows,

[0051] d λ b λ b = dn co n co - n cl - dn cl n co - n ...

specific Embodiment approach 3

[0063] Specific embodiment three: The difference between this embodiment and the pressure sensing method of a photonic crystal fiber grating using the orthogonal polarization mode bimodal reflection spectrum described in the specific embodiment one is that the light emitted by the light source 1 is Broad spectrum natural light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com