Forming process of flexible spiral polymer clay body and processing equipment and accessories of flexible spiral polymer clay body

A molding process and flexible technology, which is applied in the field of molding process of flexible soft pottery body, can solve the problems of uneven patterns, inability to mass-produce, uneven thickness of patterns, etc., achieve good weather resistance, facilitate mass production, The effect of short baking times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

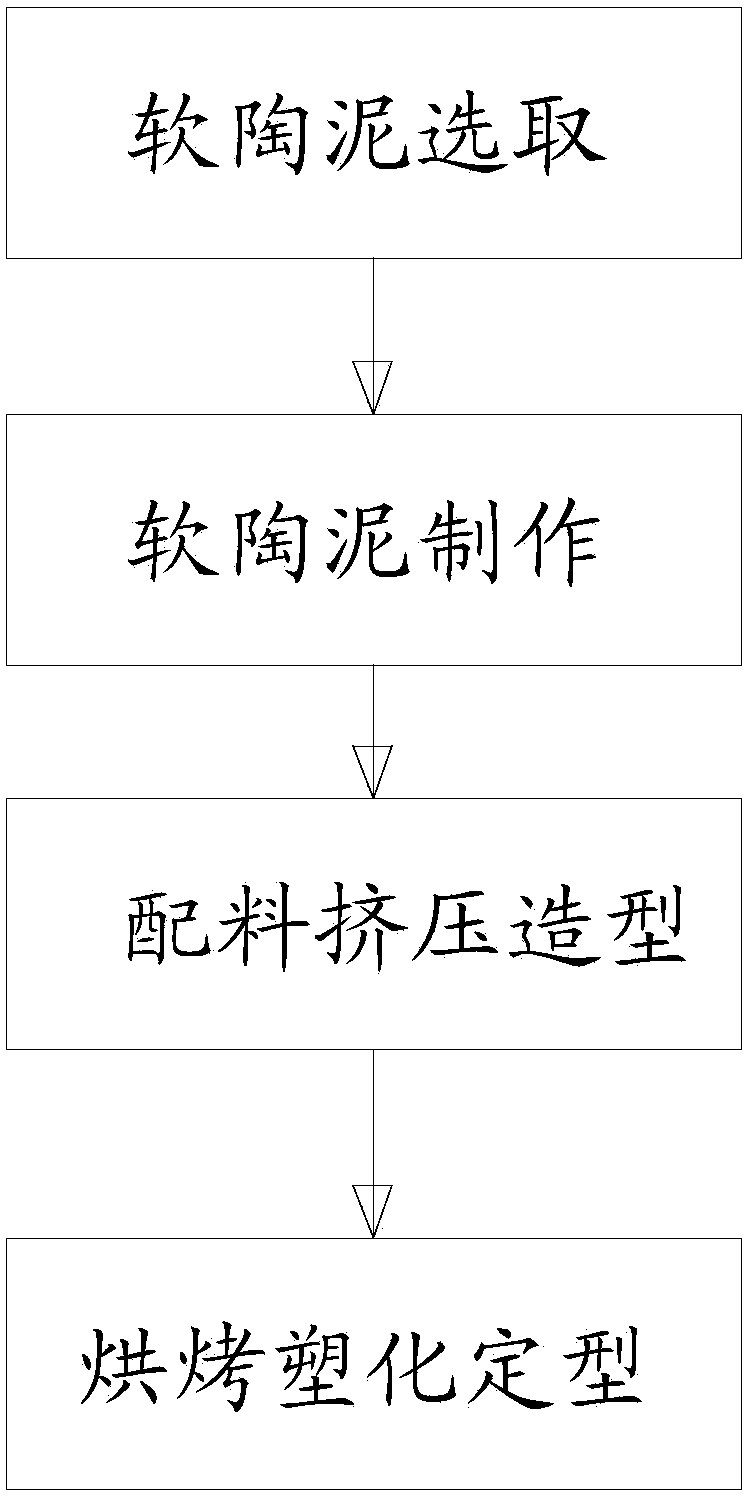

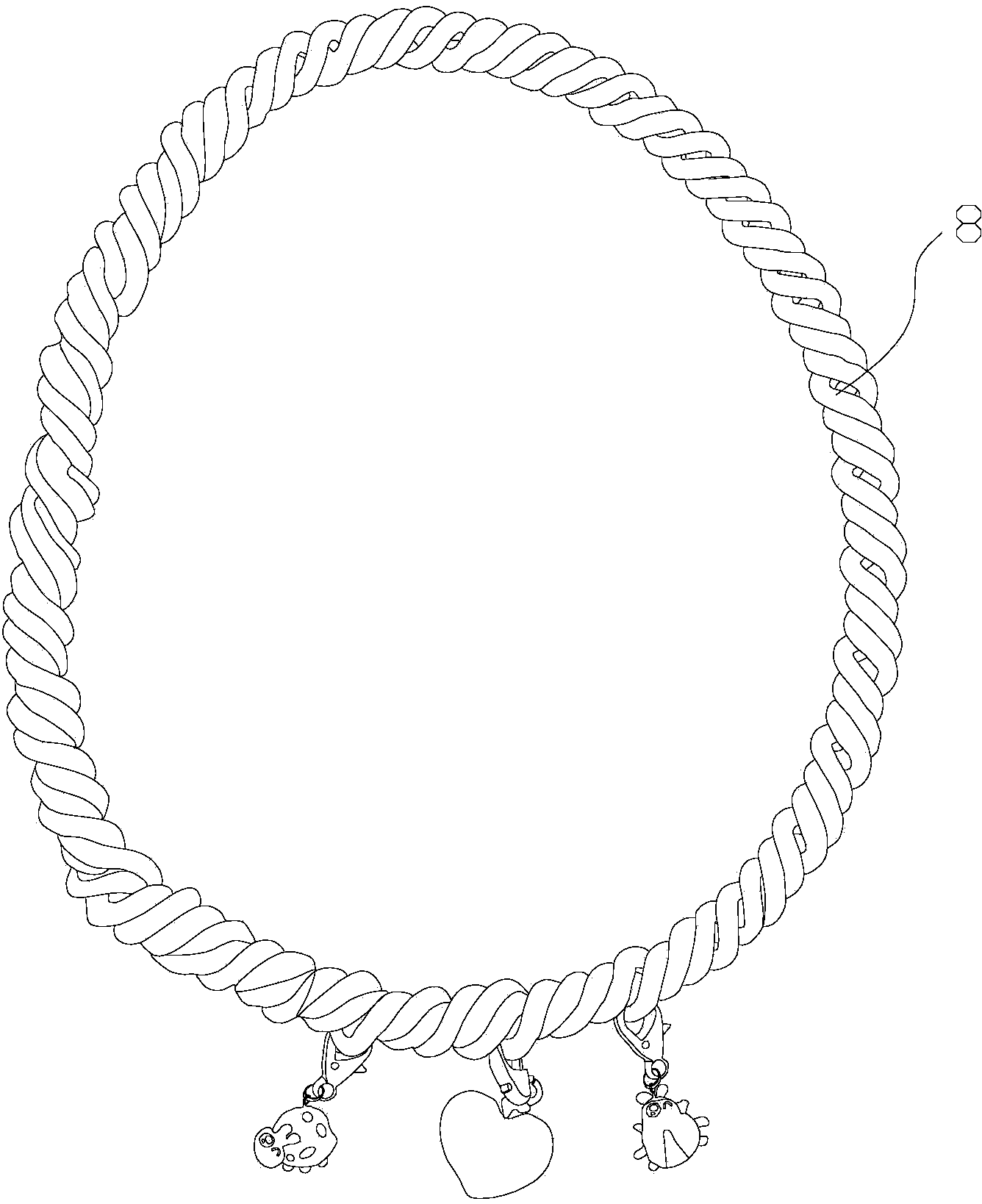

[0053] The molding process of flexible spiral soft ceramic body, such as Figure 1 to Figure 3 , Figure 10 shown, including the following steps:

[0054] a. Soft clay selection:

[0055] According to the spiral lines of four different colors on the polymer body, choose four colors of polymer clay;

[0056] b. The production of soft clay:

[0057] Make the four colors of soft clay into long strips of the required size, and cut one end of the long strip into a cone shape;

[0058] c. Ingredients extrusion molding:

[0059] This step includes:

[0060] c1. Neatly stack the strip-shaped blanks of four colors together, place the conical ends of all the strip-shaped blanks at the same end and align them;

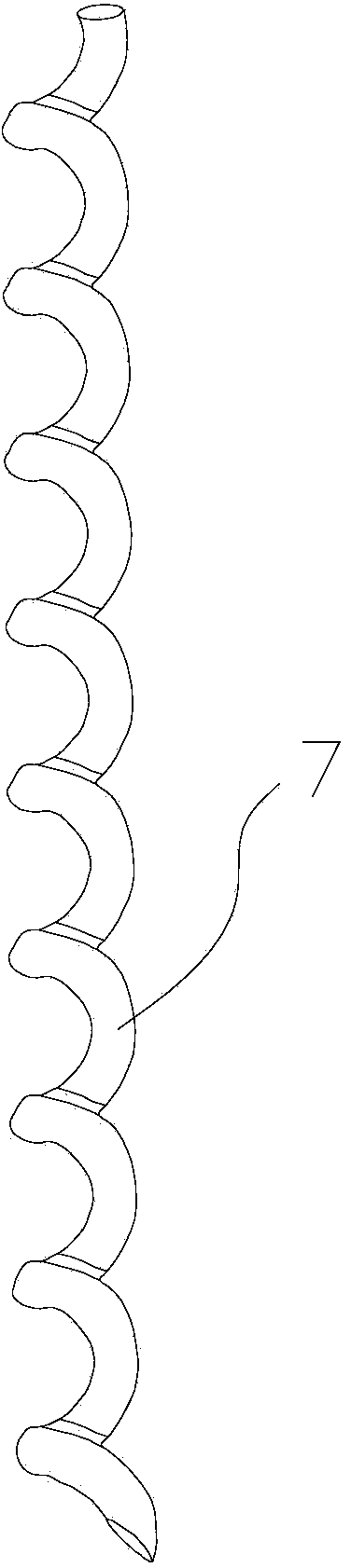

[0061] c2. Put neatly arranged strips of four colors into the piston extrusion cavity of the extrusion mechanism, and the extrusion mechanism makes a feed movement in the horizontal direction. The strip-shaped billet is extruded from the extrusion hole, and is formed into ...

Embodiment 2

[0068] The only difference from Embodiment 1 is that, as Figure 4 As shown, there are three groups of decorations hanging on the flexible necklace. The first group of decorations is a plurality of crystal beads of different shapes connected in series, and the second group of decorations is two strings of crystal beads of different shapes connected in series. The three groups of decorations are composed of a plurality of crystal beads of different shapes, decorative flowers and decorative balls connected in series.

Embodiment 3

[0070] The only difference from Embodiment 1 is that, as Figure 5 As shown, four strips of color are arranged at intervals, and the flexible spiral soft ceramic body monomers with different spiral patterns are twisted and wound with each other and connected successively end to end to form a flexible necklace with two overlapping rings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com