Automatic overturning mechanism

An automatic turning and turning shaft technology, applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve the problems of increasing mechanism complexity and design difficulty, large installation space, etc., to achieve small installation space occupation and reliable operation , the effect of simple mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

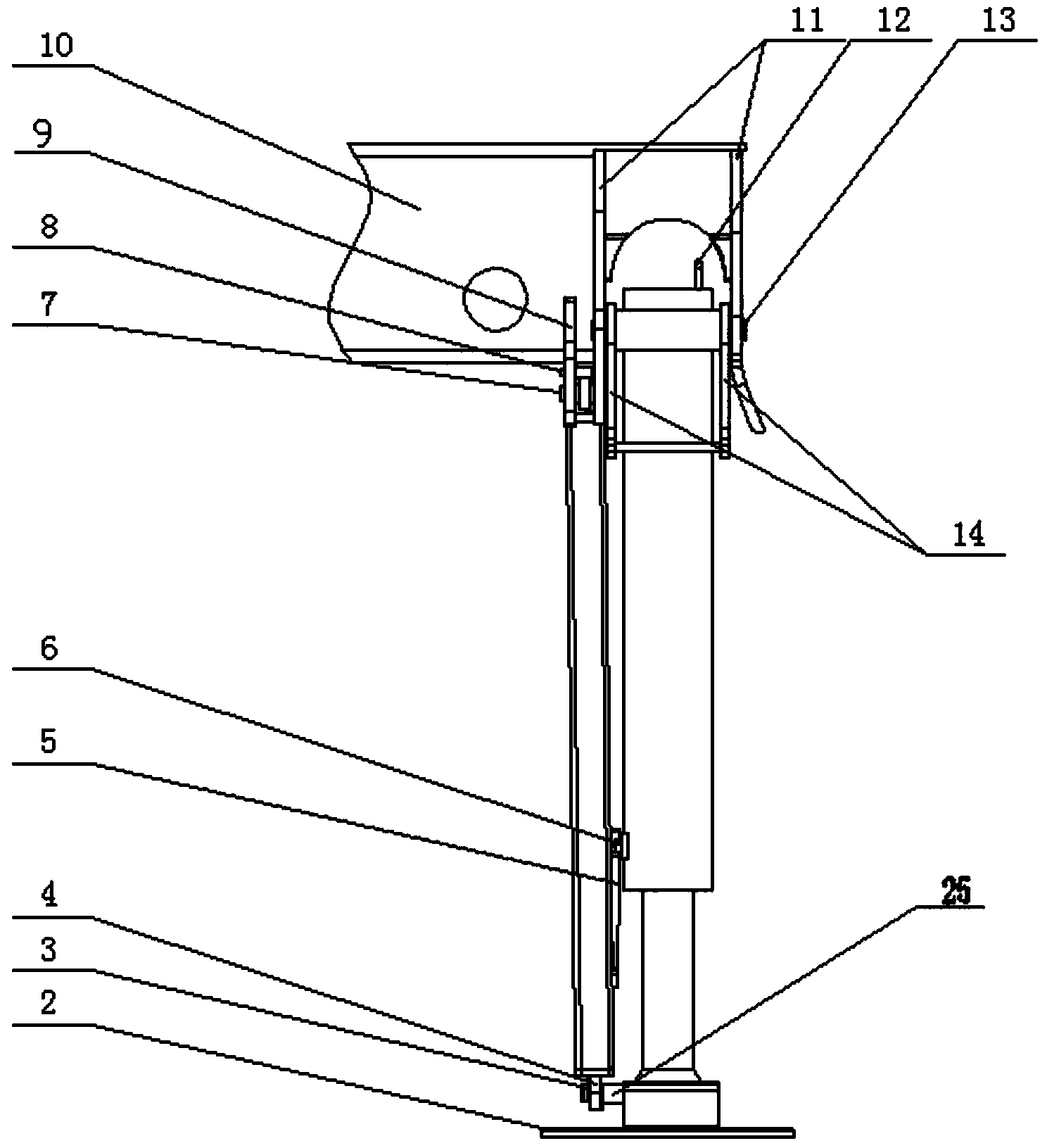

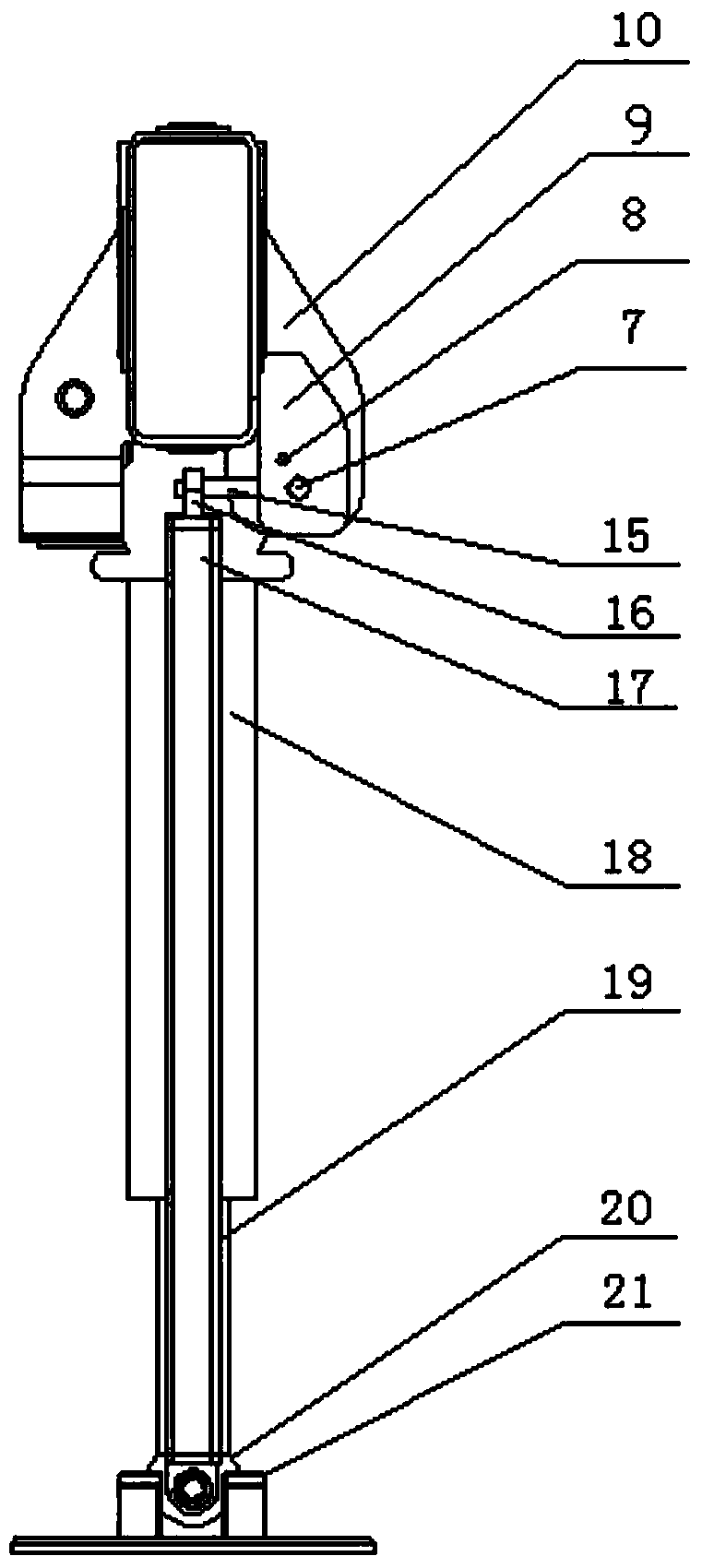

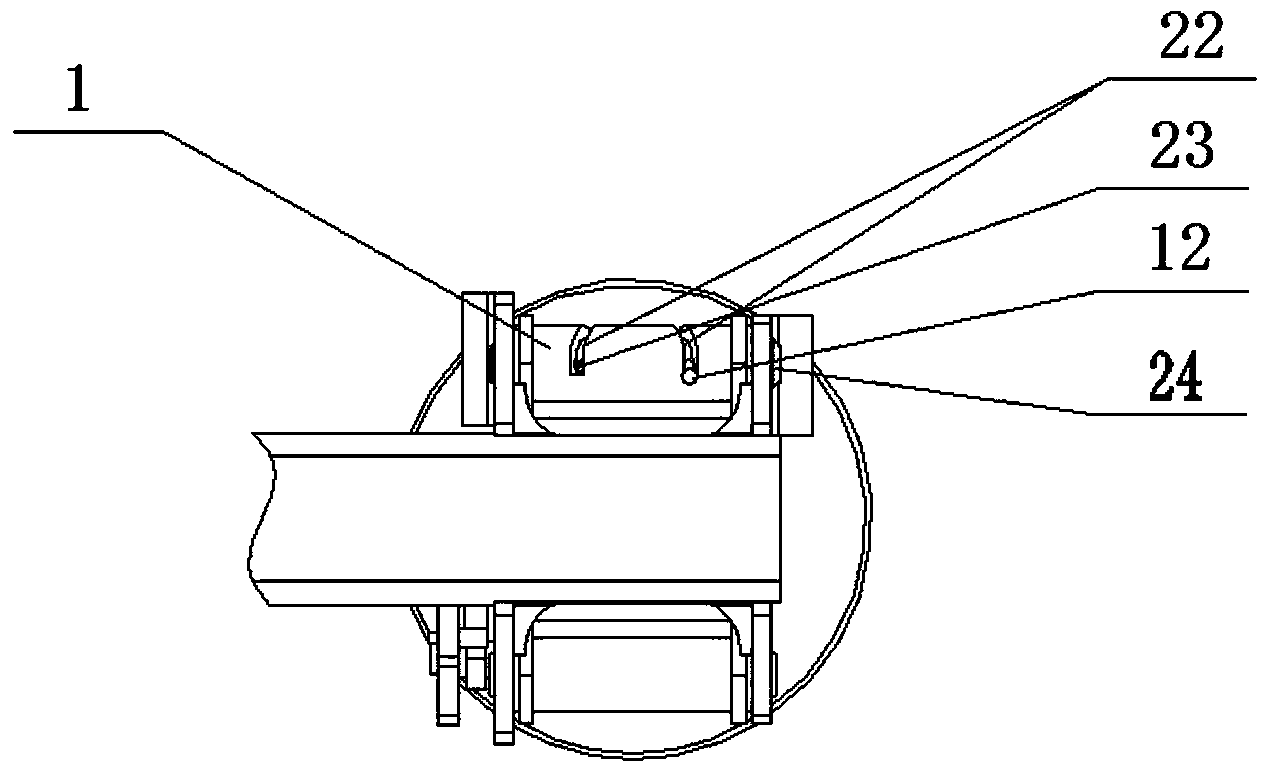

[0025] Such as Figure 1~3 The shown automatic turning mechanism includes: outrigger support plate 2, fixed lug 9, outrigger girder 10, left and right fixed support plates 11, outrigger turning shaft 13, telescopic tube 17, support plate ball hinge 20, ball Hinge retaining ring 21 and supporting legs; the upper end of the supporting legs is fixedly connected to the middle part of the supporting leg turning shaft 13, and the two ends of the supporting leg turning shaft 13 are inserted into the mounting holes of the left and right fixed support plates 11, and the left and right fixed support plates 11 and the supporting leg girder The ends of 10 are fixedly connected; the lower ends of the legs are fixedly connected with the support disk spherical hinge 20, and the support disk spherical hinge 20 is placed in the ball hinge stop ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com