Catalytic cracking unit stripper

A technology of catalytic cracking unit and stripper, which is applied in catalytic cracking, cracking, petroleum industry, etc. It can solve the problems of difficult installation, overhaul and maintenance, prone to channeling of catalyst, and low utilization rate of effective space, etc. Fixed contact time, improved contact efficiency and mass transfer efficiency, and achieved full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

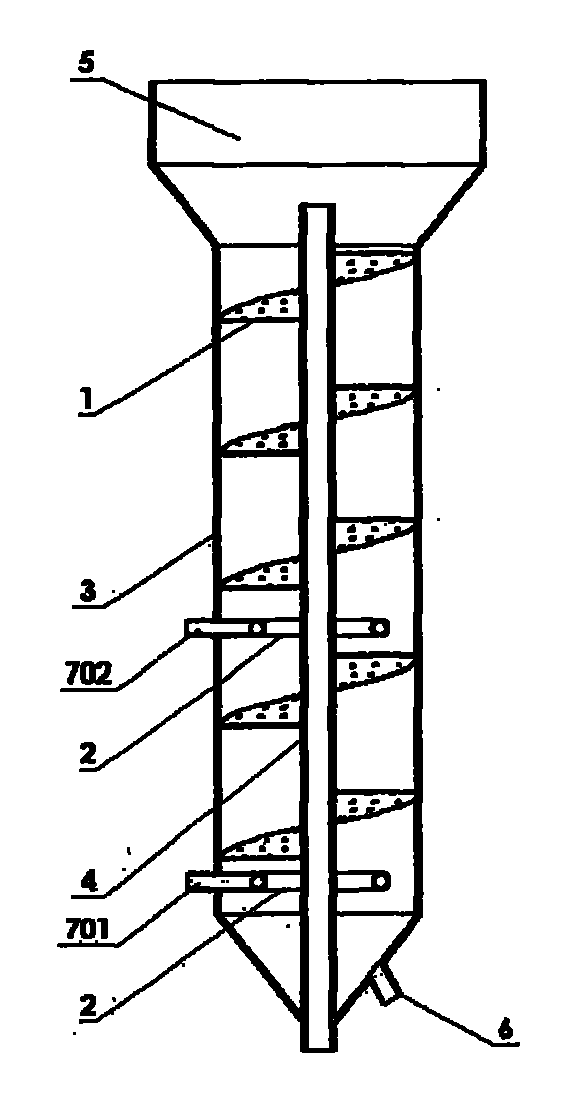

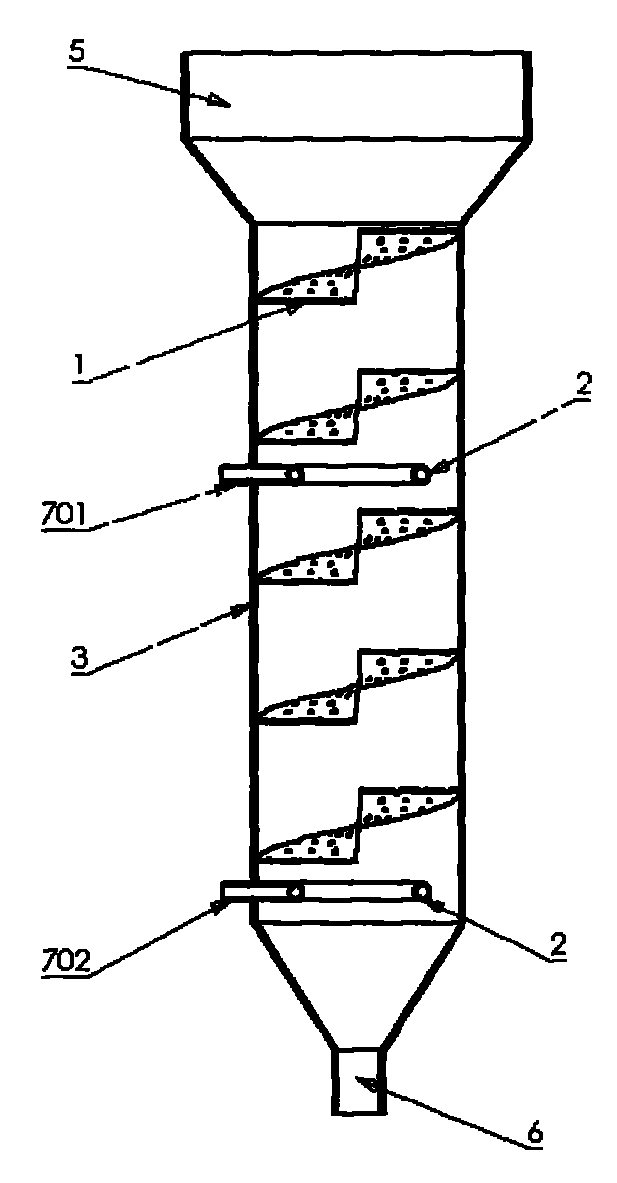

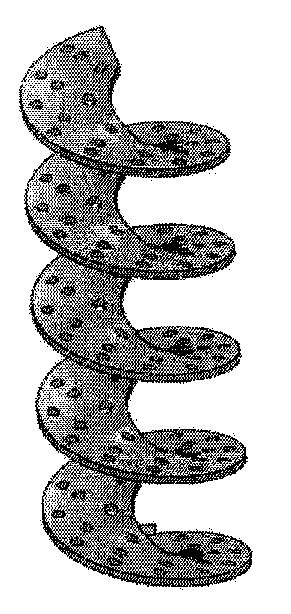

[0040] A 1 million ton / year FCC unit underwent renovation. Before the revamp, 6 sets of disc ring baffles and two-stage stripping steam distributor were used to strip the spent catalyst entrained with oil and gas from the settler. After the transformation, the spiral stripping baffles of the present invention were used to replace the 6-layer disk annular baffles before the transformation, and other structures (including two-stage stripping steam distributors) were not changed in any way. The spent catalyst from the settler entrains oil and gas into the top of the stripper. The spent catalyst first starts from the top of the equipment, flows downward through the spiral stripping baffle from top to bottom, and successively connects with the ascending first and second stages. The stripping steam is countercurrently contacted to replace the oil and gas entrained in the spent catalyst. The replaced oil gas and stripping steam flow upward into the settler, and then go to the fracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap