Machining stack structure and machining mode of light guide plates

A technology of stacking structure and light guide plate, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of waste of resources used in processing equipment, inability to guarantee work efficiency, etc., and achieve the effect of convenient operation, simple structure and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

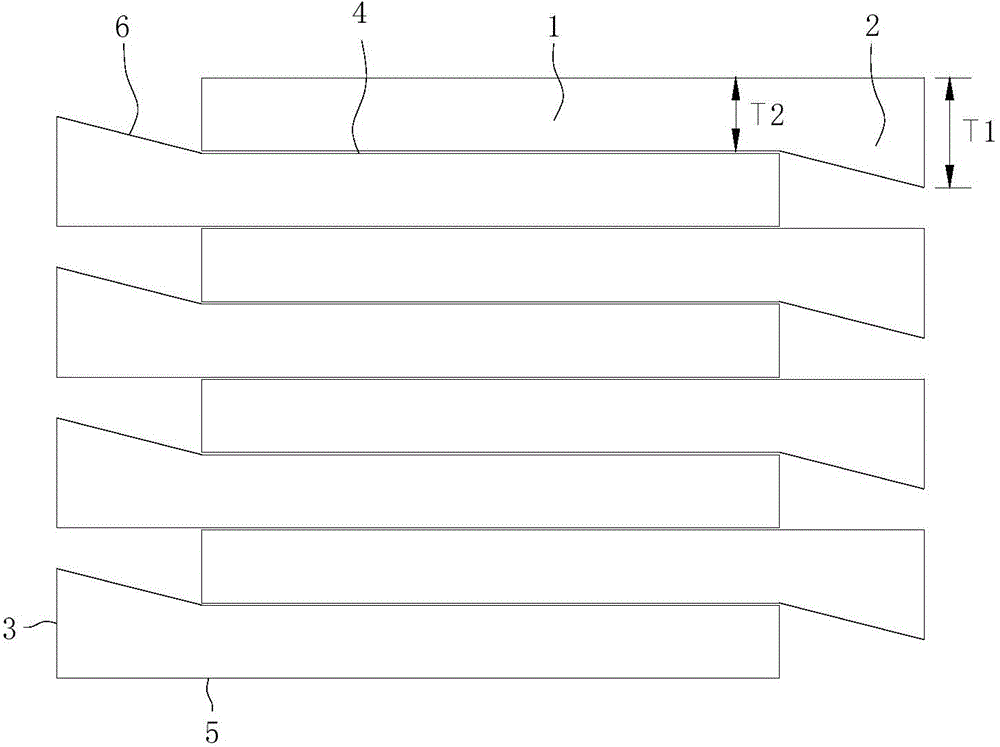

[0023] figure 1 The schematic diagram of the stacking state provided for this embodiment, the light guide plate is composed of the light guide plate main body 1 and the light incident side 2, wherein the thickness of the light guide plate main body 1 is uniform, and the integrally formed light incident side 2 is wedge-shaped, as shown in the figure, the following introduction Each side of the light guide plate mainly includes the light incident surface 3 and the inclined surface 6 of the light incident side 2 sequentially connected with the light incident surface 3, the light exit surface 4, the other side of the light incident surface is connected with the bottom surface 5, and the bottom surface 5 is connected with the light exit surface. Corresponding to surface 4, the thickness T1 of the light incident side 2 is less than twice the thickness T2 of the light guide plate main body 1, which is greater than the thickness T2 of the light guide plate main body 1. During processin...

Embodiment 2

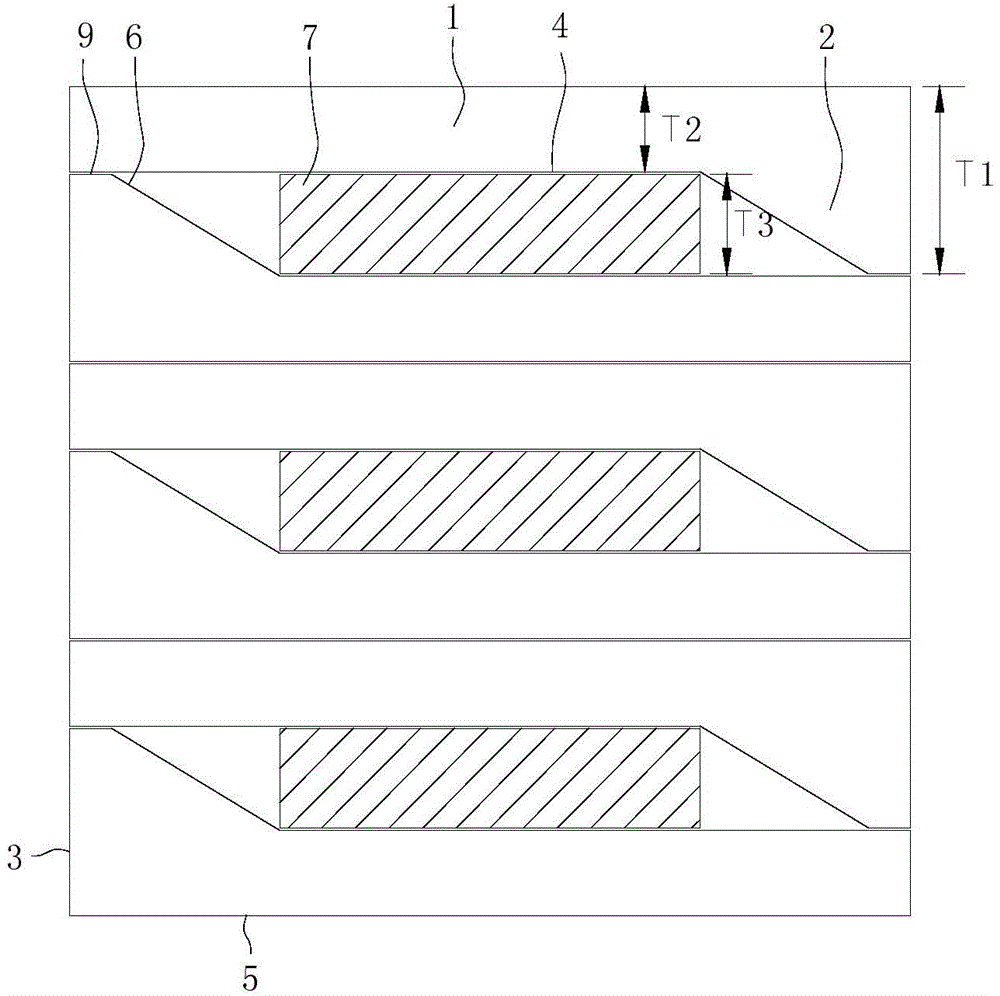

[0026] figure 2 A schematic diagram of the stacked state of another structural light guide plate provided for this embodiment. As shown in the figure, the thickness T1 of the light incident side 2 is greater than twice the thickness T2 of the light guide plate main body 1. If two When using light guide plates, the light incident side 2 of one of the light guide plates must be higher than the bottom surface 5 of the other light guide plate, which is not conducive to batch processing of the light guide plates. The structure of the light guide plate in this embodiment also includes the slope 6 of the light incident side 2 and The plane 9 between the light surfaces 3, the plane 9 is parallel to the bottom surface 5, and in this embodiment, when the light guide plates are stacked in pairs, the plane 9 on the light incident side 2 of one of the light guide plates is not the same as the light exit surface of the other light guide plate 4 are attached to each other, so that there mus...

Embodiment 3

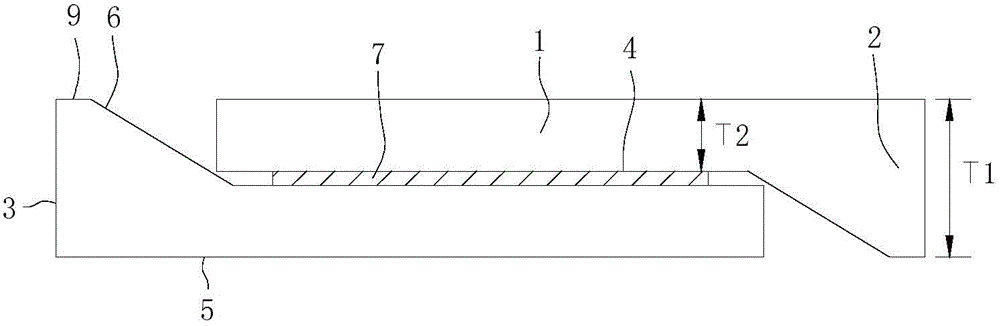

[0029] Such as image 3 As shown, the difference between this embodiment and embodiment 2 is that when two light guide plates are stacked, similar to embodiment 1, the light incident side 2 of one light guide plate is located on one side of the other light guide plate and its The top surface of the part higher than the light-emitting surface 4 of itself, that is, the plane 9, is equal to the bottom surface 5 of the other light guide plate, so that the distance between the light-emitting surfaces 4 of the two light guide plates can be reduced, and the volume of the backing plate 7 in the middle can be made Even smaller, when multiple such light guide plates are stacked, the volume will be effectively reduced. In this embodiment, the thickness T3 of the backing plate is greater than the sum of the thickness T1 of the light-incident side and the thickness T2 of the main body of the light guide plate. Friction between light plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com