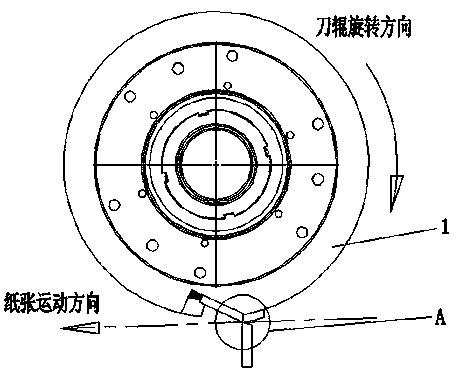

Single-rotary-cutter transverse cutting device

A cross-cutting device and single-rotation technology, which is applied in metal processing and other directions, can solve the problems that affect the quality and precision of the incision, the speed and load capacity, the blade cannot be installed vertically, and the cutting thickness is not suitable, so as to achieve working stability and shearing Improved accuracy, improved cross-cutting quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

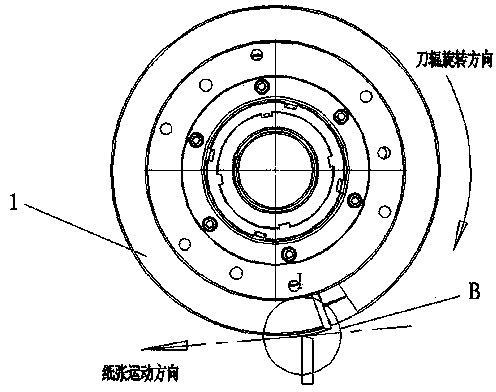

Embodiment 2

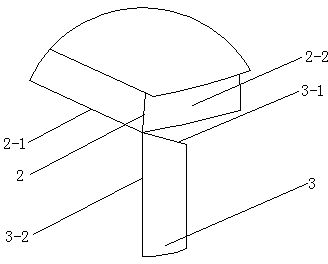

[0040] Embodiment 2 is installed in the same manner as the lower blade 3 of embodiment 1, although the upper blade of embodiment 2 is also installed on the upper knife roller 1 in the form of an Archimedes spiral surface, but the upper blade 2 of embodiment 2 adopts It is the vertical installation mode, and the upper blade 2 installation mode of embodiment 1 is horizontal, and the shearing principle of the two is then identical.

[0041] Other structures of Embodiment 2 are the same as those of Embodiment 1, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com