Auto-focusing actuator driving structure

A focal actuator and drive structure technology, applied in the direction of instruments, installation, optics, etc., can solve the problems of complex assembly, failure to meet the requirements, and bulky coils, etc., and achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

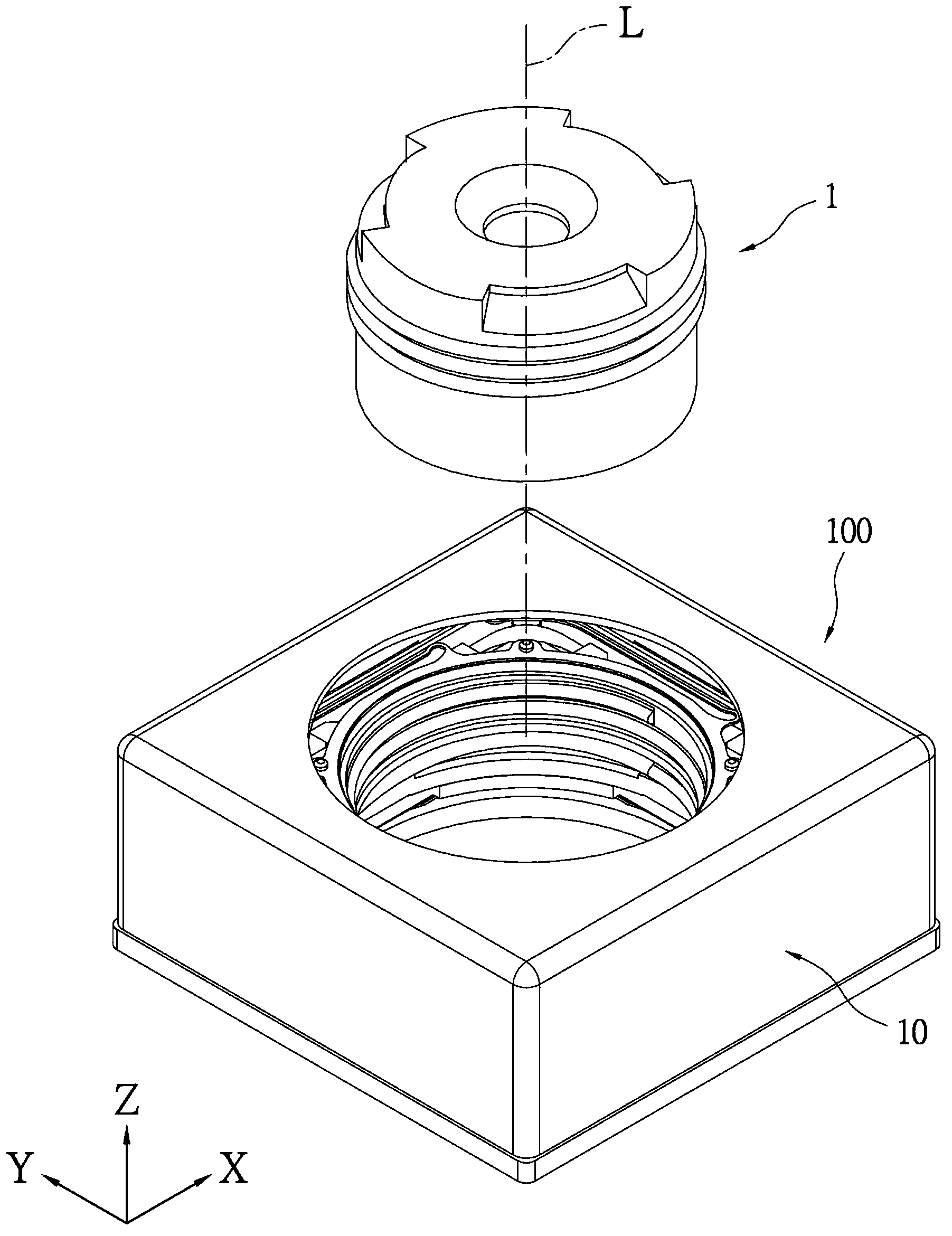

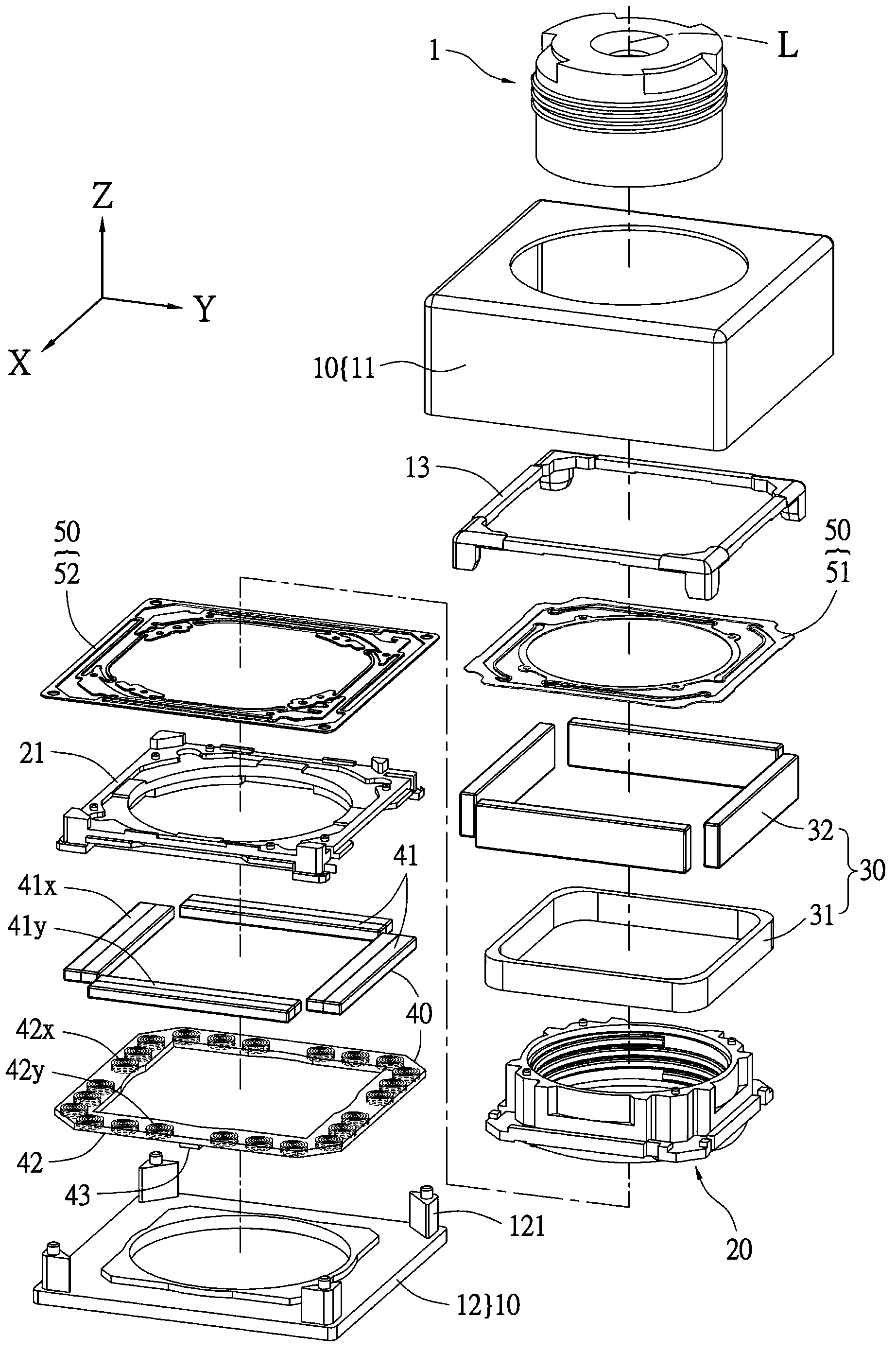

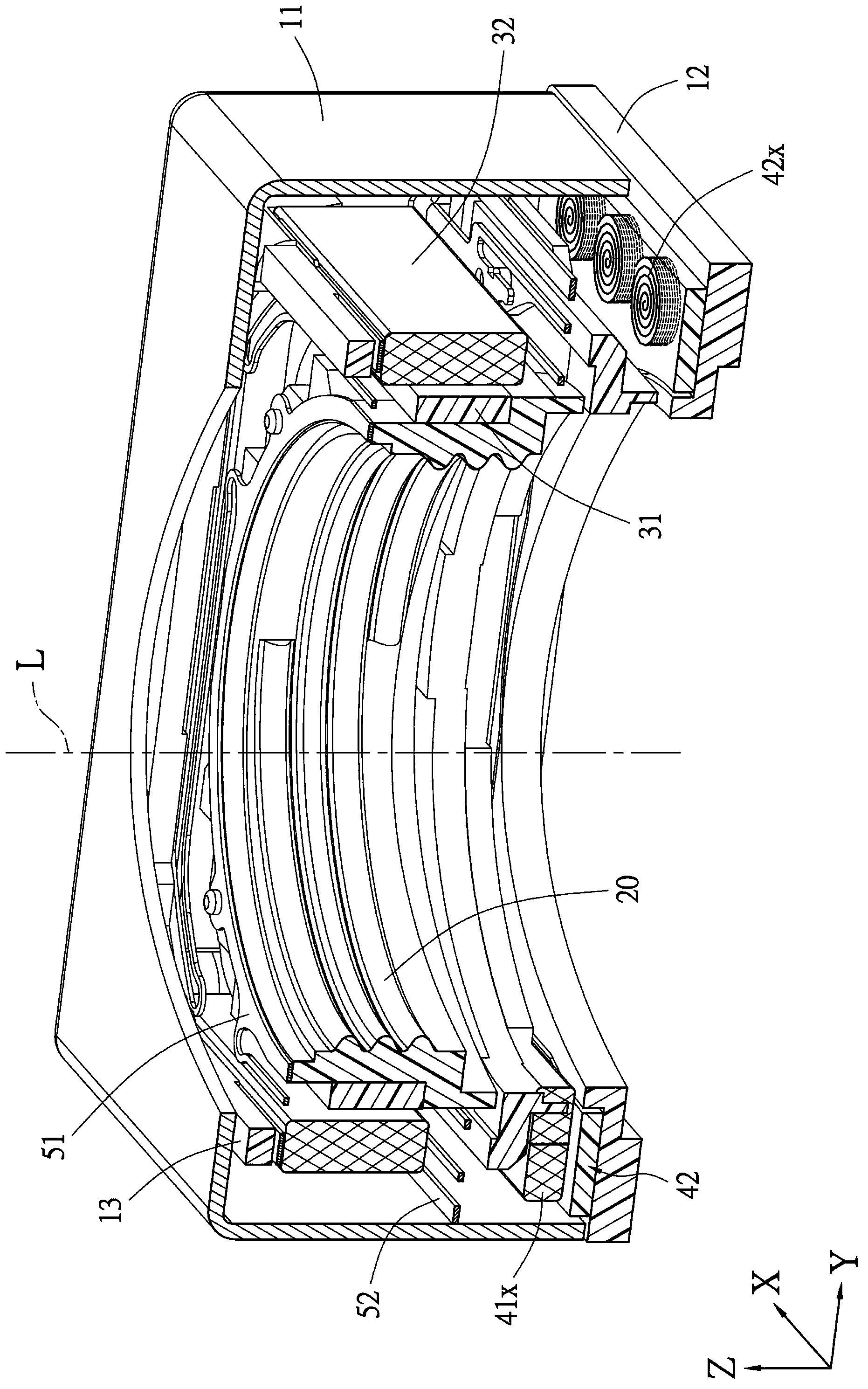

[0072] Please refer to figure 1 , the present embodiment provides an autofocus actuator driving structure 100 which can be mounted on a lens 1 . please refer again figure 2 and image 3 , the autofocus actuator driving structure 100 of this embodiment basically includes a body 10 , a lens barrel 20 , a carrier 21 , a first driving unit 30 and a second driving unit 40 .

[0073] The above-mentioned body 10 includes a frame body 11 and a base body 12 . Wherein, the frame body 11 is preferably made of metal material, the seat body 12 is preferably mainly made of plastic material, and the seat body 12 is assembled with the frame body 11 and located at the bottom of the main body 10 .

[0074] The above-mentioned lens barrel 20 is movably disposed inside the main body 10 . The lens barrel 20 is for the lens 1 to be mounted therein, and the lens 1 and the lens barrel 20 have the same optical axis L, the direction of the optical axis L can be defined as the Z-axis direction, and...

no. 2 example

[0082] Please refer to Figure 4 to Figure 6 In this embodiment, the autofocus actuator driving structure 200 basically includes a body 10', a lens barrel 20' and a driving unit 30'. The main difference between this embodiment and the above-mentioned embodiments is that the autofocus actuator driving structure 200 of this embodiment has only one driving unit 30 ′, and the driving unit 30 ′ includes a coil circuit board 31 ′ and a magnetic element group 32 '. The magnetic element group 31' is fixed on the outside of the lens barrel 20', the coil circuit board 32' is arranged inside the body 10' and surrounds the lens barrel 20' and the magnetic element group 32', and the coil circuit board 32' has several The printed coils 311x, 312x, 311y, 312y correspond to the positions of the magnetic element group 31'.

[0083] Specifically, the magnetic element group 31' includes at least two X-axis magnets 321x, 322x, and two Y-axis magnets 321y, 322y, and each X-axis magnet 321x, 322x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com