An explosion-proof power distribution box

A technology of power distribution box and power distribution rack, applied in the direction of substation/distribution device shell, etc., can solve the problems of large use risk, fire, short-circuit electric shock parts, etc., and achieve good isolation effect, improve safety, and good fire alarm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

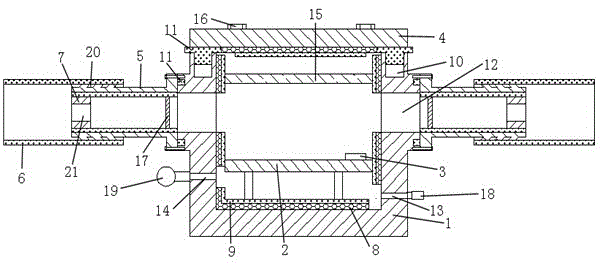

[0008] Such as figure 1 As shown, an explosion-proof power distribution box is composed of a wiring compartment 1, a power distribution frame 2, a smoke alarm 3, a sealing cover 4, a lead pipe 5, a heat shrinkable sleeve 6 and a rubber block 7, wherein the wiring compartment 1 and The sealing cover 4 is connected by bolts 16, and the inner wall of the wiring chamber 1 and the inner surface of the sealing cover 4 are additionally provided with an insulating ceramic coating 8, and the insulating ceramic coating 8 is additionally coated with a flame-retardant PVC cushion 9, At least one sealing groove 10 is provided on the abutting surface of the junction chamber 1 and the sealing cover 4, and a sealing strip 11 is provided at the corresponding position of the sealing cover 4 and the sealing groove 10, wherein the height of the sealing strip 11 is 0.5-5% of the depth of the sealing groove 10. 2 times, the width is the same as the width of the sealing groove 10, at least two wirin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com