Control method for fast cutting of spraying rail

A control method and rapid cutting technology, applied in the field of mechanical processing, can solve the problems of time-consuming cutting, low safety and reliability, etc., and achieve the effects of protecting the saw blade, reducing energy consumption, and preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

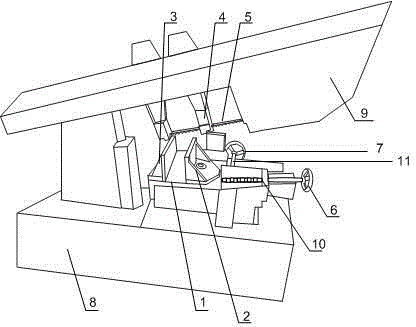

[0020] Such as figure 1 As shown, the present invention first places the spray rail on the cutting machine, and then adjusts the spray rail clamping mechanism to move close to or away from the position in the direction of the saw blade through the adjustment mechanism. Move to meet the needs of cutting the spray rail, the spray rail clamping mechanism can hold one or more than one spray rail main material, turn the second hand wheel to make the spray rail main material move to the direction of the saw blade, start the band saw machine, Complete the cutting of the spray rail; the band saw machine is set on the mechanical arm 9, and the mechanical arm 9 is connected to the machine tool 8, including the spray rail clamping mechanism 1 and the adjustment mechanism, and the spray rail clamping mechanism 1 is slidably set on the machine tool 8 for operation On the stage, the spray rail clamping mechanism 1 is connected with the adjusting mechanism provided on the machine tool 8 . T...

Embodiment 2

[0022] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the first hand wheel 6 is rotated, so that the movable baffle 2 moves to the right, and the distance between the fixed baffle 3 is increased to place more cutting main materials, After the spray rail main material is placed on the spray rail clamping mechanism 1 in batches, the first hand wheel 6 is rotated to make the spray rail clamping mechanism 1 clamp the main material.

Embodiment 3

[0024] Such as figure 1 As shown, the present embodiment is on the basis of Embodiment 1, and the adjustment mechanism includes a second hand wheel 7 and a second screw 10, the second screw 10 is arranged on the operating table of the machine tool, and the second screw 10 and the operating table of the machine tool are threaded, one end of the second screw rod 10 is connected with the second handwheel 7, the other end of the second screw rod 10 is in contact with the connecting plate, and the second handwheel 7 passes through the second screw rod 10 links to each other with spray rail clamping mechanism 1. Through the connecting plate, the second screw rod 10 connects the spray rail clamping mechanism 1 with the second hand wheel 7, and rotating the second hand wheel 7 can make the spray rail clamping mechanism 1 move freely in the direction close to or away from the saw blade 5, To facilitate saw blade 5 cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com